Composite molecular sieve catalyst, preparation method and application thereof

A technology of composite molecular sieve and catalyst, which is applied in molecular sieve catalyst, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of difficult acid control of catalyst and low xylene selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] According to one embodiment of the present invention, it relates to a preparation method of a composite molecular sieve catalyst, comprising the following steps:

[0049] Mix ZSM-48 molecular sieve, ZSM-11 molecular sieve, aluminum dihydrogen phosphate and forming aids evenly, then add alkaline earth metal salt solution, extrude, form, and then dry and roast to obtain composite molecular sieve catalyst.

[0050] In the above technical solution, the ZSM-48 molecular sieve, the ZSM-11 molecular sieve, and the aluminum dihydrogen phosphate are in a weight ratio of 40-60:9-46:14.9-27.

[0051] According to an embodiment of the present invention, in the preparation step, the kneading temperature is not particularly limited, and can be arbitrarily selected by those skilled in the art, but is generally 10-40°C, preferably 10-30°C.

[0052] According to an embodiment of the present invention, in the preparation step, the kneading time is not particularly limited, and can be arb...

Embodiment 1

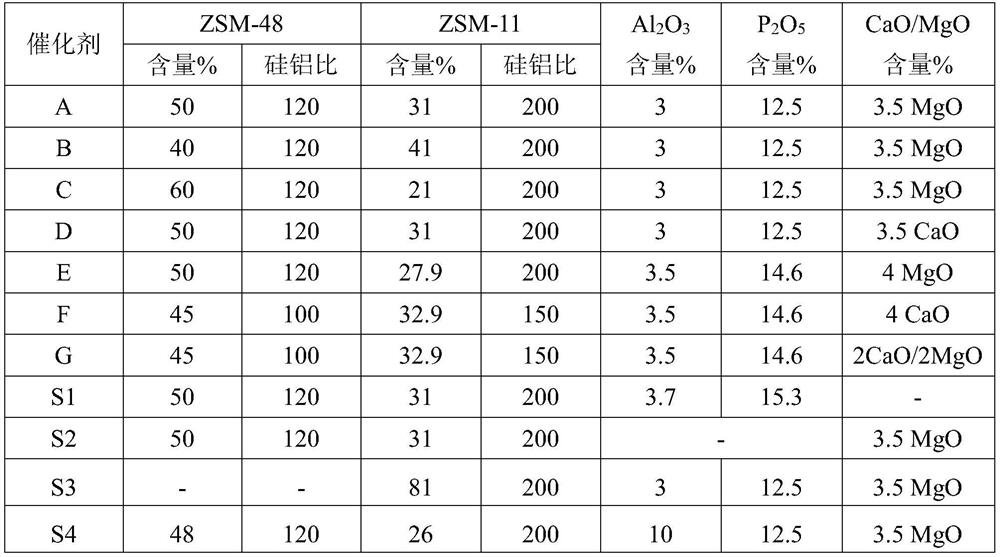

[0069] The dry basis of 50g ammonium type ZSM-48 molecular sieve (SiO 2 / Al 2 O 3 Molar ratio of 120), dry basis 31g ammonium type ZSM-11 molecular sieve (SiO 2 / Al 2 O 3 The molar ratio is 200), 18.8g of aluminum dihydrogen phosphate and 4g of succulent powder are mixed uniformly in the kneader, and the magnesium nitrate solution with a weight concentration of 50% is added to the kneader and kneaded for 30 minutes to obtain a dough shape. A cylindrical bar with a diameter of 1.7 mm was dried at 120° C. and calcined in an air atmosphere at 550° C. to obtain catalyst A. The composition of catalyst A is shown in Table 1.

Embodiment 2

[0071] The dry basis of 40g ammonium type ZSM-48 molecular sieve (SiO 2 / Al 2 O 3 The molar ratio is 120), 41g dry basis of ammonium type ZSM-11 molecular sieve (SiO 2 / Al 2 O 3 The molar ratio is 200), 18.8g of aluminum dihydrogen phosphate and 4g of succulent powder are mixed uniformly in the kneader, and the magnesium nitrate solution with a weight concentration of 50% is added to the kneader and kneaded for 30 minutes to obtain a dough shape. A cylindrical bar with a diameter of 1.7 mm was dried at 120° C. and calcined in an air atmosphere at 550° C. to obtain catalyst B. The composition of catalyst B is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com