Microscope observation stage and use method thereof

A microscope and stage technology, which is applied in the direction of microscope, test sample preparation, discharge tube, etc., can solve the problems that affect the adsorption of sample particles, cannot ensure that the sample liquid is completely dried, and cross-contamination, so as to reduce the probability of cross-contamination , The effect of reducing the number of clamping substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Reference will now be made in detail to exemplary embodiments of the present invention, examples of exemplary embodiments are illustrated in the accompanying drawings. Whenever possible, the same component symbols are used in schemas and descriptions to represent the same or similar parts.

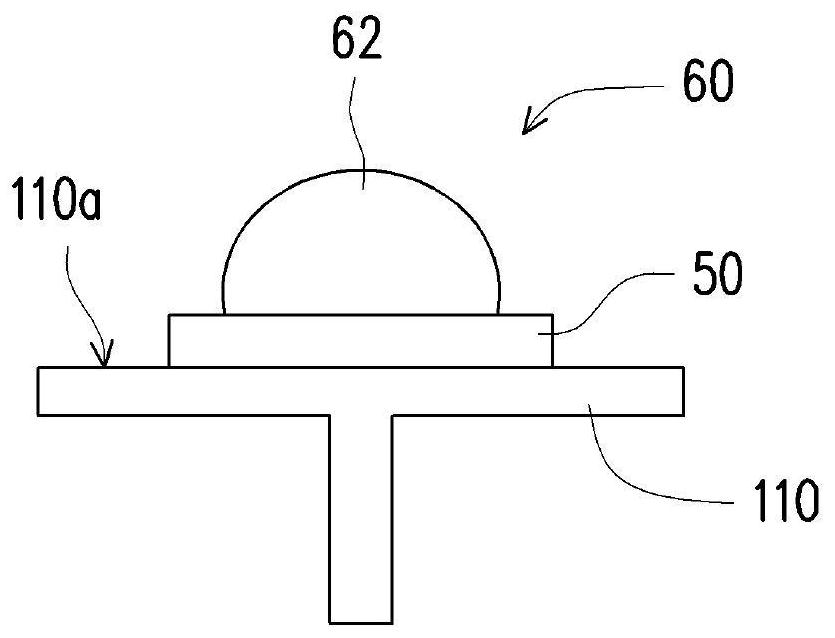

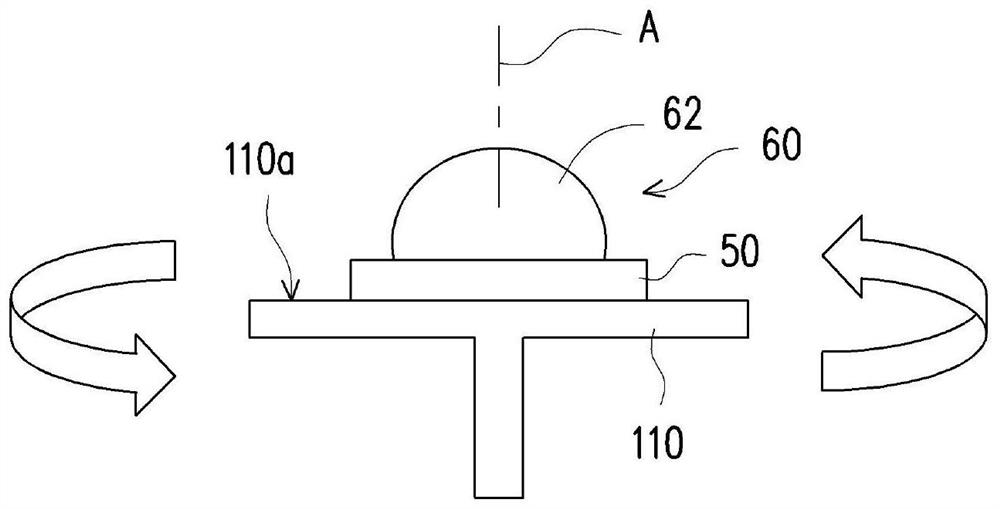

[0021] Figure 1 Is an embodiment of the present invention is a block diagram of a microscope observation stage. Figures 2A through 2F Illustrated Figure 1 The operation of the microscope observation stage. Figure 3 Illustrated Figure 2A The sample particles in the droplets are adsorbed by the substrate, which is schematically plotted Figure 2A A local enlargement of the substrate. Please refer to Figure 1 、 Figure 2A and Figure 3 , the microscope observation stage 100 of the present embodiment includes a rotating seat 110 and a drive unit 120. The rotating seat 110 is suitable for carrying the substrate 50 by its bearing surface 110a, the substrate 50 is suitable for bearing droplets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com