Garbage can fire monitoring and pretreatment equipment

A pretreatment and trash can technology, applied in trash cans, garbage collection, fire rescue, etc., can solve the problems of trash cans that are prone to fire, unable to monitor and deal with them in the first place, economic losses, etc., to protect social property safety and users Personal safety, low upgrade cost, fire containment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

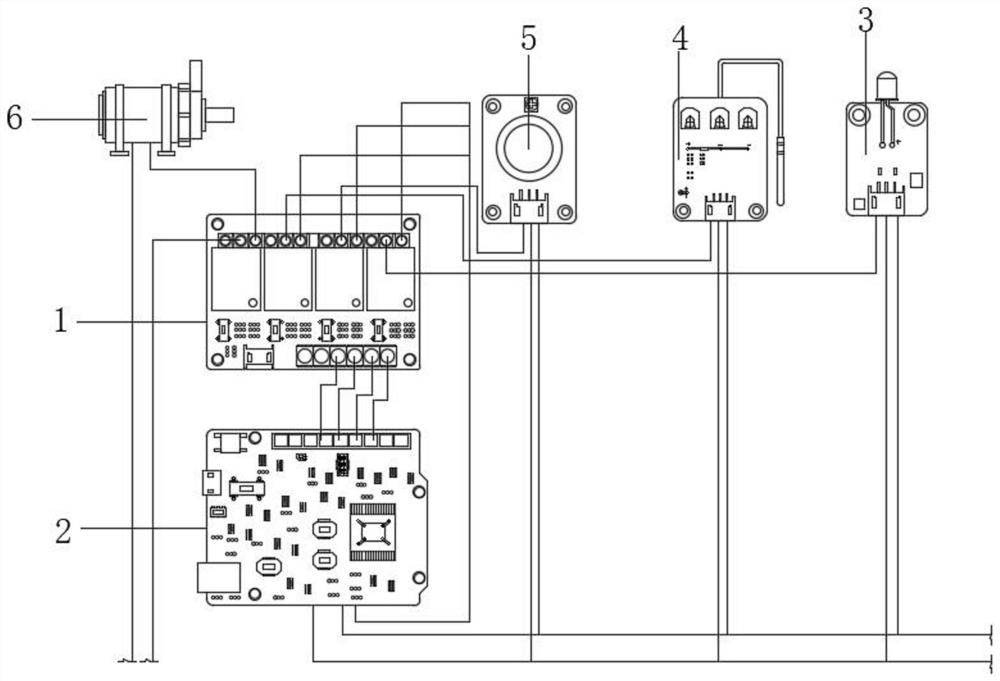

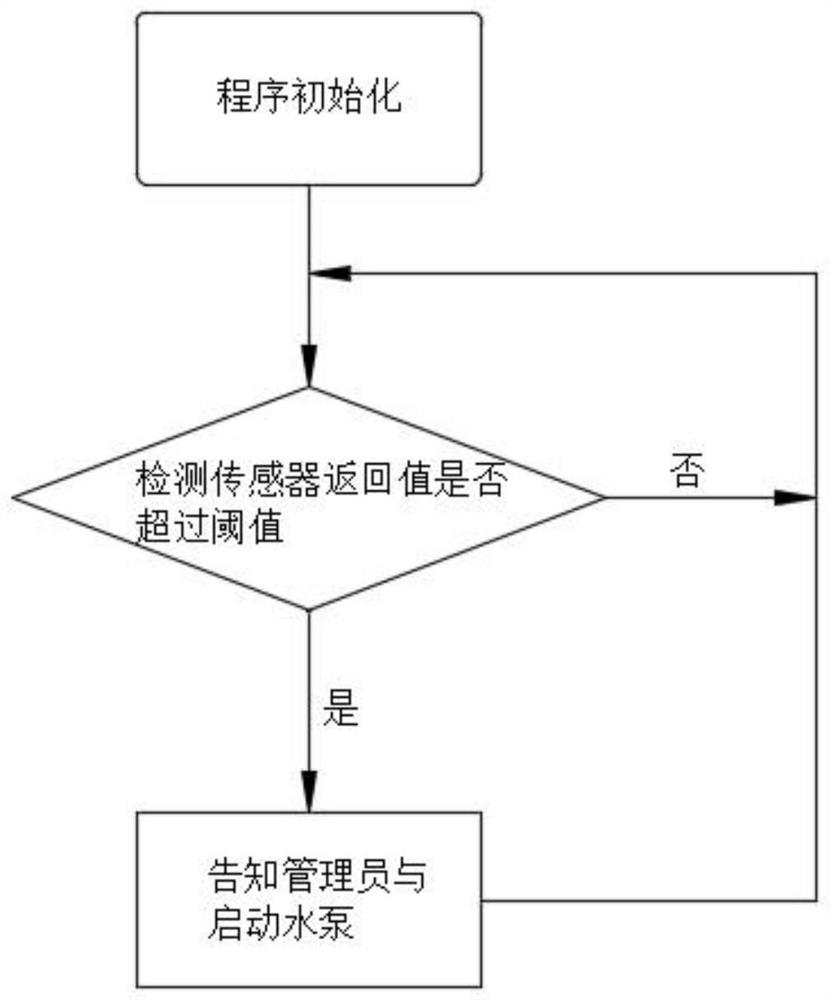

[0026] Specific embodiment 1, the fire detector monitors the occurrence of a fire. Flame combustion is an oxidation reaction process in which combustibles and oxygen or air undergo rapid exothermic and luminescent reactions. Desalination is performed in the form of flames. During the combustion process, fuel, oxygen, and combustion products are selected. Intermittent movement, heat energy and material transfer, combustion will produce a large amount of carbon dioxide at the same time, and carbon monoxide will be produced at the same time in a closed or semi-closed space, which is a gas that is extremely harmful to the human body. Carry out environmental detection, and the fire detector includes a flame sensor 3 that detects a special spectral range, a large-range high-temperature temperature sensor 4 and a carbon monoxide sensor 5;

[0027] Controller 2 has 14 digital pins and 1 analog pin, which can be used in multiple communication methods such as serial port, IIC, and SPI. C...

specific Embodiment 2

[0028] Specific embodiment 2, the selection of controller 2 requires low computing power, low delay and WiFi function during R&D and design. For this purpose, WiFiduino controller is selected. WiFiduino-8266 uses esp8266 as the core development board, compared with traditional Arduino controllers , WiFiduino-8266 provides WiFi support, and cooperates with the IoT software platform blinker to build IoT projects more easily;

specific Embodiment 3

[0029] Specific embodiment 3, in addition, the advantage of choosing the controller 2 is that there is a supporting mobile phone APP that can easily realize communication and operation monitoring between devices, and the development aspect is compatible with Arduino IDE, so there is almost no getting started cost for those who have used Arduino before;

[0030] The fire detector includes a flame sensor 3, a temperature sensor 4 and a carbon monoxide sensor 5. The flame sensor 3 is used to detect a fire source or a light source with a wavelength in the range of 760-1100nm. The flame sensor 3 has a detection angle of 60 degrees and two M3 installation holes Fixed installation, the working environment temperature range of flame sensor 3 is -25~85℃;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com