Microstrip line-based strip electron beam focusing method, device and application

A strip-shaped electronic and focusing device technology, which is applied in the direction of time-of-flight electron tubes, circuits, discharge tubes, etc., can solve the problems of aggravated focusing difficulty, Diocotron instability, and longer time, so as to achieve good focusing effect and unstoppable suppression. The effect of stability and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A focusing method of a strip-shaped electron beam based on a microstrip line, comprising: generating an electric field in the space where the microstrip line exists, and the electric field makes the edges of the strip-shaped electron beam of the microstrip line equipotential.

[0037] The invention is based on a stable condition of the focus of the ribbon-shaped electron beam, that is, when the edge of the ribbon-shaped electron beam is equipotential, the ribbon-shaped electron beam can be stably transmitted.

[0038] However, this stable condition is not a conventional technical means for those skilled in the art. This is because, in general, the ribbon-shaped electron beam is focused by a uniform magnetic field, but since the space charge field distribution of the ribbon-shaped electron beam is not axisymmetric, a very high magnetic field is required for focusing.

[0039] In order to study the instability of the ribbon-shaped electron beam in a uniform magnetic field...

Embodiment 2

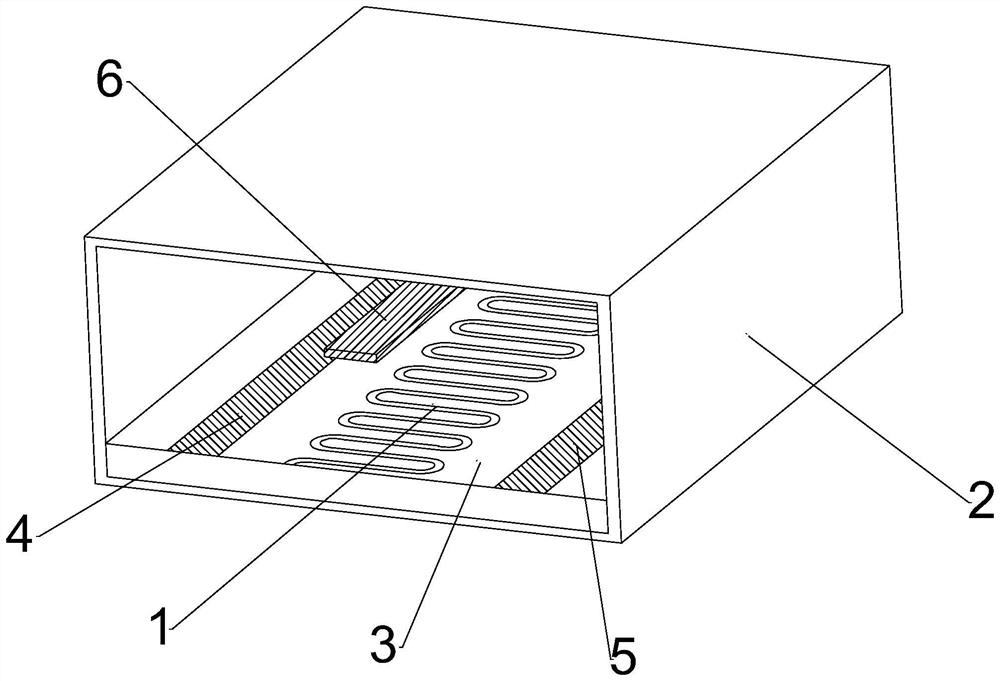

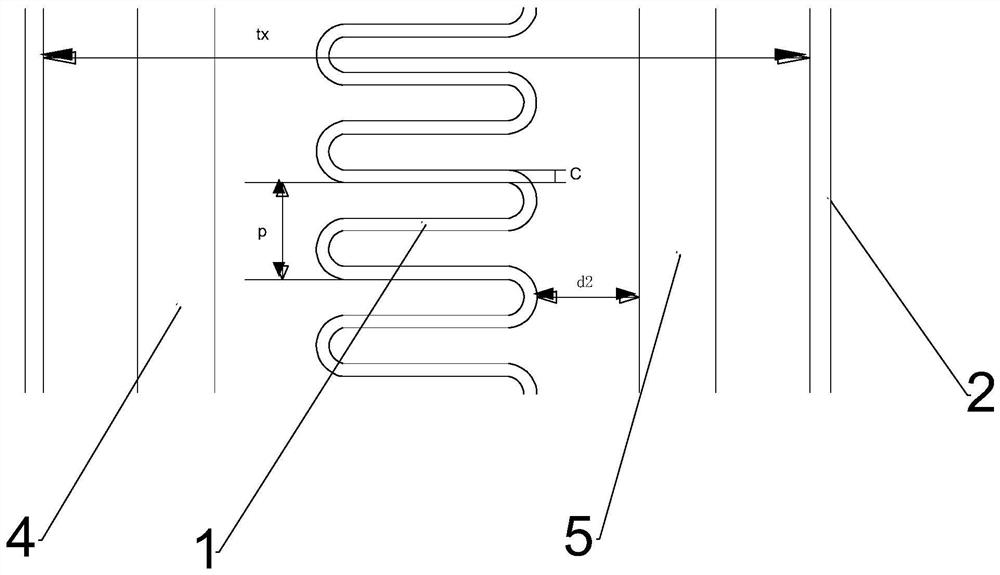

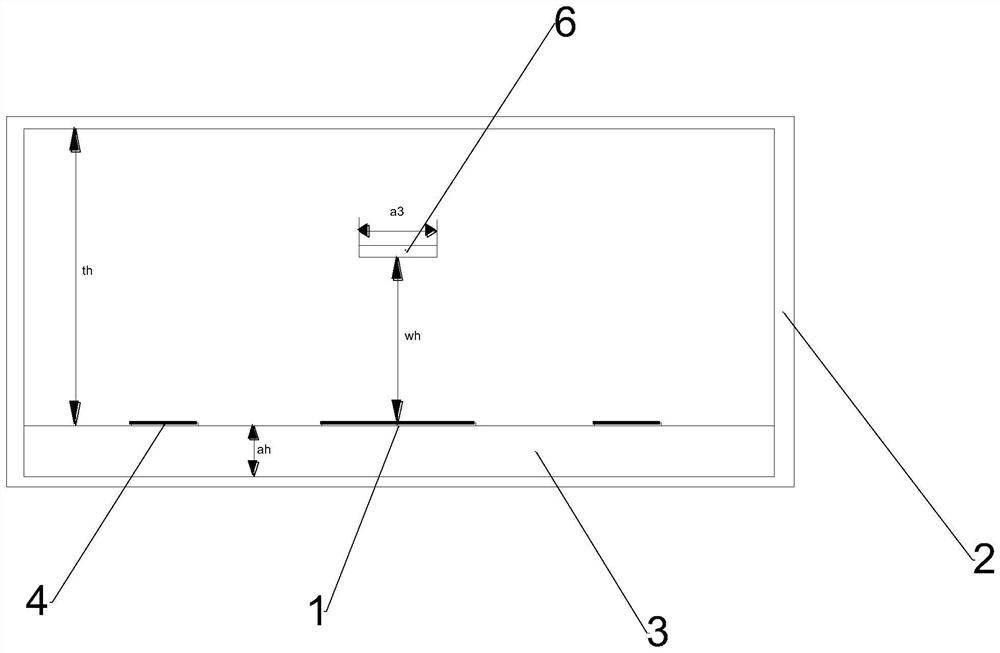

[0046] Such as figure 1 As shown, a focusing device based on a strip-shaped electron beam of a microstrip line is used to implement a focusing method of a strip-shaped electron beam of a microstrip line, including a metal shell 2, a microstrip line 1, a dielectric substrate 3 and several metal wires (4, 5, 6), the length direction of the metal wire is set with the moving direction of the strip-shaped electron beam. In this embodiment, the microstrip line 1 is sinusoidal, and the direction of its periodic extension is the strip-shaped electron beam. The direction of motion, specifically, such as figure 2 As shown, the width of the microstrip line 1 is a, the period length is p, and the line width is c.

[0047] Since the space charge field in the existing microstrip vacuum electronic device does not meet this condition, a number of metal wires are added to the microstrip vacuum electronic device, and then voltage is applied to the channel wall, the metal wire, and the microst...

Embodiment 3

[0057] A kind of application of the strip electron injection based on microstrip line, comprises the steps:

[0058] Apply the above-mentioned focusing device to fields including but not limited to high-resolution radar, high-speed data communication, electronic attack, and radio astronomy;

[0059] The focusing device needs to be debugged before application, and the debugging method is as follows:

[0060] Applying a voltage to both ends of the microstrip line of the focusing device, thereby generating a strip-shaped electron beam;

[0061] An electric field is generated in the space in the metal channel of the focusing device, so that the edges of the strip-shaped electron beam of the microstrip line of the focusing device are equipotential.

[0062] In this embodiment, an electric field is generated in the space in the metal channel of the focusing device, so that the edge equipotential of the strip-shaped electron beam of the microstrip line of the focusing device is spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com