Anti-static film and preparation method thereof

An antistatic and film technology, applied in the field of antistatic film and its preparation, can solve the problems of short antistatic time, poor compatibility between antistatic agent and film material, achieve long-lasting antistatic effect, improve antistatic effect, strong Effects of Affinity and Compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

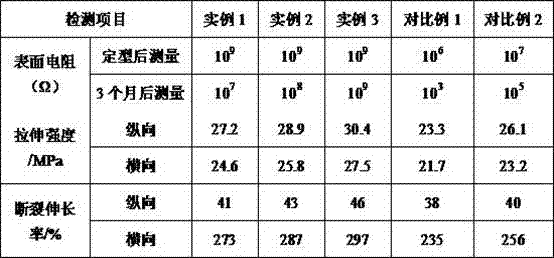

Examples

example 1

[0025] Take 10g of dimethyl diallyl ammonium chloride and 100mL of absolute ethanol into a three-necked flask equipped with a thermometer and a reflux device, place the three-necked flask in a water bath, control the temperature of the water bath to 85°C, and stir and mix for 3 minutes , add 8g sodium methpropylene sulfonate, 6g ethylene glycol monovinyl ether and 0.3g lauroyl peroxide to the three-necked flask, stir and react for 2h, then add 3g p-tert-butylcatechol to the three-necked flask, continue stirring React for 40 minutes, the reaction is over, and the product is obtained. The product is placed in a rotary evaporator, and concentrated by rotary evaporation for 15 minutes to obtain a concentrated solution. Then take 20g of polystyrene and 200mL of methyl ethyl ketone and add it to a three-port tube with a thermometer and a reflux device. In the flask, place the three-necked flask in an oil bath, control the temperature of the oil bath to 130°C, stir and dissolve for 3 ...

example 2

[0027] Take 13g of dimethyl diallyl ammonium chloride and 150mL of absolute ethanol into a three-necked flask equipped with a thermometer and a reflux device, place the three-necked flask in a water bath, control the temperature of the water bath to 90°C, and stir and mix for 4 minutes , add 10g sodium methpropylene sulfonate, 7g ethylene glycol monovinyl ether and 0.4g potassium persulfate to the three-necked flask, stir and react for 2h, then add 4g p-tert-butylcatechol to the three-necked flask, continue to stir and react After 45 minutes, the reaction was completed, and the product was obtained. The product was placed in a rotary evaporator, concentrated by rotary evaporation for 18 minutes, and a concentrated solution was obtained. Then, 25 g of polystyrene and 250 mL of methyl ethyl ketone were added to a three-necked flask with a thermometer and a reflux device. In the three-necked flask, place the three-necked flask in an oil bath, control the temperature of the oil bat...

example 3

[0029]Take 15g of dimethyl diallyl ammonium chloride and 200mL of absolute ethanol into a three-necked flask equipped with a thermometer and a reflux device, place the three-necked flask in a water bath, control the temperature of the water bath to 95°C, and stir and mix for 5 minutes , add 12g sodium methpropylene sulfonate, 8g ethylene glycol monovinyl ether and 0.5g tert-butyl hydroperoxide to the three-necked flask, stir and react for 3h, then add 5g dimethyldithioamino to the three-necked flask Sodium formate, continue to stir and react for 50min, after the reaction is over, the product is obtained, the product is placed in a rotary evaporator, concentrated by rotary evaporation for 20min, to obtain a concentrated solution, and then 30g of polystyrene and 300mL of methyl ethyl ketone are added to a thermometer with a thermometer and In the three-necked flask of the reflux device, place the three-necked flask in an oil bath, control the temperature of the oil bath to 140°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com