Cement and coral sand mixed type substratum and manufacturing and application method thereof

A technology of coral sand and attachment base, which is applied in the fields of application, climate change adaptation, fish farming, etc., can solve problems such as inability to spread in a large area, adverse effects on the growth of giant clam spat, damage to the coastal environment of coral reefs, etc., to achieve growth speed And survival rate, reliable technical support, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

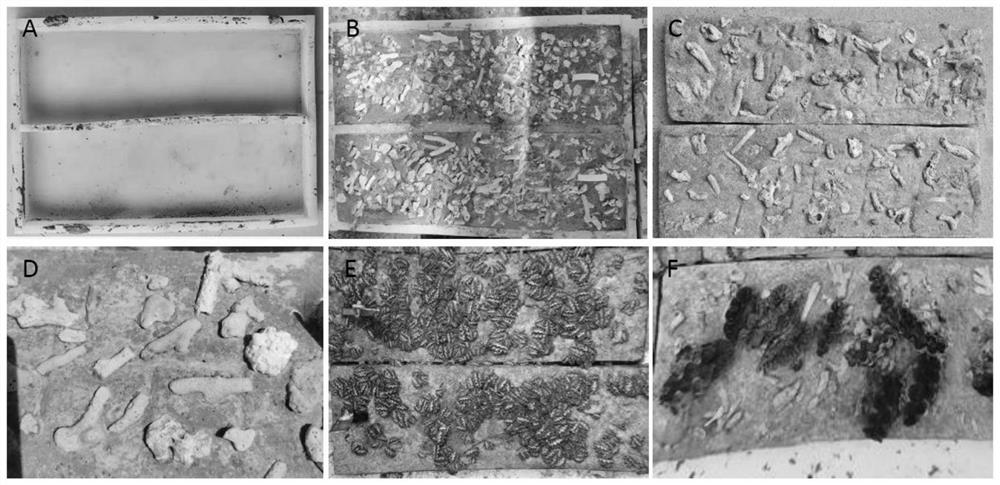

[0020] Such as figure 1 As shown, the preparation and application method of the cement coral sand mixed type attachment base of the present embodiment comprises the following steps:

[0021] a. Material preparation: On March 30, 2020, coral bones and coral sand were collected at the beach in front of the Hainan Tropical Marine Biology Experimental Station of the Chinese Academy of Sciences, and washed with clean water for later use. Use the sieve silk net to dry out the coral sand with a particle size of 0.5-0.8mm and the coral bone with a size of 2-4 cm.

[0022] b. Production of the attachment base mold: On April 1, 2020, a rectangular mold with an inner diameter of 40 x 60 cm and a side length of 40 cm x 60 cm is made of silica gel for use, and the middle is separated;

[0023] c. Preparation of attachment base: On April 2, 2020, mix Portland cement and coral sand with a particle size of 0.5-0.8mm in a mass ratio of 1:2, then add an appropriate amount of water and stir eve...

Embodiment 2

[0027] a. Material preparation: On March 20, 2021, coral bones and coral sand were collected from the beach in front of the Hainan Tropical Marine Biology Experimental Station of the Chinese Academy of Sciences, and washed with clean water for later use. Use the sieve silk net to dry out the coral sand with a particle size of 0.5-0.8mm and the coral bone with a size of 2-4 cm.

[0028] b. Production of the attachment base mold: On March 23, 2021, a rectangular mold with an inner diameter of 40 x 60 cm and a side length of 40 cm x 60 cm is made of silica gel for spare use, separated in the middle;

[0029] c. Preparation of attachment base: On March 25, 2021, mix Portland cement and coral sand with a particle size of 0.5-0.8mm in a mass ratio of 1:2, then add an appropriate amount of water and stir evenly, and inject into the silicone base in step b In the mould, 20 adhesive bases with a size of 20×30 cm and a thickness of 2 cm were made. After the cement mortar is poured into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com