Casing deformation wireless monitoring system in well cementation, fracturing and production processes

A monitoring system and production process technology, applied in casing, drill pipe, measurement, etc., can solve problems such as the need to optimize convenience, increase the complexity of the system, and improve the accuracy, so as to improve the quality of cementing operations and improve construction. Efficiency, the effect of improving the pulp replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

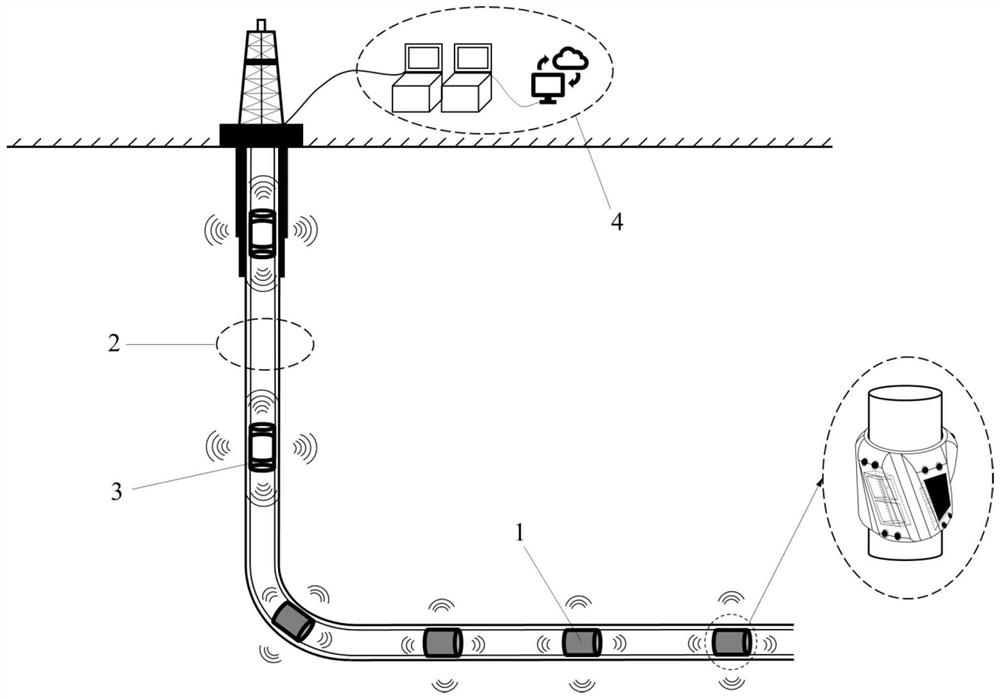

[0066] Such as figure 1 As shown, a wireless monitoring system for casing deformation in cementing, fracturing, and production processes provided by the present invention consists of a downhole casing deformation wireless monitor 1, a transmission channel 2, a signal relay device 3 and a ground receiving system 4. Partial composition.

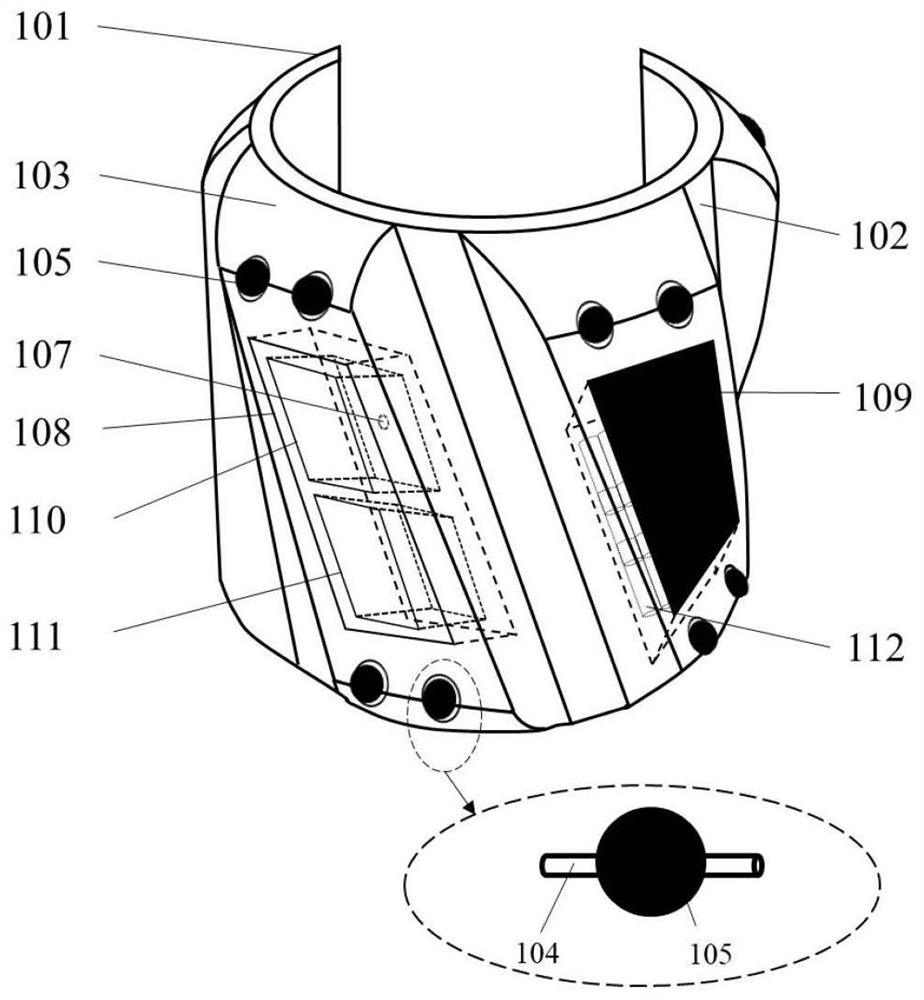

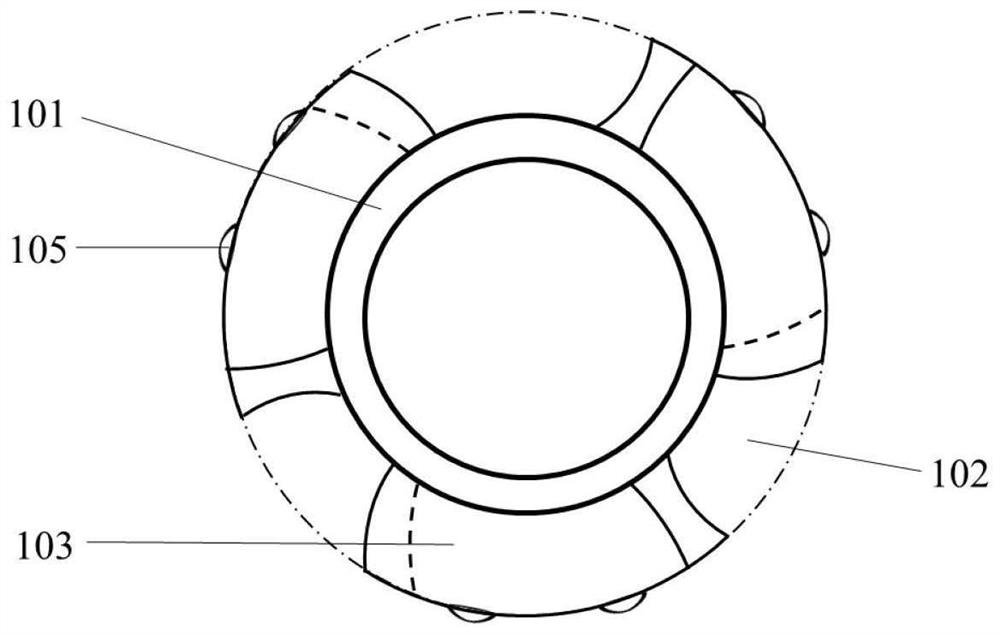

[0067] Such as Figures 2 to 4 As shown, the downhole casing deformation wireless monitor 1 includes: a monitor body 101, a diversion groove 102, a supporting rib 103, a roller 104, a drag reducing roller 105, an annular sensing strain gauge set 106, and a wiring hole 107 , a cavity assembly space 108 , a cover 109 , a signal detection and conversion device 110 , a signal transmitting device 111 and a battery pack 112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com