Mushroom-like pileus-shaped wave-absorbing material and preparation method thereof

A wave absorbing material and mushroom technology, applied in the field of wave absorbing agents, can solve the problems of poor impedance matching performance and efficient attenuation of electromagnetic waves, and achieve the effects of excellent wave absorbing performance, strong reflection loss ability and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the mushroom-like cap-shaped wave-absorbing material provided by the application, the steps are as follows:

[0041] Step 1, configuring an aqueous alcohol solution with a pH of 8 to 10;

[0042] Step 2, add tetraethyl orthosilicate, resorcinol and formaldehyde in sequence to the above alcohol aqueous solution as required to obtain a reaction solution, and the interval between additions is 10 to 20 minutes; the alcohols used include methanol, ethanol and acrylic acid. Saturated monohydric alcohol of alcohol; the volume ratio of alcohol aqueous solution water to alcohol is 1:4~8; the molar ratio of tetraethyl orthosilicate, resorcinol and formaldehyde is (3~7):1:(5~8 );

[0043] Step 3, subjecting the above reaction solution to hydrothermal reaction, washing and drying the obtained product; specifically, reacting at 100-120°C for 8-16 hours;

[0044] Step 4, the obtained product is etched with an acidic solution, washed and dried to obtain pre...

Embodiment 1

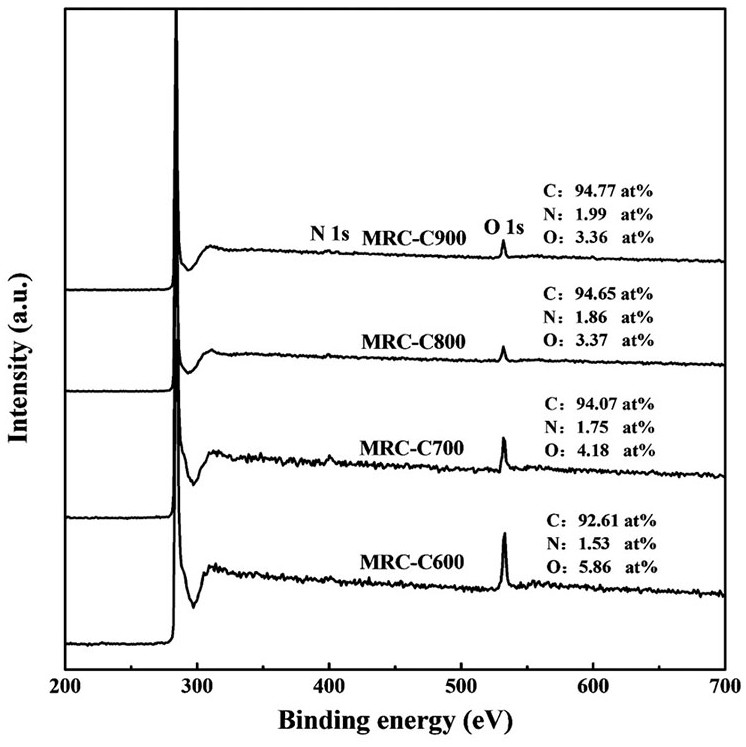

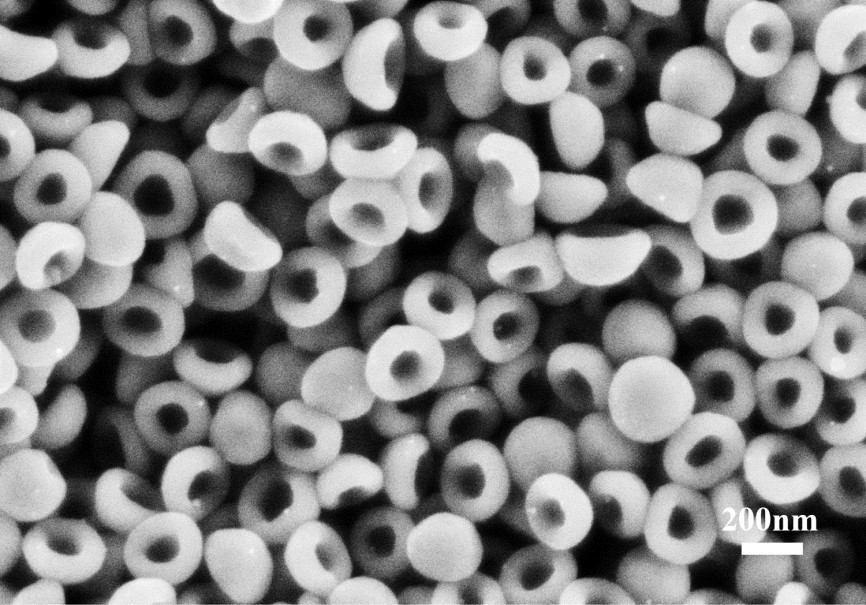

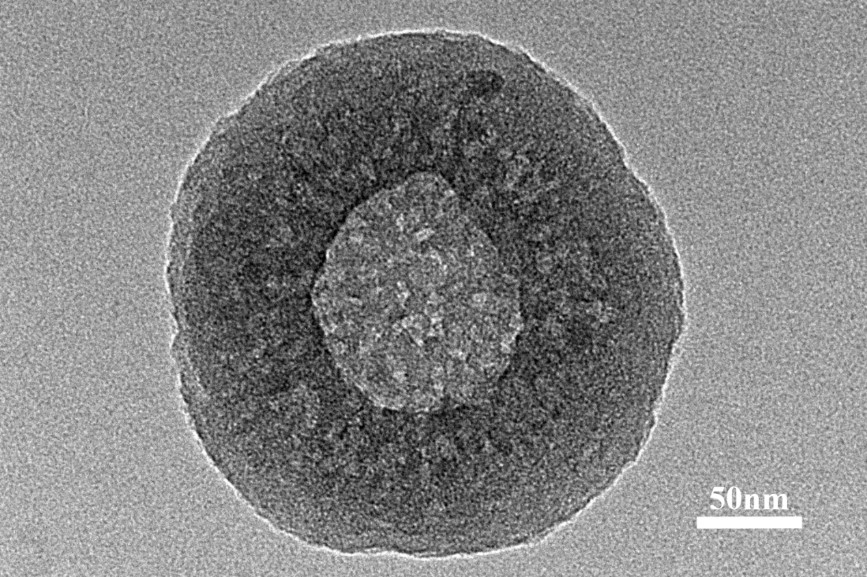

[0046]Example 1: under stirring conditions, add 83mmol of ammonia water to 80ml of alcohol-water mixed solution; under the condition of constant temperature stirring at 30°C, add 16mmol of tetraethyl orthosilicate and 5mmol of resorcinol to the above mixed solution in sequence And 30mmol of formaldehyde, the addition time is 10min, in order to mix evenly, and stir for 12h to get the reaction solution; the reaction solution is hydrothermally reacted at 100°C for 12h, and the reaction product is centrifugally washed and placed in a constant temperature blast drying oven at 60°C Dry for 8 hours; place the dried product in a hydrofluoric acid solution with a mass fraction of 10% for etching treatment for 4 hours at 25°C, wash the product by centrifugation, and dry it in a constant temperature blast drying oven at 50°C 10h; After grinding the obtained product evenly, place it in a nitrogen atmosphere, raise the temperature up to 600°C at a rate of 5°C / min, and keep it warm for 4h to...

Embodiment 2

[0047] Example 2: under stirring conditions, add 83mmol of ammonia water to 80ml of alcohol-water mixed solution; under the condition of constant temperature stirring at 30°C, add 20mmol of tetraethyl orthosilicate and 6mmol of resorcinol to the above mixed solution in sequence And 35mmol of formaldehyde, adding interval time is 10min, in order to mix evenly, stir for 12h to get the reaction liquid; react the reaction liquid at 100°C for 12h, the reaction product is centrifugally washed and placed in a constant temperature blast drying oven at 60°C Dry for 8 hours; place the dried product in a hydrofluoric acid solution with a mass fraction of 10% for etching treatment for 4 hours at 25°C, wash the product by centrifugation, and dry it in a constant temperature blast drying oven at 50°C 10h; After grinding the obtained product evenly, place it in a nitrogen atmosphere, raise the temperature to 700°C at a rate of 5°C / min, and keep it warm for 4h to obtain a mushroom-like cap-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com