Air turbine rocket stamping combined propulsion system

An air turbine and propulsion system technology, applied in the field of aerospace propulsion systems, can solve the problems of restricting flight mission closure, difficult engine matching, insufficient thrust, etc., and achieve the effects of widening the working flight Mach number, increasing the working range, and solving the insufficient thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

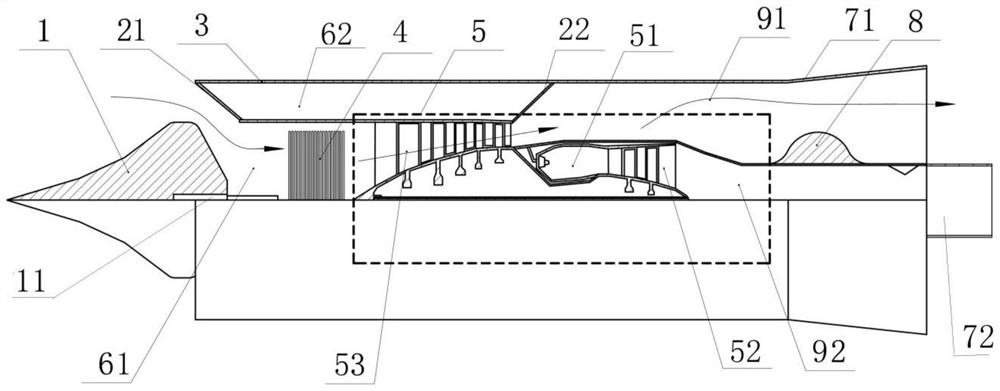

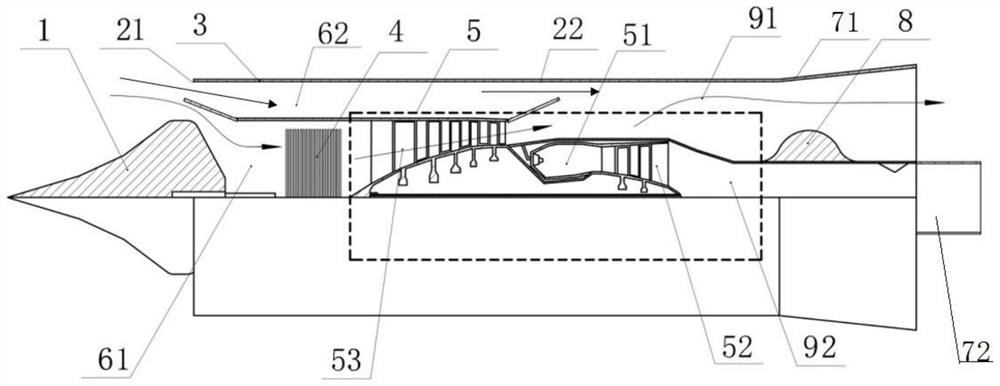

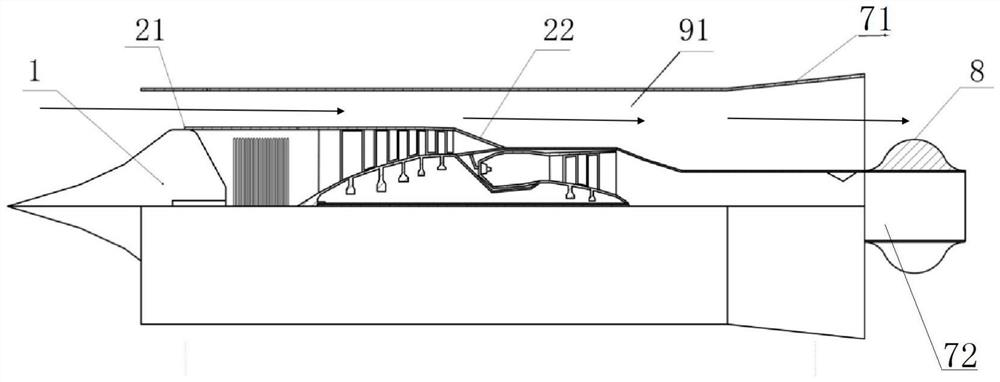

[0046] Embodiment 1: an air turbine rocket ramjet combined propulsion system, comprising a core machine 5 of an air turbine rocket engine, and the core machine 5 includes a coaxially arranged rocket gas generator 51, a turbine 52 and a compressor 53;

[0047] The core machine 5 is arranged in the central flow channel 61 of the air turbine rocket, the core machine 5 is provided with a casing 3 on the periphery, and a stamping isolation section flow channel 62 is arranged in the casing 3, and the stamping isolation section flows. The front end of the channel 62 is provided with a first mode conversion valve 21 corresponding to the inlet of the central flow channel 61, and the end of the flow channel 62 in the stamping isolation section is provided with a second mode conversion valve 22 corresponding to the outlet of the compressor 53; The rocket gas generator 51 is arranged behind the compressor 53, and the periphery of the rocket gas generator 51 is provided with a first combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com