Composite heat source flexible clean heat supply method and system based on cross-seasonal graded heat storage

A composite heat source, flexible and clean technology, applied in heating systems, solar heating systems, heating methods, etc., can solve the problems of system initial investment and operation cost reduction, reduce power consumption, enhance flexibility and adjustability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

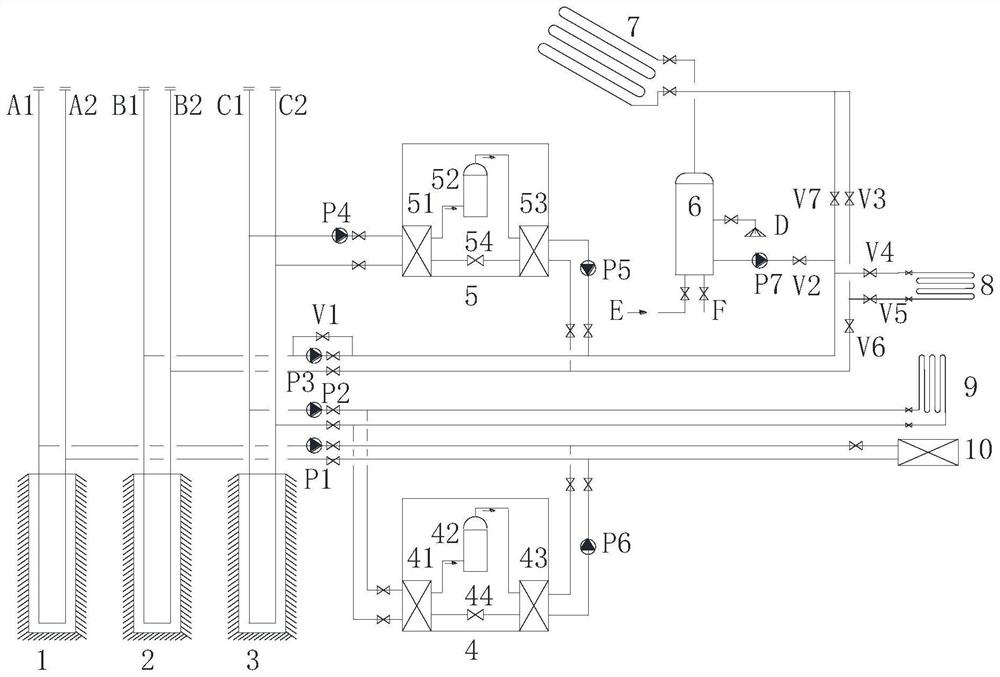

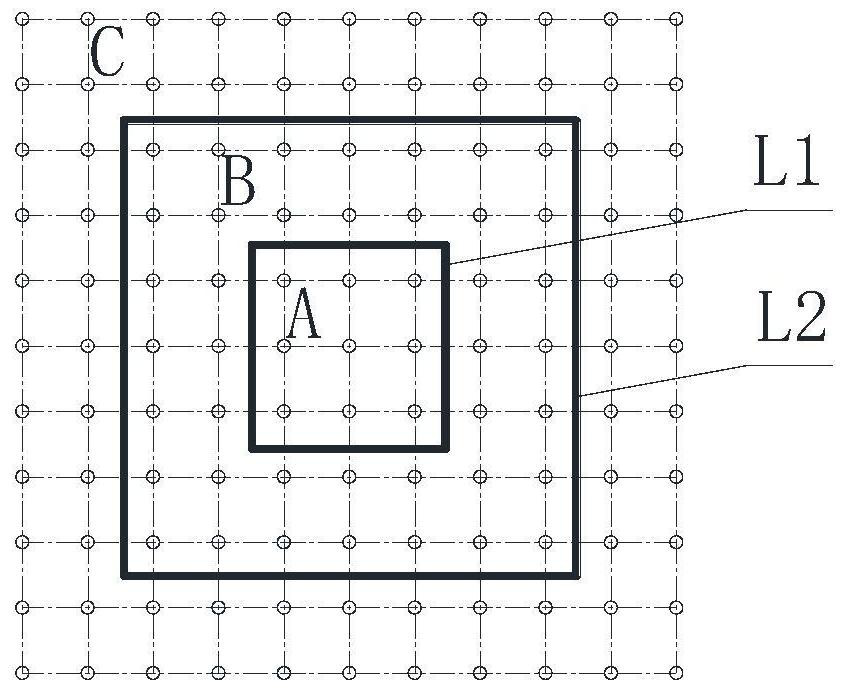

[0045] figure 1 is the system schematic diagram of this patent, figure 2 It is a step-by-step schematic diagram of well drilling for cross-seasonal multi-stage heat storage of this patent.

[0046] The specific description of this patent is: a method and system for flexible and clean heating of composite heat sources based on cross-seasonal graded heat storage. The pipeline system is composed of the soil source graded heat storage system consisting of 3 groups of buried pipes, of which the inner stratum heat storage area A is the heat storage pipe group 1 in the high temperature area, and the middle stratum heat storage area B is the heat storage pipe in the middle temperature area Group 2, the formation heat storage area C in the outer circle is the heat storage pipe group 3 in the low temperature area, the virtual high temperature boundary L1 is between the heat storage pipe group 1 in the high temperature area and the heat storage pipe group 2 in the medium temperature ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com