Preparation method and application of long-acting microalgae biological hydrogen production system

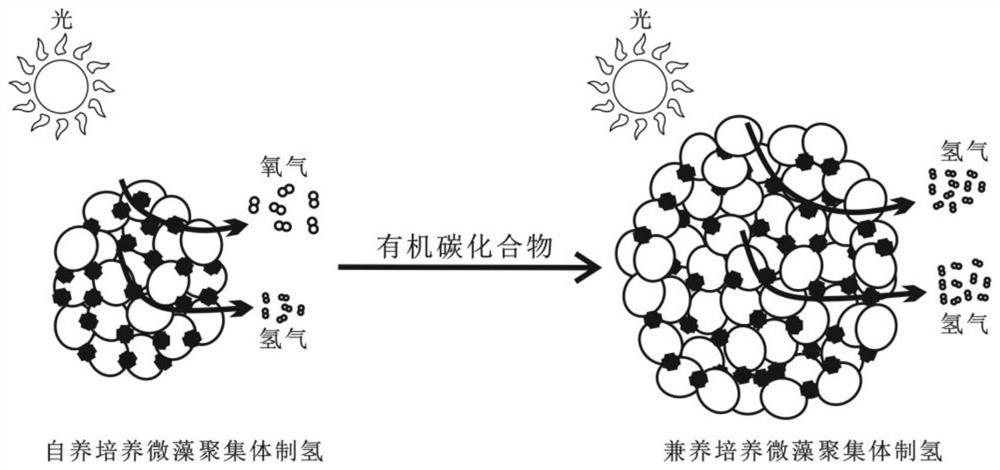

A technology of biology and microalgae, which is applied in the field of preparation of microalgae biological hydrogen production system, can solve the problem that the cost and efficiency of microalgae hydrogen production are difficult to balance, reduce the demand for dissolved oxygen and light, and maintain hydrogen production activity , the effect of promoting consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

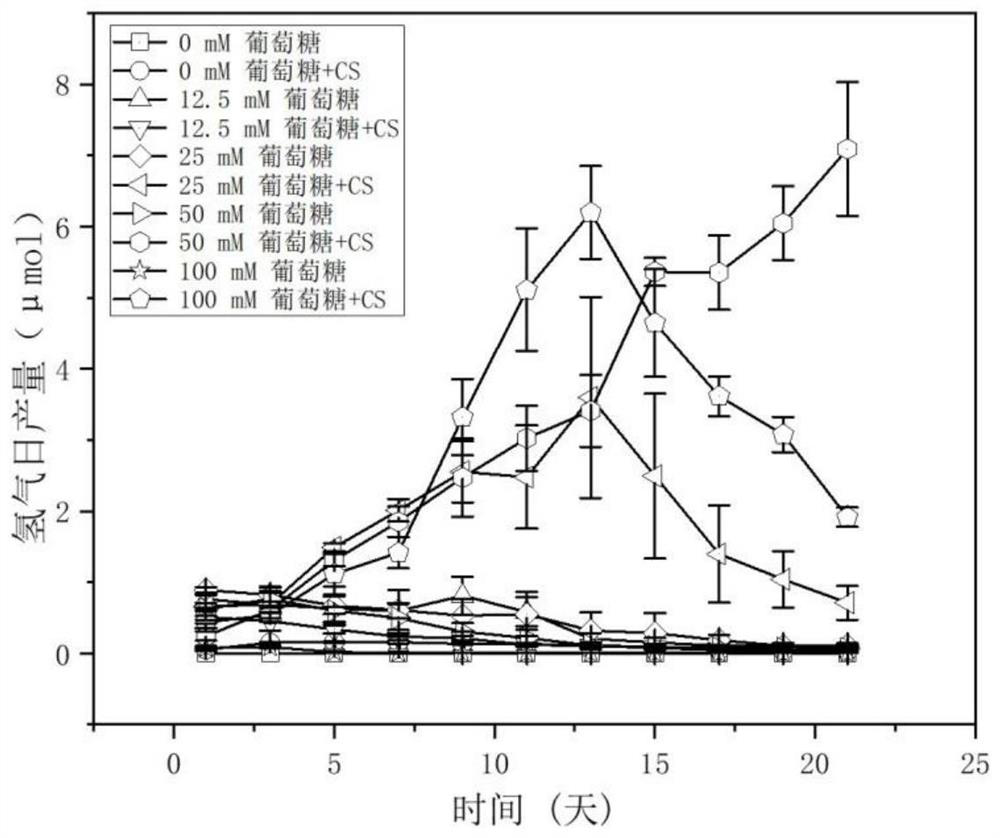

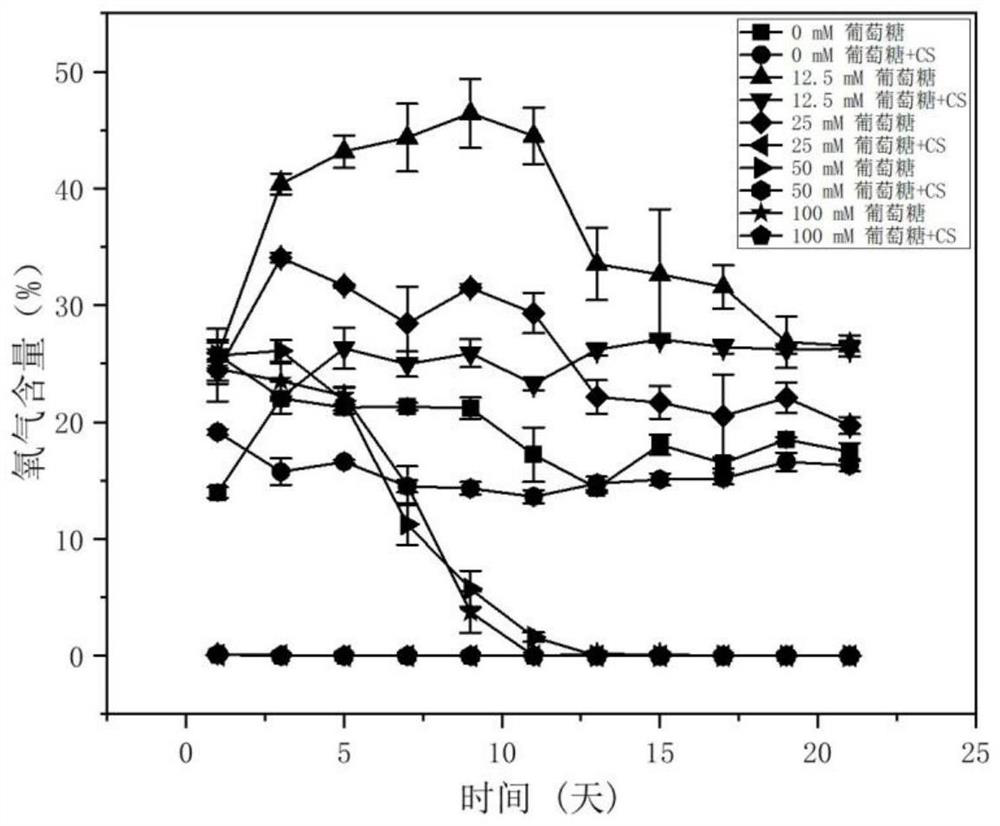

[0042] This example provides a long-term preparation method of a microalgae biological hydrogen production system. It should be understood that this is only an example and not a limitation. The microalgae, liquid medium, and flocculant selected in this example , and organic carbon compounds, respectively Chlorella pyrenoidosa, TAP medium, cationic etherified starch, and glucose.

[0043] First use TAP medium to cultivate Chlorella pyrenoidosa, when the light absorption of the culture at 750nm reaches 0.3 (OD750=0.3), add glucose and cationic etherified starch to the Chlorella pyrenoidosa liquid culture to make it The aggregates of Chlorella pyrenoidosa were produced by flocculation under near-neutral pH conditions and entered into a mixed culture mode, and then gas chromatography was used to monitor the content of oxygen and hydrogen in the culture system. A gas chromatograph is used to monitor the change of oxygen and hydrogen content in the photobiological hydrogen productio...

Embodiment 2

[0054] Analysis of the effect of different glucose concentrations on the effect of CS flocculin Chlorella nuclei. A microplate reader was used to test the photometric absorption of the supernatant of the hydrogen production system prepared in Example 1 at 750 nm to analyze the flocculation of Chlorella pyrenoidosa in the system.

[0055] The result is as Figure 5 As shown, 12.5mM glucose can significantly enhance the photometric absorption at 750nm of the supernatant of the culture system of Chlorella pyrenoidosa without CS flocculation, and the photometric absorption of the supernatant at 750nm in the culture system adding CS, They are also higher than other culture systems flocculated by CS, which shows that 12.5mM glucose can promote the growth of Chlorella pyrenoidosa, thereby reducing the flocculation effect of limited amount of CS on Chlorella pyrenoidosa. Although 25mM glucose can also significantly enhance the photometric absorption at 750nm of the supernatant of Chl...

Embodiment 3

[0057] Observation and analysis of aggregates of Chlorella pyrenoidosa under mixed culture. The production of Chlorella pyrenoidosa aggregates in the hydrogen production system prepared in Example 1 and the size of the aggregates were observed and analyzed by an optical microscope.

[0058] The results of microscopic observations such as Figure 6 (The scale in the figure is 300 μm) As shown, after CS flocculation of Chlorella pyrenoidosa under combined culture, significant aggregates of Chlorella pyrenoidosa were produced in the original culture system. Among them, at the concentration of 50mM glucose, the aggregates of Chlorella pyrenoidosa formed most obviously in the culture system. The concentrations of 100mM, 25mM, and 12.5mM glucose followed successively. In addition, at the concentration of 12.5 mM glucose, the effect of CS flocculated Chlorella pyrenoidosa on forming aggregates was inferior to that of CS flocculated Chlorella pyrenoidosa aggregates formed under phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com