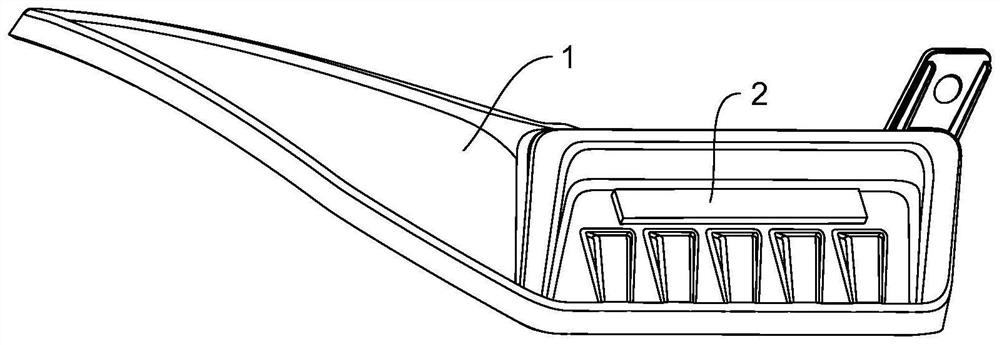

Luminous mudguard

A technology for fenders and luminescent powder, which is applied in luminescent coatings, optical signals, transportation and packaging, etc. It can solve problems such as collisions or secondary accidents, provide warnings, etc., and achieve the effects of improving stability, improving performance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Acrylic resin: 100 parts of acrylic resin

[0047] Active monomer: 10 parts of hydroxyethyl methacrylate, 7.5 parts of tripropylene glycol diacrylate

[0048] Luminescent powder: KH560 modified rare earth doped aluminate luminescent powder 20 parts

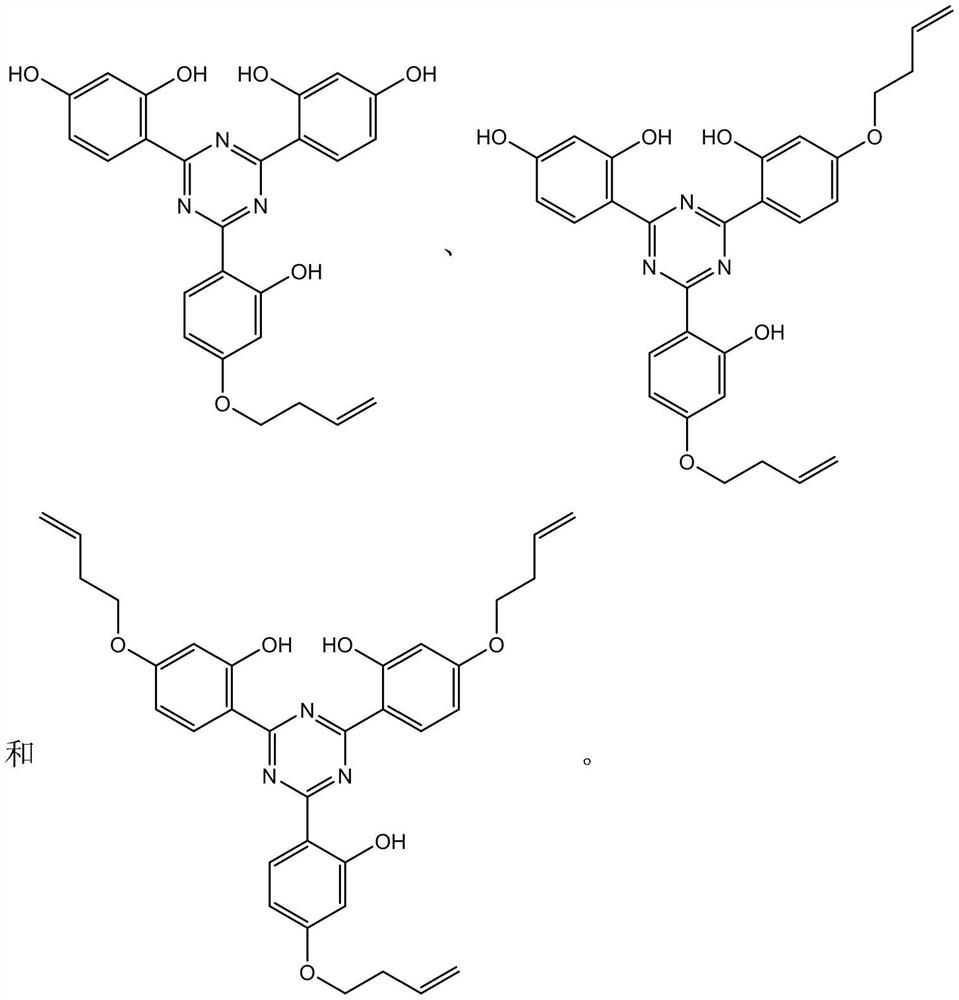

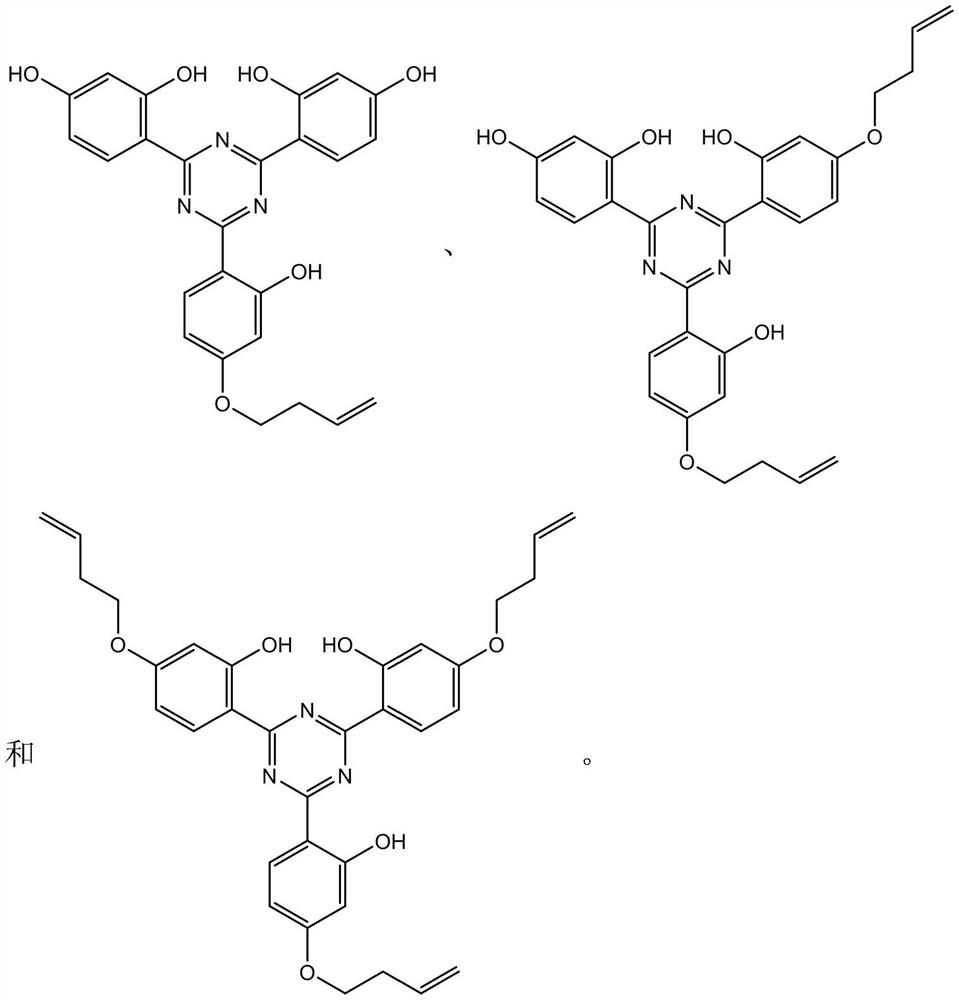

[0049] UV absorber: 5 parts of a mixture of UV absorber I, UV absorber II and UV absorber III

[0050] Thickener: 1.2 parts of acrylic thickener

[0051] Photoinitiator: 6 parts of isopropylthioxanthone

[0052] Water: 22 parts of water.

[0053] Add acrylic resin, active monomer, luminescent powder and water into a mixer and stir evenly, then add it to a ball mill and grind until the particle size of the slurry is less than 50 μm, and then add ultraviolet absorbers, thickeners, and photoinitiators under dark conditions. Stir for 30 min under the condition of rotating speed of 500 r / min, pass through 80 mesh sieve to obtain luminescent coating.

Embodiment 2

[0055] Acrylic resin: 100 parts of epoxy modified acrylic resin

[0056] Active monomer: 10 parts of hydroxyethyl methacrylate, 7.5 parts of tripropylene glycol diacrylate

[0057] Luminescent powder: KH560 modified rare earth doped aluminate luminescent powder 20 parts

[0058] UV absorber: 5 parts of a mixture of UV absorber I, UV absorber II and UV absorber III

[0059] Thickener: 1.2 parts of acrylic thickener

[0060] Photoinitiator: 6 parts of isopropylthioxanthone

[0061] Water: 22 parts of water.

[0062] Add acrylic resin, active monomer, luminescent powder and water into a mixer and stir evenly, then add it to a ball mill and grind until the particle size of the slurry is less than 50 μm, and then add ultraviolet absorbers, thickeners, and photoinitiators under dark conditions. Stir for 30 min under the condition of rotating speed of 500 r / min, pass through 80 mesh sieve to obtain luminescent coating.

Embodiment 3

[0064] Acrylic resin: 100 parts of epoxy modified acrylic resin

[0065] Active monomer: 10 parts of hydroxyethyl methacrylate, 7.5 parts of tripropylene glycol diacrylate

[0066] Luminescent powder: 20 parts of rare earth doped aluminate luminescent powder modified by silane coupling agent (silane coupling agent is KH560 and KH570 with a mass ratio of 5:1)

[0067] UV absorber: 5 parts of a mixture of UV absorber I, UV absorber II and UV absorber III

[0068] Thickener: 1.2 parts of acrylic thickener

[0069] Photoinitiator: 6 parts of isopropylthioxanthone

[0070] Water: 22 parts of water.

[0071] Add acrylic resin, active monomer, luminescent powder and water into a mixer and stir evenly, then add it to a ball mill and grind until the particle size of the slurry is less than 50 μm, and then add ultraviolet absorbers, thickeners, and photoinitiators under dark conditions. Stir for 30 min under the condition of rotating speed of 500 r / min, pass through 80 mesh sieve to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com