Skull repair polyether-ether-ketone material and preparation method thereof

A technology of polyether ether ketone and skull, which is applied in the direction of pharmaceutical formulations, prostheses, coatings, etc., can solve problems such as potential safety hazards and the process of surface modification of PEEK materials, and achieve the effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

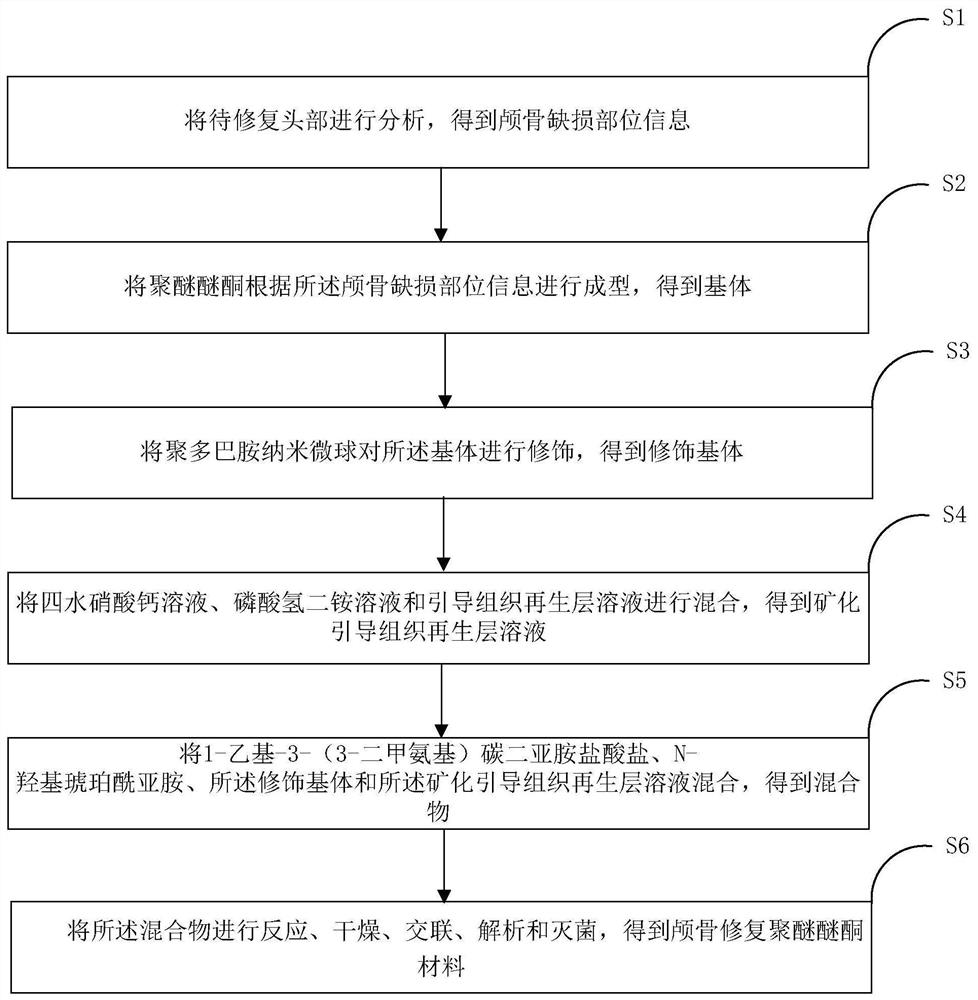

[0039]According to a typical embodiment of the present invention, a preparation method of a polyetheretherketone material for skull repair is provided, the method comprising:

[0040] S1. Analyze the head to be repaired to obtain information on the skull defect;

[0041] S2. Polyetheretherketone is molded according to the information on the skull defect to obtain a matrix;

[0042] In some embodiments, the matrix can be made of polyether ether ketone two-dimensional braided material or made of polyether ether ketone material by 3D printing. The following description is only based on the preparation of the matrix by 3D printing:

[0043] First, perform CT plain and enhanced scans of the skull defect site, and then perform 3D reconstruction to determine the location, size, and shape of the skull defect; then import the scan data into the software to design the bone defect model, save it in STL format, and import it into a 3D printer. The software was used to correct and calibra...

Embodiment 1

[0076] A preparation method of a cranial bone repair polyetheretherketone material, the steps are as follows:

[0077] Obtain or make a polyetheretherketone material. Obtain polyetheretherketone two-dimensional braided material or obtain polyetheretherketone material by 3D printing. The method of 3D printing to prepare the polyetheretherketone material is as follows: first, the CT plain and enhanced scan of the skull defect site is performed, and then three-dimensional reconstruction is performed to determine the position, size, shape, etc. of the skull defect; then the scan data is poured into the software for bone defects Model design, save in STL format and import into 3D printer, use software to correct and calibrate the skull defect model, use digital equipment to shape according to the data of the model, and produce polyetheretherketone matching the defect site. The polyetheretherketone raw material meets the standard of YY / T 0660-2008 "Standard Specification for Polyet...

Embodiment 2

[0085] A preparation method of a cranial bone repair polyetheretherketone material, the steps are as follows:

[0086] Obtain or make a polyetheretherketone material. Obtain polyetheretherketone two-dimensional braided material or obtain polyetheretherketone material by 3D printing. The method of 3D printing to prepare the polyetheretherketone material is as follows: first, the CT plain and enhanced scan of the skull defect site is performed, and then three-dimensional reconstruction is performed to determine the position, size, shape, etc. of the skull defect; then the scan data is poured into the software for bone defects Model design, save in STL format and import into 3D printer, use software to correct and calibrate the skull defect model, use digital equipment to shape according to the data of the model, and produce polyetheretherketone matching the defect site. The polyetheretherketone raw material meets the standard of YY / T 0660-2008 "Standard Specification for Polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com