Small metal magnetic memory crack detection method

A metal magnetic memory and crack detection technology, applied in the direction of material magnetic variables, etc., can solve the problems that the influence of the background magnetic field cannot be eliminated, and the detection result has a large deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

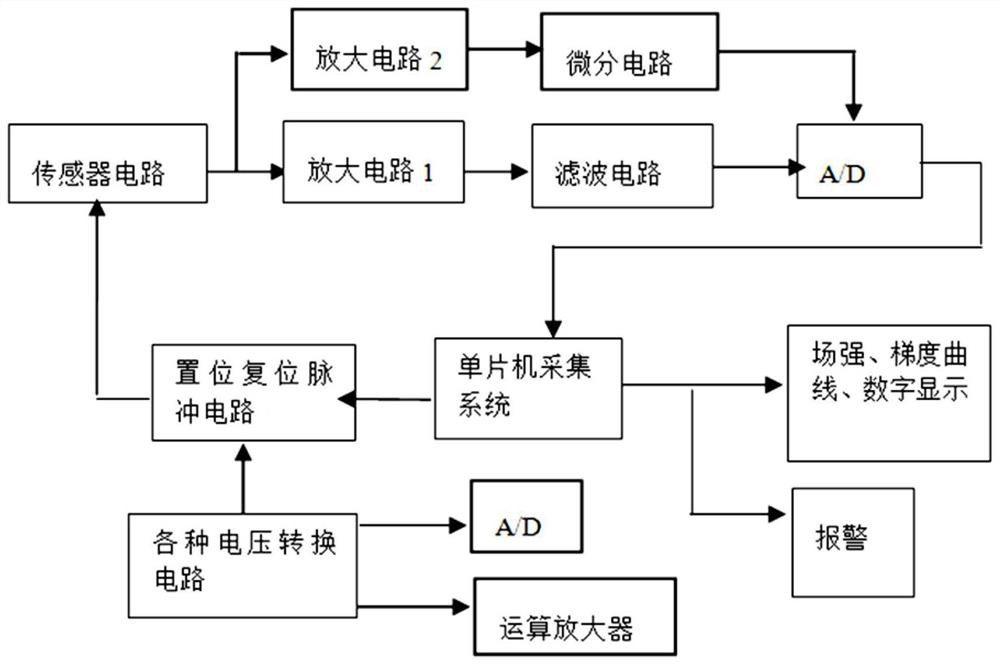

[0027] Such as figure 1 As shown, the detection device used in the present invention includes a single-chip microcomputer, a sensor, an amplifier circuit, a differential circuit, a data processing module, a reset circuit, and a display module.

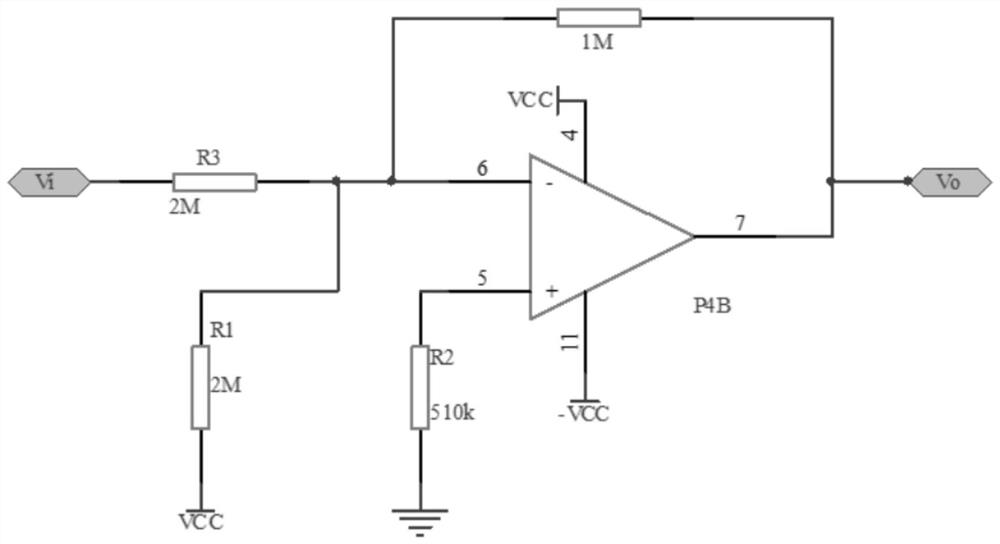

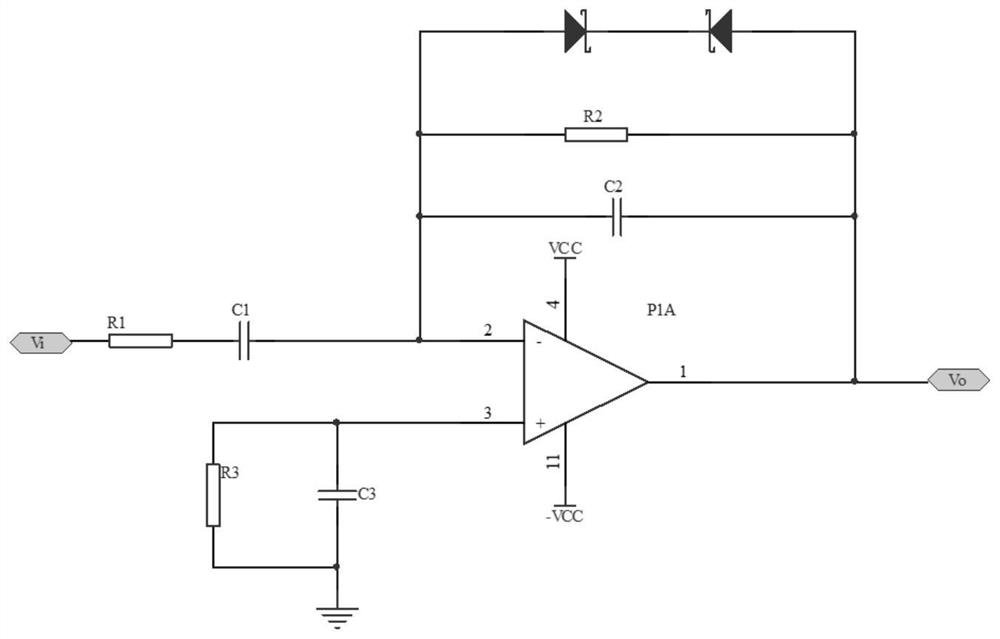

[0028] The sensor is preferably a 4-terminal bridge anisotropic magnetoresistive sensor HMC1021Z. It is a 4-terminal bridge anisotropic magnetoresistive sensor. These magnetoresistive sensors are configured as a 4-element Wheatstone bridge, which converts a magnetic field into a differential output voltage capable of sensing magnetic fields as low as 30μGauss. The typical sensitivity of the sensor is 1mV / V / Gauss, and the resolution is 85μGauss. It is a single-axis sensor in an 8-pin SIP package with a pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com