Method and device for regulating and controlling conductivity of graphene metal laminated composite material

A metal lamination and composite material technology, applied in graphene, lamination devices, non-metallic elements, etc., can solve the problem of unsuitable conductor material requirements, shorten the production cycle, reduce the number of heating and cooling, and reduce operations. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

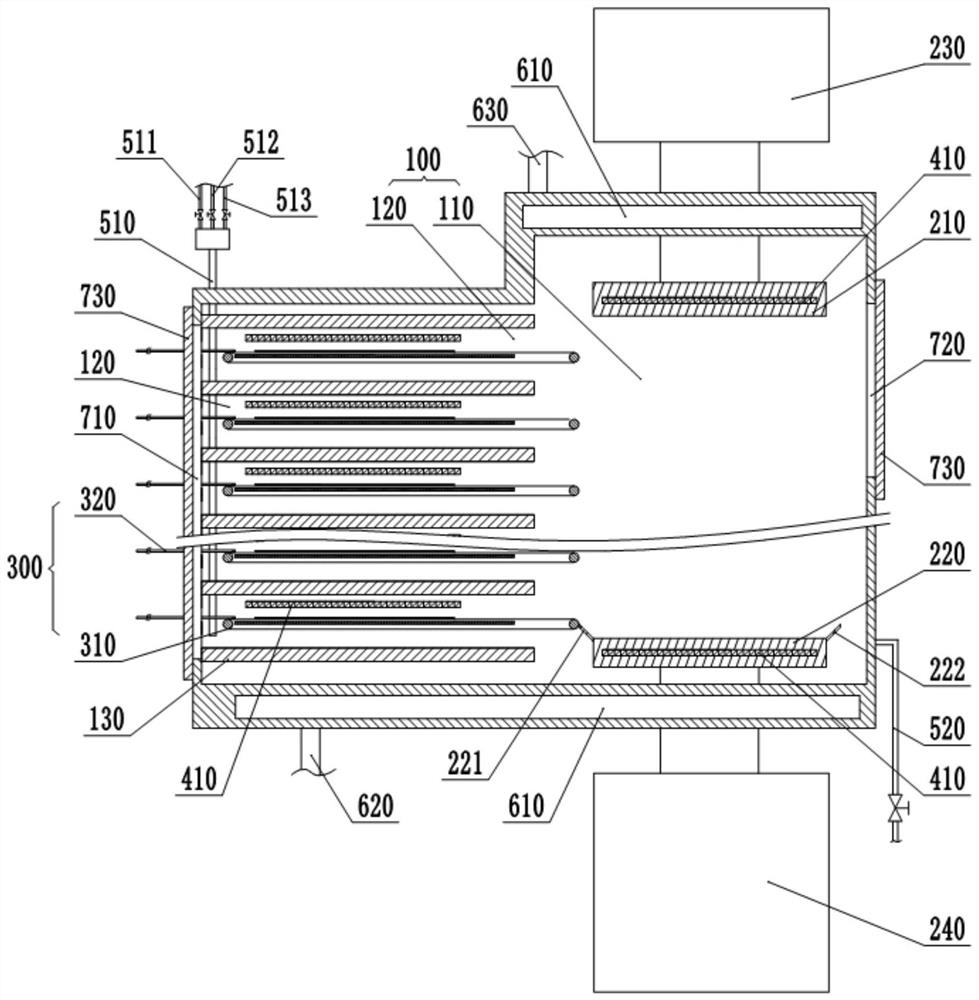

[0056] This embodiment is basically as figure 1 Shown: a graphene metal laminated composite conductivity control device, including an integrated chamber 100, a heating system, and a gas system that ventilates into the integrated chamber 100 and discharges the gas in the integrated chamber 100. The integrated chamber 100 is provided with a main chamber 110, a transfer mechanism 300 and several sub-chambers 120 communicating with the main chamber 110. In this embodiment, the number of sub-chambers 120 is twenty-two. Yes, those skilled in the art can design an appropriate number of sub-chambers 120 in the integrated chamber 100 according to the actual situation. The sub-chamber 120 in this embodiment is formed by separating the space on the left side of the integrated chamber 100 by a plurality of heat-insulating partitions 130 .

[0057] The main chamber 110 is provided with a hot-press forming mechanism for hot-pressing metal substrates. The hot-press forming mechanism include...

Embodiment 2

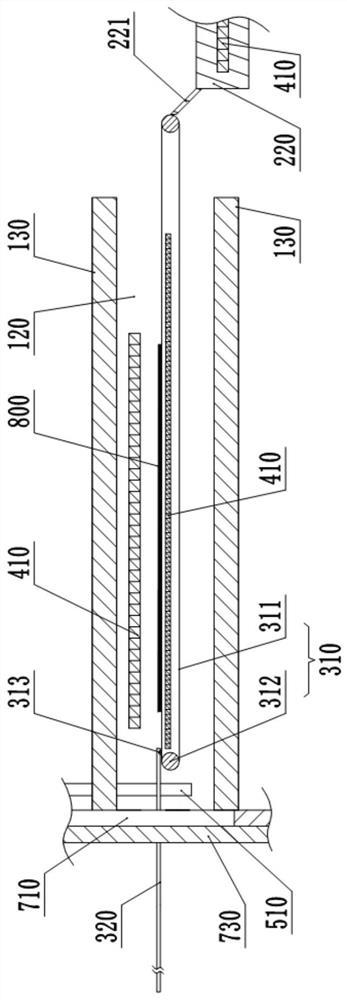

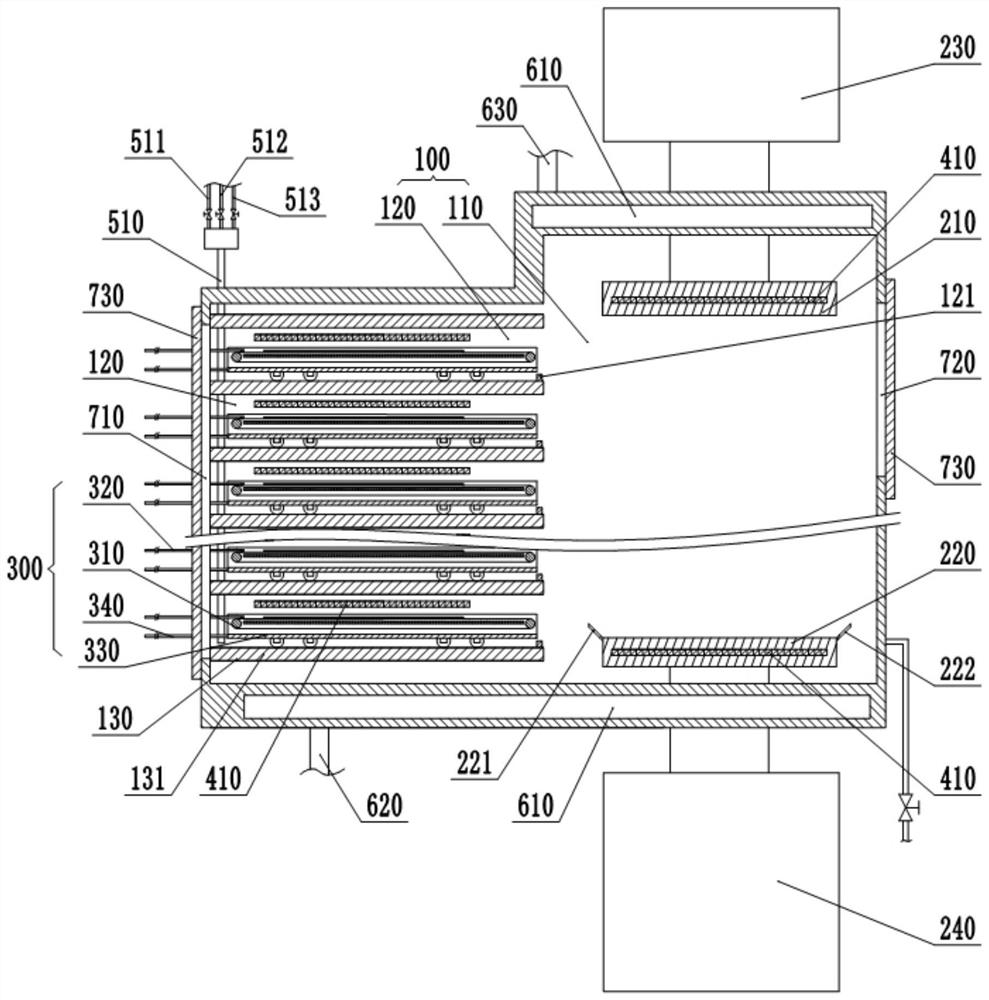

[0063] The only difference between this embodiment and embodiment 1 is: as image 3 , Figure 4 and Figure 5As shown, in this embodiment, the transfer mechanism 300 also includes a horizontally movable transfer body 330 and a drive assembly 2 for driving the transfer body 330, the roller 312 in the transfer assembly 310 is rotatably mounted on the transfer body 330, and the transfer body The bottom end of 330 is provided with several rollers 331 so that the transfer body 330 can easily move horizontally under the action of external force. The heating assembly 410 in the heating system 2 is fixedly installed on the transfer body 330, and the heating assembly 410 in the heating system 2 is located below the conveyor belt 311, so that the heating assembly 410 in the heating system 2 heats the metal foil on the conveyor belt 311 at a close distance 800. The drive assembly 2 includes a push rod 340 arranged horizontally. The right end of the push rod 340 is welded to the transf...

Embodiment 3

[0067] The only difference between this embodiment and embodiment 2 is: as Figure 6 As shown, in this embodiment, the driving assembly includes a horizontally arranged driving rod 320, the end of the roller 312 is coaxially fixedly connected with a gear 314, the driving rod 320 is provided with a rack portion meshed with the gear 314, and the driving rod 320 The left end of 320 protrudes from the integrated chamber 100 , and the driving rod 320 is movably and sealedly connected with the side wall of the integrated chamber 100 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com