Preparation method and application of polyamide acid varnish

A technology of polyamic acid and varnish, applied in the direction of coating, etc., can solve the problems of being unable to withstand high heat, unable to provide long-term stable work, etc., and achieve high PDIV and reduce VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

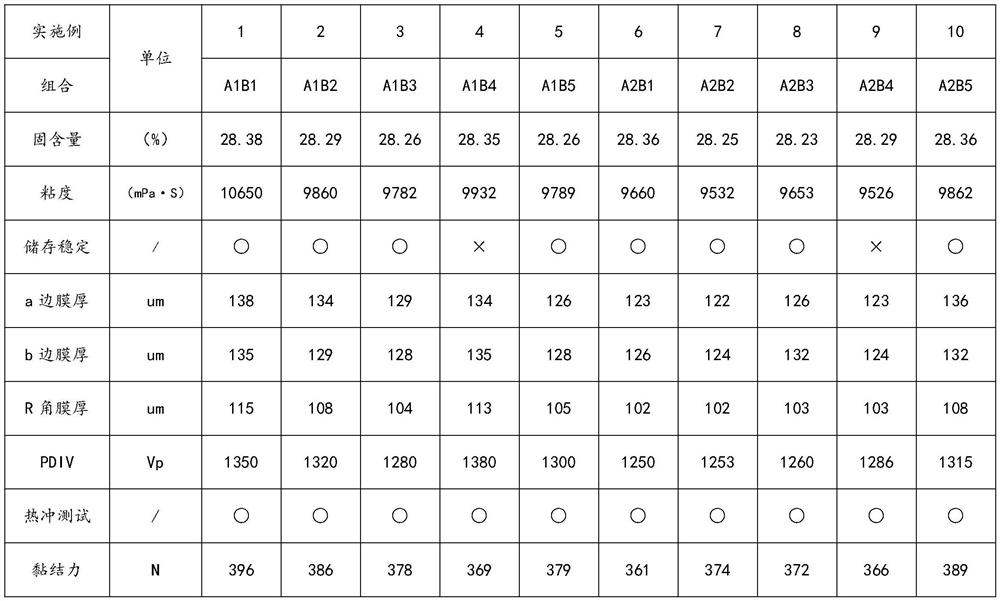

Examples

preparation example Construction

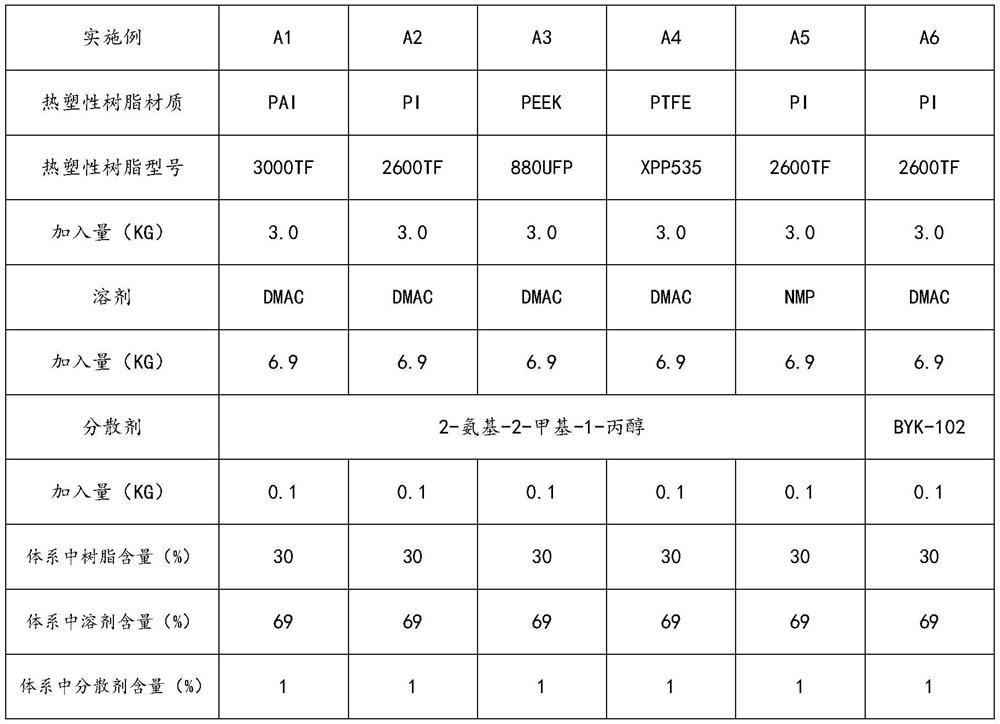

[0036] Preparation of thermoplastic resin powder emulsion

[0037] In Examples A1 to A4, 3kg of thermoplastic resin powder was added to 6.9kg of solvent, and 0.1kg of 2-amino-2-methyl-1-propanol was added, and high-speed grinding was performed for 3 hours to obtain a thermoplastic resin powder emulsion.

Embodiment A5

[0038] Example A5, 3kg of thermoplastic polyimide powder 2600TF was added to 6.9kg of NMP solvent, and 0.1kg of 2-amino-2-methyl-1-propanol was added, and high-speed grinding was performed for 3 hours to obtain thermoplastic resin powder emulsion.

Embodiment A6

[0039] Example A6, 3 kg of thermoplastic polyimide powder 2600TF was added to 6.9 kg of DMAC solvent, and 0.1 kg of DISPERBYK-102 was added, and high-speed grinding was performed for 3 hours to obtain a thermoplastic resin powder emulsion.

[0040] The above embodiment parameters are recorded in the following table 1.

[0041] Table 1

[0042]

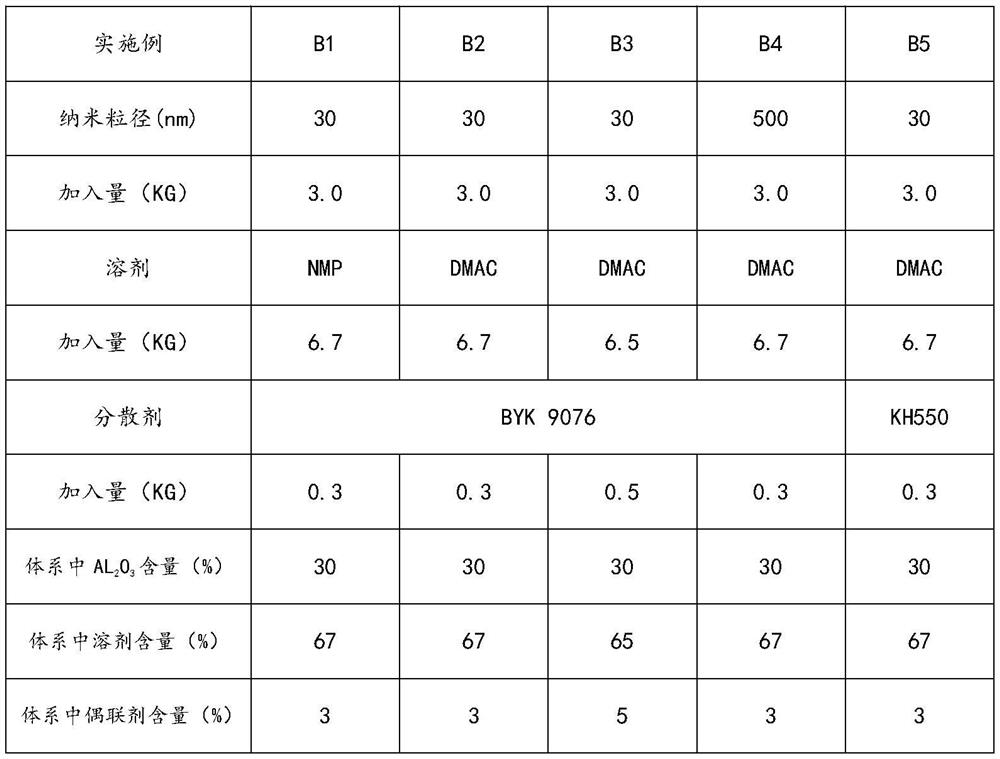

[0043] Preparation of Nano Al2O3 Solution

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com