Straw granulator

A granulator and straw technology, applied in the direction of presses, manufacturing tools, material forming presses, etc., can solve the problems of inability to protect materials, large drop, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

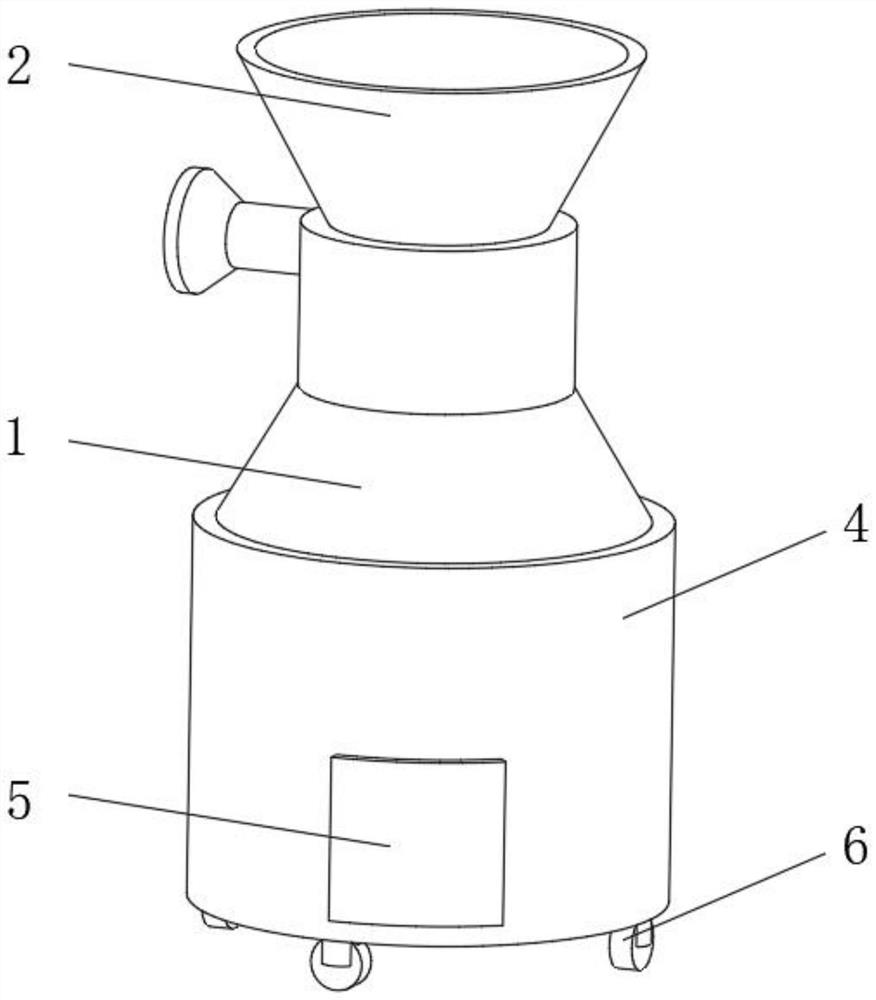

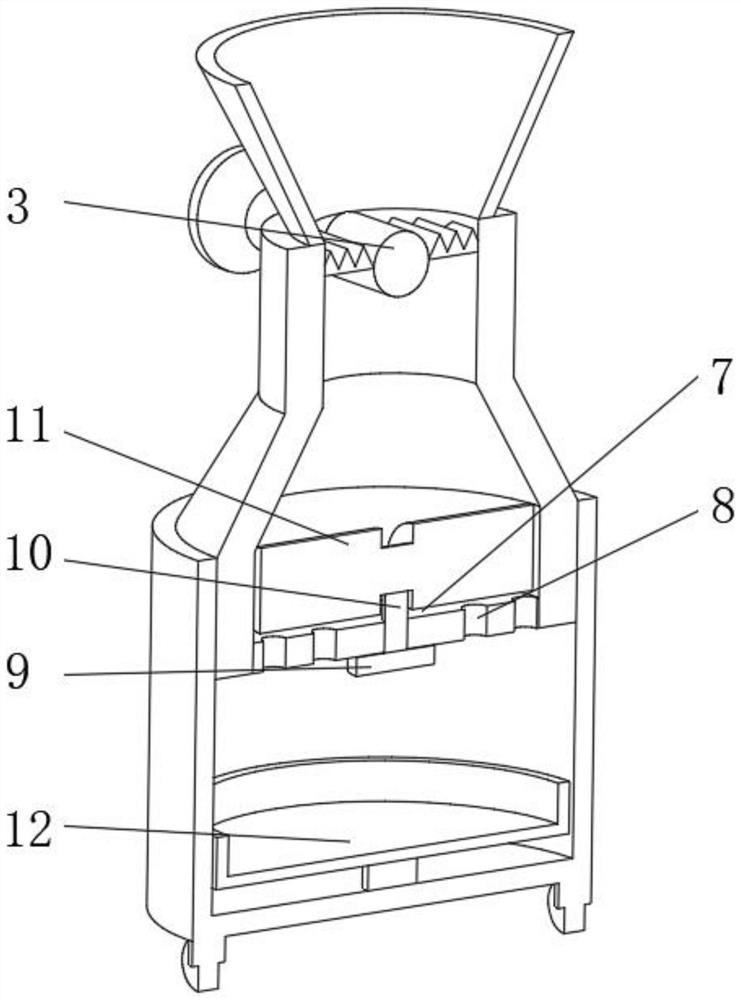

[0028] see Figure 1-4 , the present invention provides a technical solution: a straw granulator, including a shell 1, the top of the shell 1 is connected with a feed frame 2, the inner wall of the shell 1 is fixedly connected with an adjustment mechanism 3 near the position of the feed frame 2, the shell The bottom of 1 is connected with a bottom frame 4, and the outer side of the bottom frame 4 is provided with a material intake 5, and the side of the bottom frame 4 far away from the shell 1 is uniformly equipped with a rolling wheel 6, and the inner wall of the shell 1 is equipped with an extruding plate 7, extruding The surface of the plate 7 is uniformly provided with an extrusion discharge hole 8, and the bottom of the extrusion plate 7 is equipped with a driving motor 9, and the output end of the driving motor 9 is rotatably connected to a rotating rod 10, and the end of the rotating rod 10 away from the driving motor 9 runs through the extrusion The pressing plate 7 is...

Embodiment 2

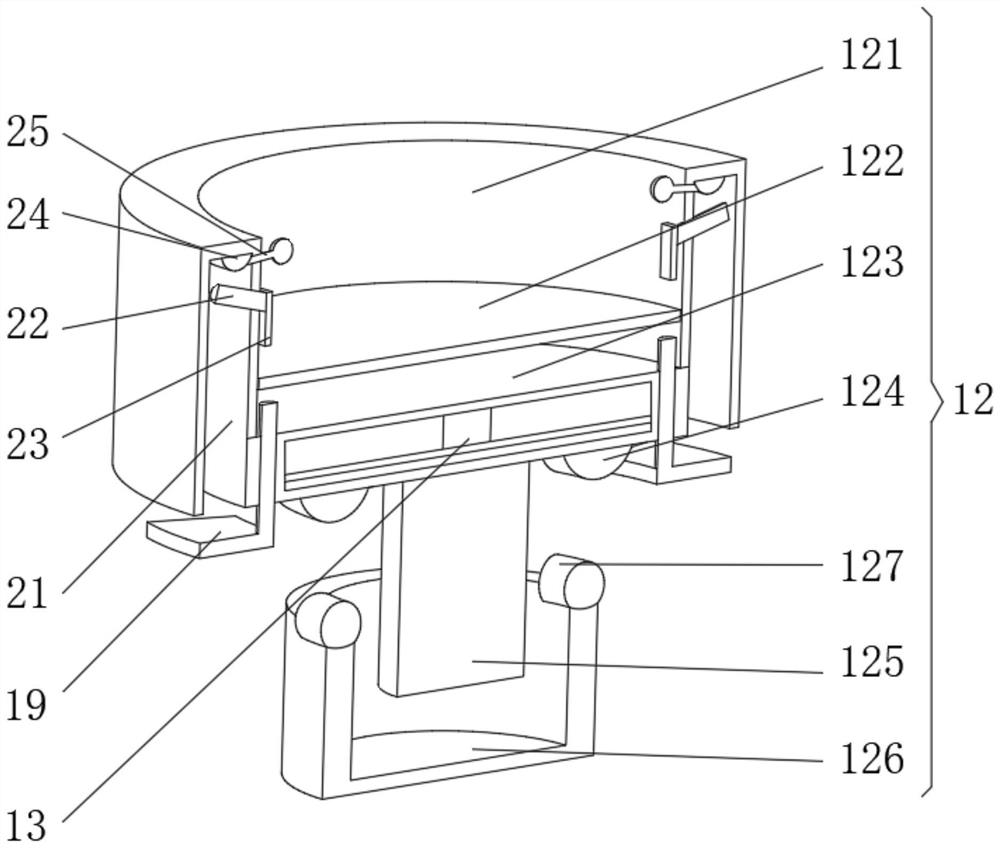

[0035] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a drying device 13 is installed inside the magnetic device 12, and the drying device 13 includes a drying frame 131, and the top of the drying frame 131 is uniformly provided with an arc The hole 132, the bottom of the drying frame 131 is fixedly connected with the inner wall of the hollow plate 123, the inner top of the drying frame 131 is equipped with a piston cylinder 133, the inside of the piston cylinder 133 is slidingly connected with a piston head 134, and one side of the piston head 134 is installed with a The piston rod 135 and the bottom of the inner wall of the drying frame 131 are equipped with a heating wire 136 .

[0036] When in use, turn on the heating wire 136 to heat the air inside the drying frame 131, and when one end of the piston rod 135 is lowered to a certain position by the gravity of the load-bearing plate 122, the piston head 134 slides along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com