Anti-fouling device for heat exchanger and use thereof

A technology of heat exchangers and heat exchanger tubes, applied in heat exchange equipment, heat exchange equipment safety devices, indirect heat exchangers, etc., can solve the problems of high device cost, increased control and maintenance, and increased mechanical complexity and sensitivity of the system In order to achieve the effects of avoiding fouling, easy installation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

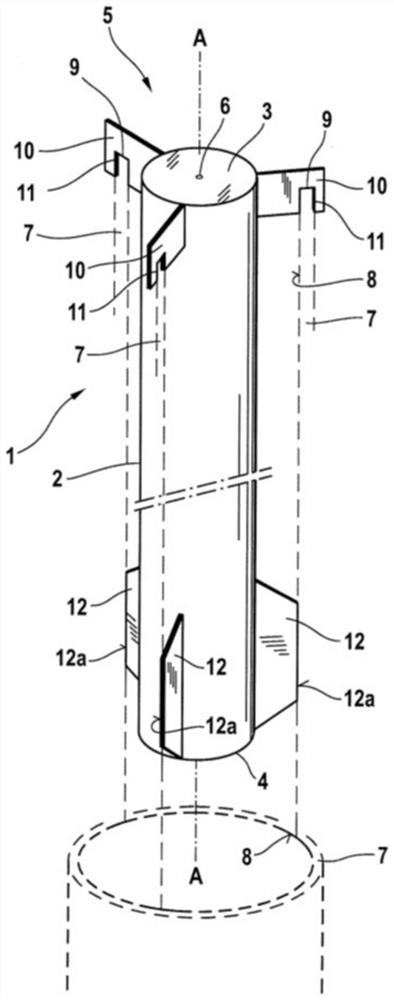

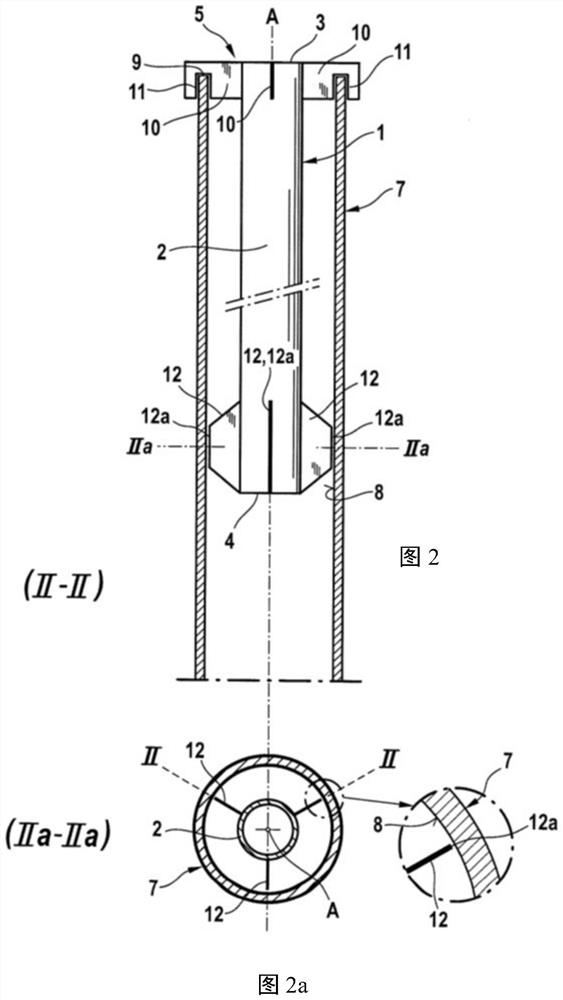

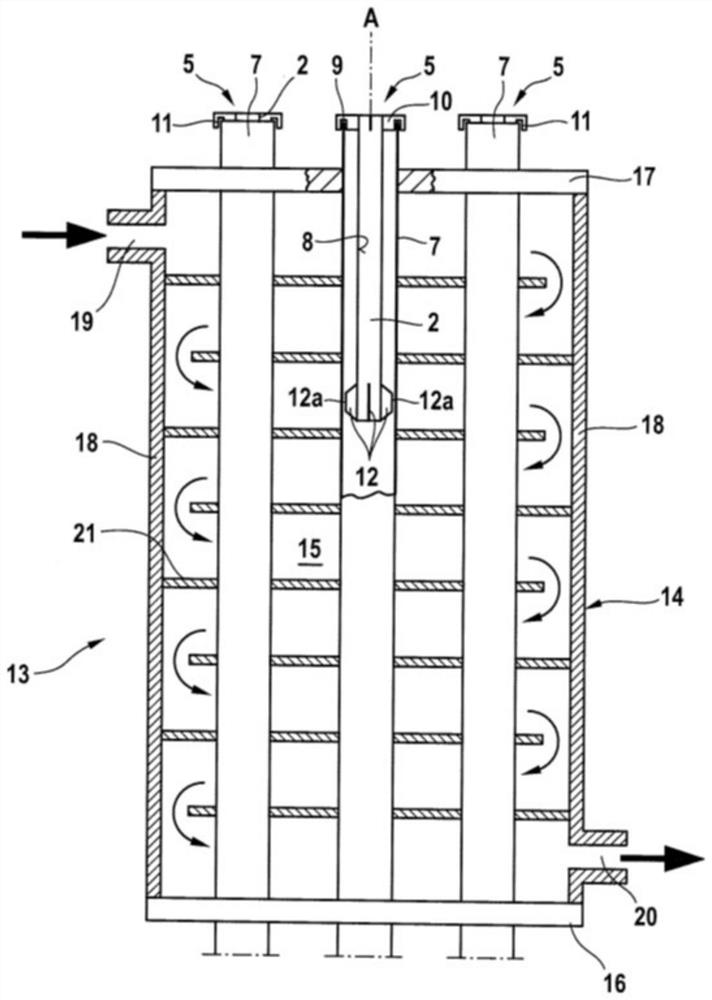

[0041] As stated above, the present invention relates to a device for reducing fouling in heat exchanger tubes, also referred to herein as an "anti-fouling device". The anti-fouling device according to the present invention comprises an elongated displacer configured to be inserted into a heat exchanger tube to reduce the flow cross-sectional area in a portion of the tube. As used herein, the term "flow cross-sectional area" refers to the cross-sectional area of a tube that is available for a fluid, such as a gas, to flow through the tube. For the sake of clarity, the cross-section of the tube refers to the cross-section in a plane perpendicular to the main axis of the tube. The main axis of the tube refers to the figure 2 The central axis along its direction of the hollow passage formed by the closed tube wall is shown, and is labeled axis "A" therein. The term "displacement body" as used herein refers to a physical body which, when introduced into the flow path of a flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com