Hydraulic circuit including hydraulic pressure reduction energy recovery

A hydraulic circuit and hydraulic fluid technology, which is applied in the field of hydraulic circuits including hydraulic decompression energy recovery, can solve problems such as wasting energy and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

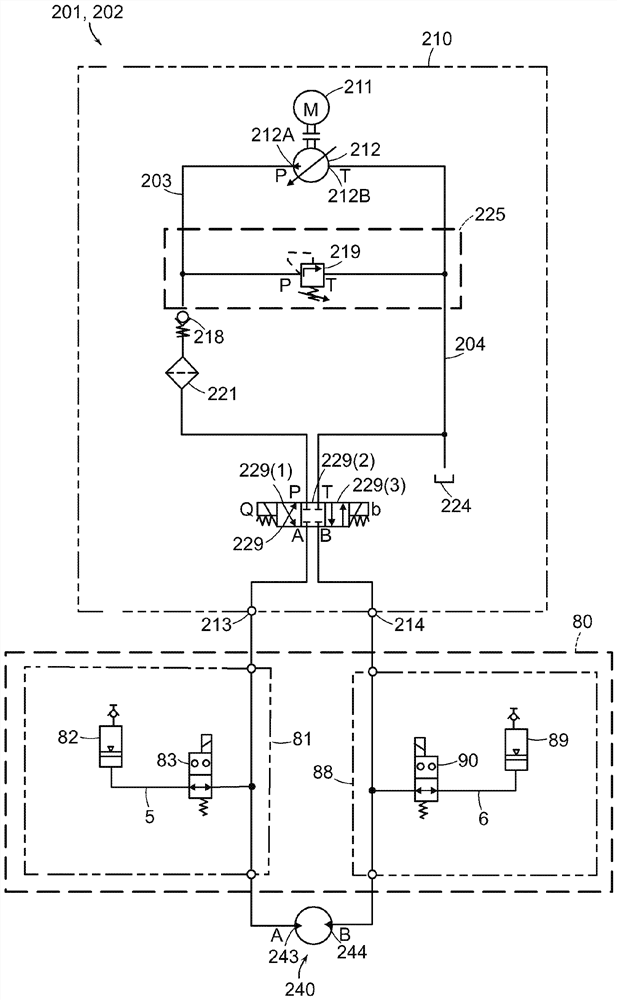

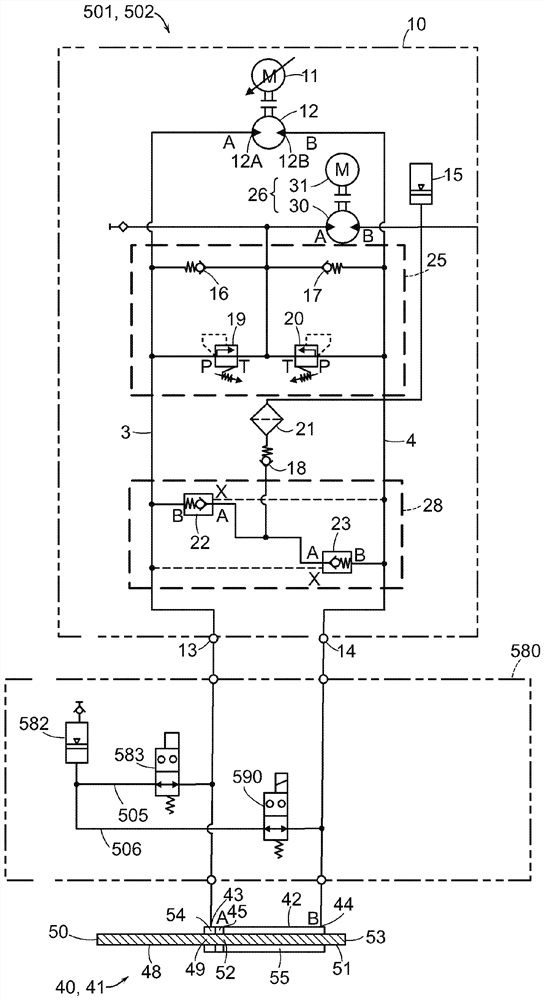

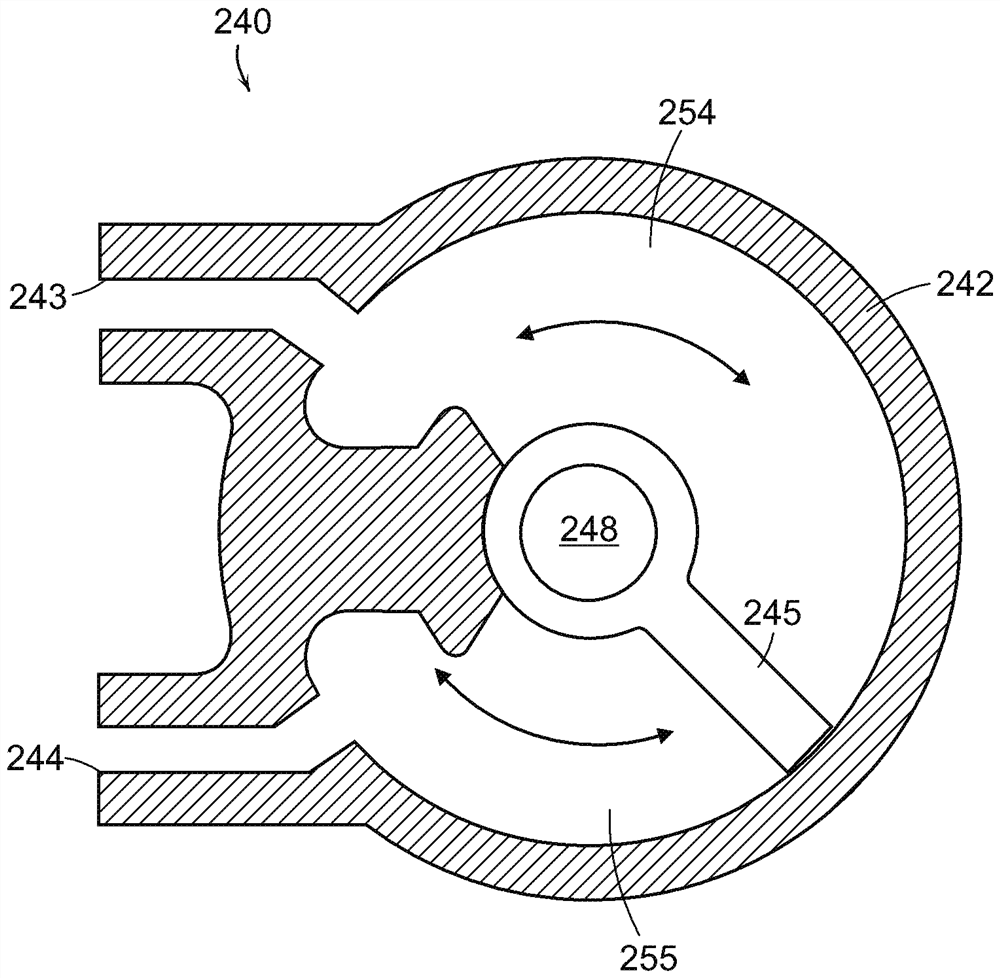

[0042] refer to figure 1 , The oscillating hydraulic system 1 includes a hydraulic circuit 2 . The hydraulic circuit 2 includes an actuator 40 that performs work and a prime mover 10 that controls the flow of hydraulic fluid to the actuator 40 . As used herein, the term "hydraulic fluid" refers to the fluid within the hydraulic circuit 2 . In the illustrated embodiment, the hydraulic fluid is oil, but is not limited thereto. The hydraulic circuit 2 also includes a recovery device 80 disposed between the prime mover 10 and the actuator 40 in the hydraulic circuit 2 . The recovery device 80 allows the oscillating hydraulic system 1 to avoid hydraulic locking by allowing the high pressure side of the actuator to decompress immediately before the actuation direction is reversed. Additionally, recovery device 80 allows the hydraulic system to capture (recover) decompression energy for subsequent use by the hydraulic system, as discussed in detail below.

[0043] Prime mover 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com