Core-shell Ni/Co alloy and nitrogen-doped carbon-based wave-absorbing composite material and preparation method thereof

A technology of nitrogen-doped carbon and composite materials, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problems of narrow effective absorption bandwidth, complicated synthesis steps, and unfriendly environment, so as to improve the absorption performance and optimize the impedance Matching, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

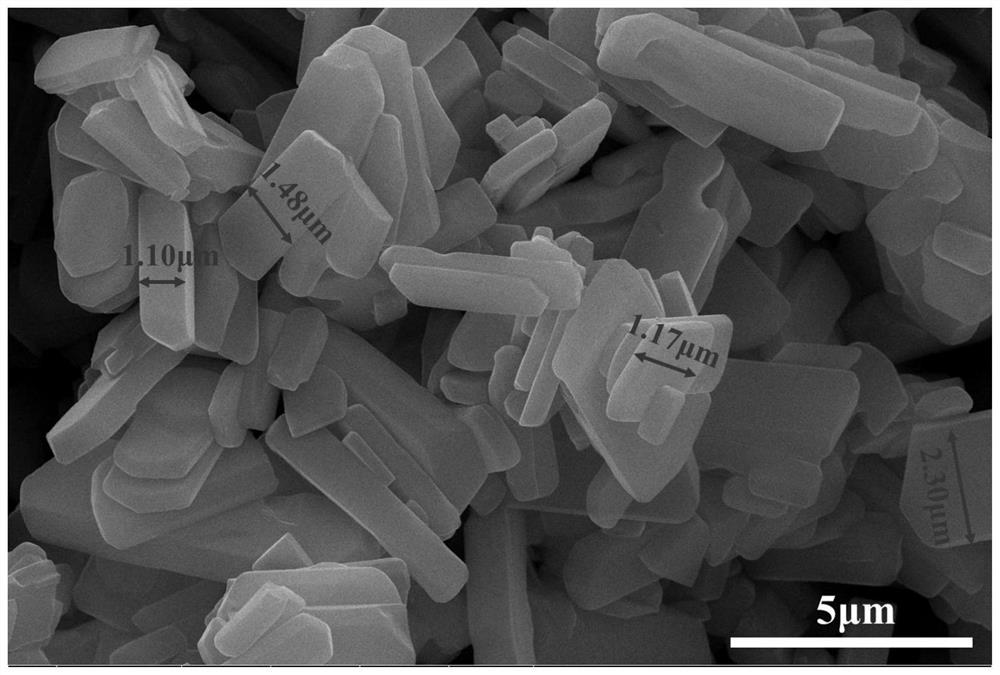

[0031] (1) Preparation of Co / Ni-MOF precursor

[0032] 1.21g CH 3 COONa·3H 2 O and 1.22g of nicotinic acid were dissolved in 100ml of deionized water and stirred for 30 minutes to obtain A solution. At the same time, 2.1gNi(NO 3 ) 2 ·6H 2 O, 1.2gCo(NO 3 ) 2 ·6H 2 O and 1.1 g of polyvinylpyrrolidone (PVP) were dissolved in 100 ml of deionized water, and stirred for 30 minutes to obtain solution B. Solution B was slowly added to solution A and stirred for 30 minutes. Then the uniformly stirred mixed solution was transferred to a 250 ml polytetrafluoroethylene stainless steel autoclave, and reacted at 120° C. for 6 hours. After natural cooling to room temperature, a gray-blue precipitate was obtained, which was washed three times with deionized water, and vacuum-dried at 60 °C for 24 hours to obtain the CoNi-MOF precursor.

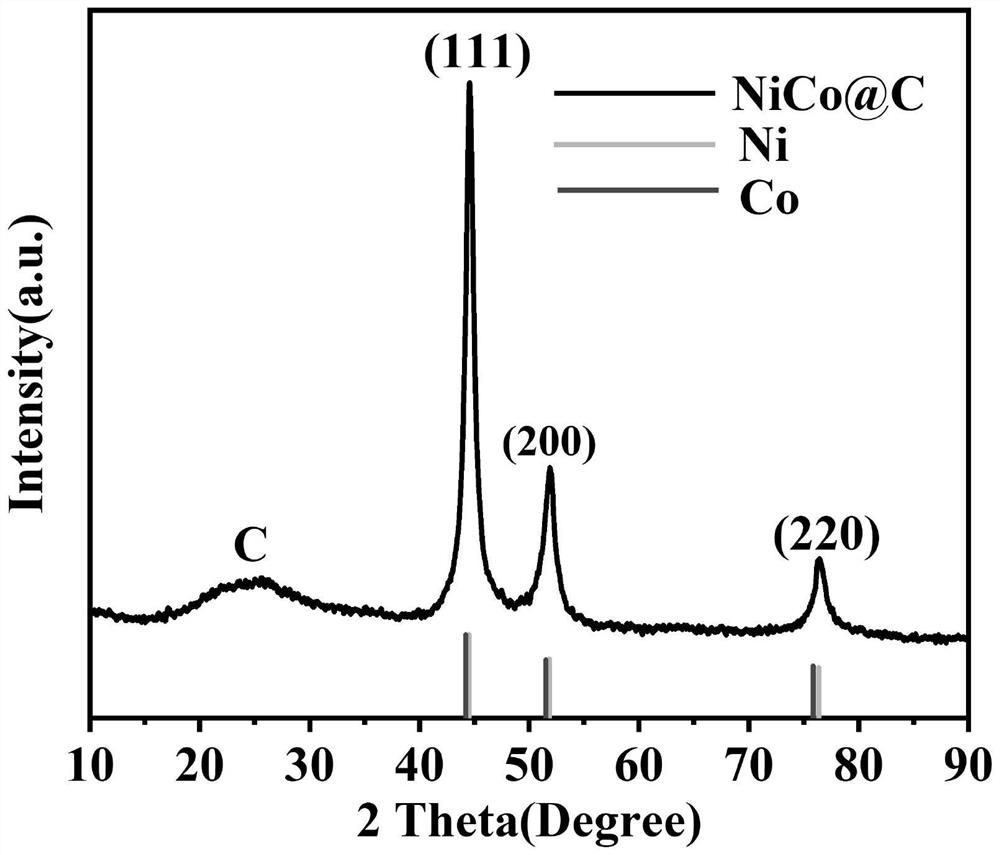

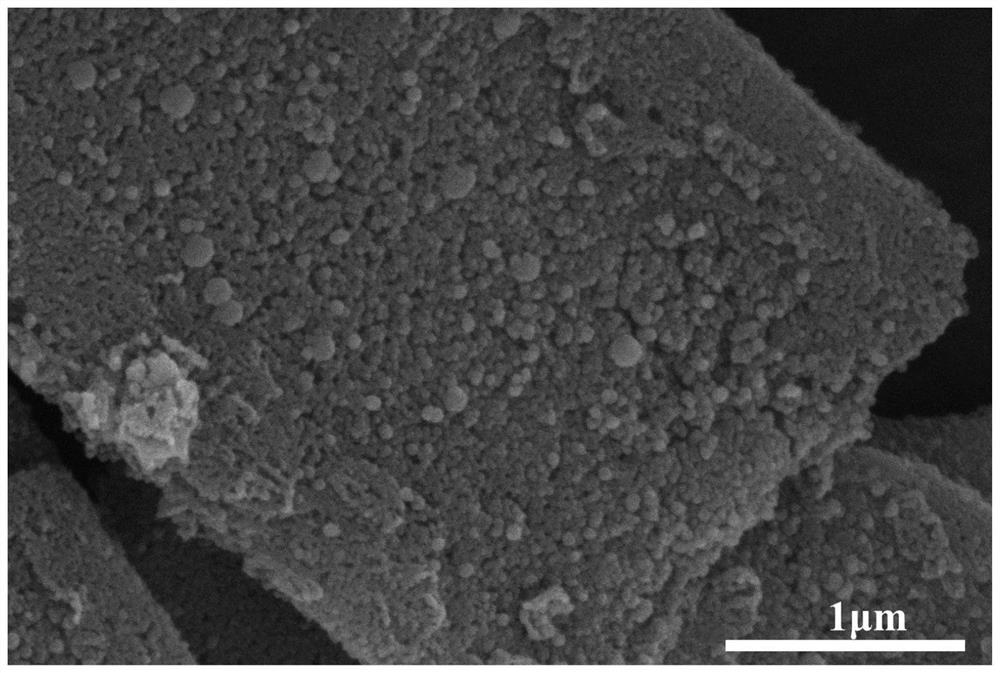

[0033] (2) Preparation of Ni / Co alloy@nitrogen-doped carbon-based microwave-absorbing composite material

[0034] The Ni / Co-MOF precursor is place...

Embodiment 2

[0042] (1) Preparation of Co / Ni-MOF precursor

[0043] CH 3 COONa·3H 2 O is 2.42g, niacin is 2.44g, Ni(NO 3 ) 2 ·6H 2 O is 3.15g, Co(NO 3 ) 2 ·6H 2 Og is 2.4, and other is with embodiment 1.

[0044] (2) Preparation of core-shell Ni / Co alloy@nitrogen-doped carbon-based microwave-absorbing composite

[0045]The Ni / Co-MOF precursor was placed in a crucible, pyrolyzed at 600 °C for 2 hours in an argon atmosphere, and the heating rate was 2 °C / min, and then naturally cooled to obtain a Ni / Co alloy with a core-shell structure@nitrogen-doped Heterocarbon-based microwave-absorbing composite (Ni / Co@C-600).

[0046] (3) Ni / Co@C-600 absorbing performance test

[0047] The absorbing material used is the composite material prepared in Example 2. Others are the same as in Example 1. When the absorbing material is measured at a frequency of 8.9GHz and a thickness of 3.5mm, the optimal RL value can reach -71.9dB, RL The effective absorbing bandwidth of <-10 is up to 16GHz, coverin...

Embodiment 3

[0049] (1) Preparation of CoNi-MOF precursor

[0050] CH 3 COONa·3H 2 O is 3.63g, niacin is 3.66g, Ni(NO 3 ) 2 ·6H 2 O is 4.2g, Co(NO 3 ) 2 ·6H 2 Og is 3.6, and other is with embodiment 1.

[0051] (2) Preparation of Ni / Co alloy@nitrogen-doped carbon-based microwave-absorbing composite material

[0052] The Ni / Co-MOF precursor is placed in a crucible, pyrolyzed at 650°C for 2 hours in an argon atmosphere, and the heating rate is 2°C / min, and then naturally cooled to obtain Ni / Co alloy@nitrogen-doped carbon-based absorber Composite material (Ni / Co@C-650).

[0053] (3) Ni / Co@C-650 absorbing performance test

[0054] The wave-absorbing material used is the composite material prepared in Example 3. Others are the same as in Example 1. When the frequency of the wave-absorbing material is 16.4GHz and the thickness is 2mm, the optimal RL value can reach -66.3dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com