High polymer material pre-filled syringe with needle and forming process of high polymer material pre-filled syringe

A polymer material and molding process technology, applied in the field of medical packaging, can solve the problems of heavy metal tungsten residue, unstable pH value, protein adsorption, etc., and achieve the effect of small specific gravity, no risk of explosion, and no protein adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

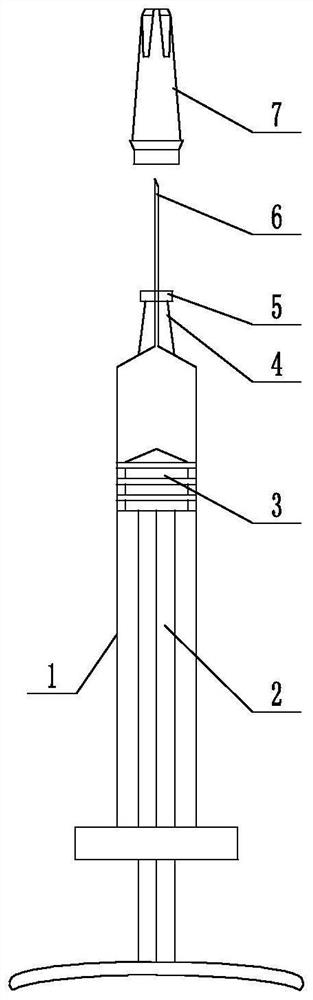

[0036] Such as figure 1 As shown, the described polymer material prefilled syringe with a needle includes a syringe 1, an injection needle 6 and an injection needle protective cap 7, the material of the syringe 1 is cycloolefin polymer, and the upper part of the syringe 1 is provided with a The fixing part 4 for fixing the injection needle 6 is provided with a plurality of reinforcing ribs on the fixing part 4, and the upper part of the fixing part 4 is provided with a protective cap protrusion 5, and the injection needle 6 is embedded in the upper part of the syringe 1, and is connected with the syringe 1 One piece. The injection needle protective cap 7 includes a polypropylene protective shell and a butyl rubber protective chamber arranged in the protective shell.

[0037] The polymer material prefilled syringe with a needle of the present invention is supplied to pharmaceutical companies in the form of an assembly. It is mainly used in the packaging of small-volume inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com