Online hydrogen conductivity meter hydrogen exchange column additional error test system and method

A technology of hydrogen conductivity and additional error is applied in the field of additional error inspection system of on-line hydrogen conductivity meter hydrogen exchange column, which can solve the problem of inability to timely and effectively monitor the deterioration of water vapor quality, unqualified additional error of hydrogen exchange column, and hidden dangers of generator set safety. To ensure the accuracy of measurement, improve measurement efficiency, and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

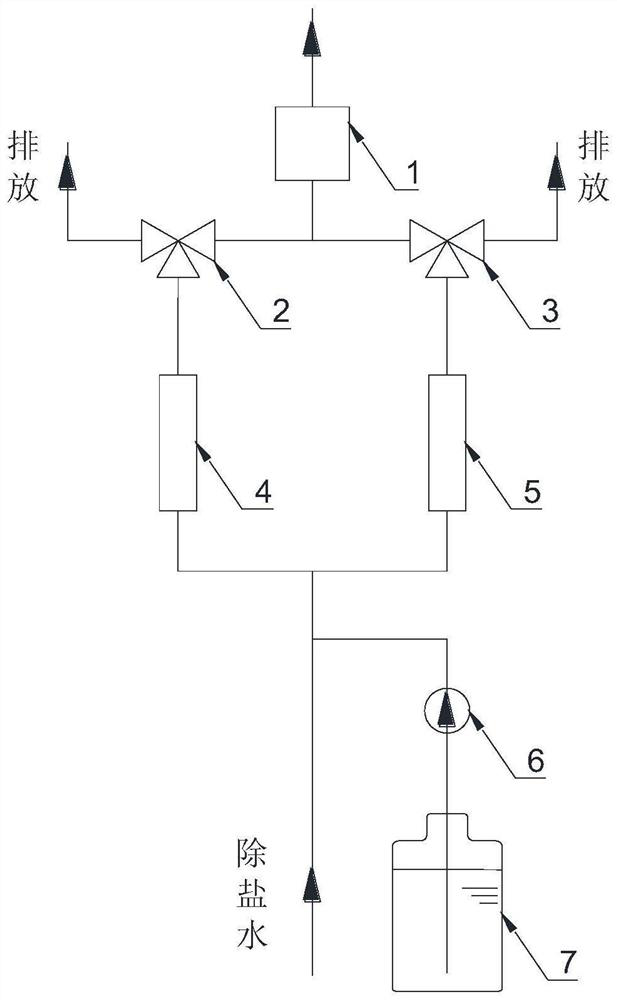

[0054] The following is a detailed description of an online hydrogen conductivity meter hydrogen exchange column additional error checking method provided by the present invention, including the following steps:

[0055] Step 1, with a certain concentration of ammonium chloride (NH 4 C1) solution is perfused in the standard solution bottle 5.

[0056] Step 2. Turn the first three-way valve 2 tangentially to the standard conductivity meter 1, and the second three-way valve 3 tangentially to discharge. Start and adjust the adjustable micropump 4 and adjust the power of the pump so that the indicated value of the standard conductivity meter 1 is around 0.30 μS / cm. After the indicated value of the standard conductivity meter 1 is stable, record the indicated value κ of the standard conductivity meter 1 b1 , to keep the power of the adjustable micropump 4 .

[0057] Step 3, tangentially discharge the first three-way valve 2, and tangentially discharge the second three-way valve 3...

Embodiment 2

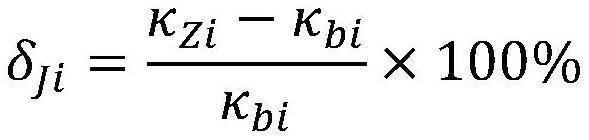

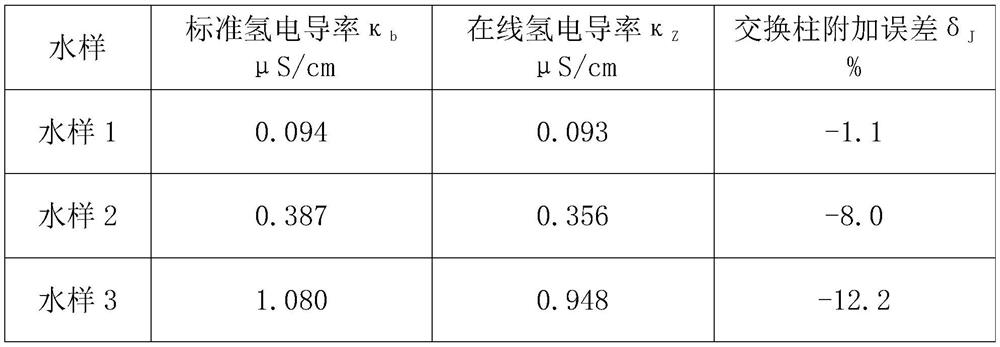

[0070] Taking the hydrogen exchange column of the main steam hydrogen conductivity meter of a power plant as an example, the test results of this test method are shown in Table 4.

[0071] Table 4 Additional error of main steam hydrogen conductivity table hydrogen exchange column

[0072]

[0073] It can be seen from the test results that with the increase of the hydrogen conductivity of the water sample, the absolute value of the additional error of the exchange column is not a fixed value, but increases with the increase of the hydrogen conductivity. Use a water sample with a hydrogen conductivity of 0.064μS / cm for inspection, and the additional error δ of the hydrogen exchange column in the online hydrogen conductivity meter J It is qualified, and the water samples with hydrogen conductivity of 0.100μS / cm, 0.303μS / cm, 0.405μS / cm and 0.657μS / cm are tested, and the online hydrogen conductivity meter hydrogen exchange column has an additional error δ J are unqualified. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com