A waste gas treatment method for dynamic fluidized bed staged adsorption that realizes high efficiency and energy saving

A high-efficiency, energy-saving, waste gas treatment technology, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of lack of broad-spectrum adsorption, high operating costs, and fast desorption cycles, and reduce thermal desorption. Potential safety hazards, improving desorption efficiency, and reducing the effect of effective life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

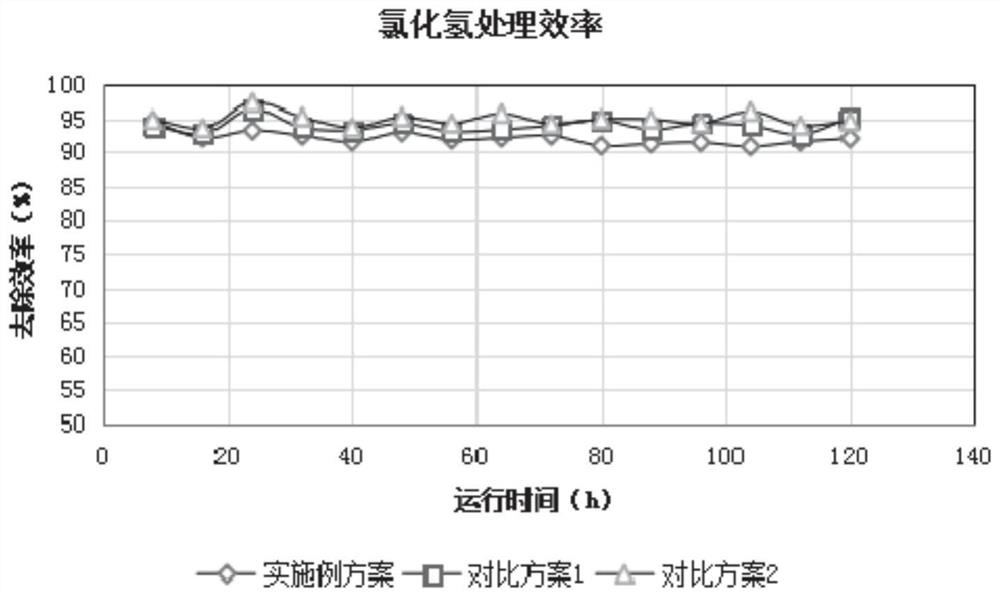

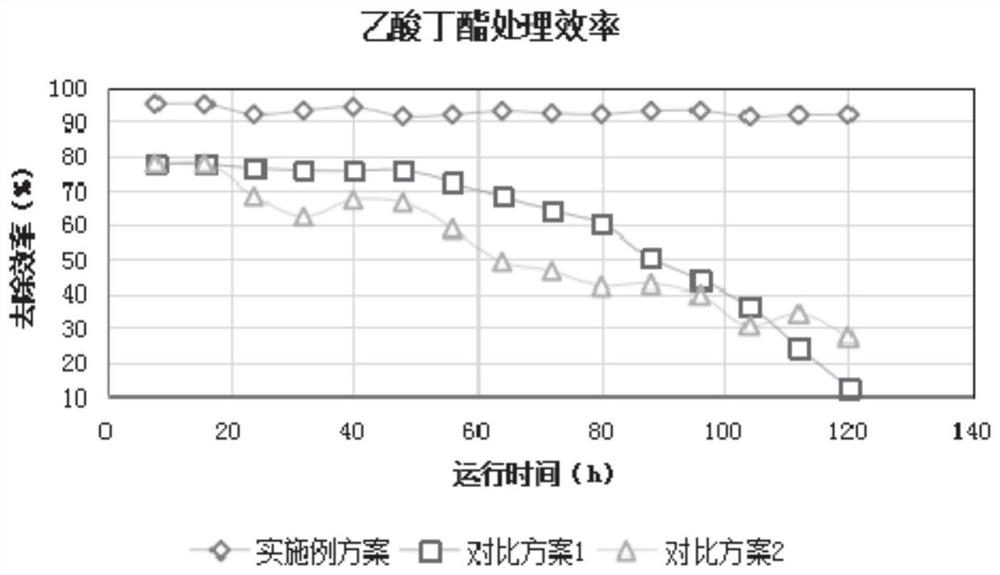

[0034] Exhaust gas working condition: exhaust air volume 100Nm 3 / h, the exhaust gas contains 30mg / m of hydrogen chloride 3 , butyl acetate 100mg / m 3 , toluene 50mg / m 3 , This project requires the exhaust gas treatment device to have a treatment efficiency of more than 90% for various pollutants.

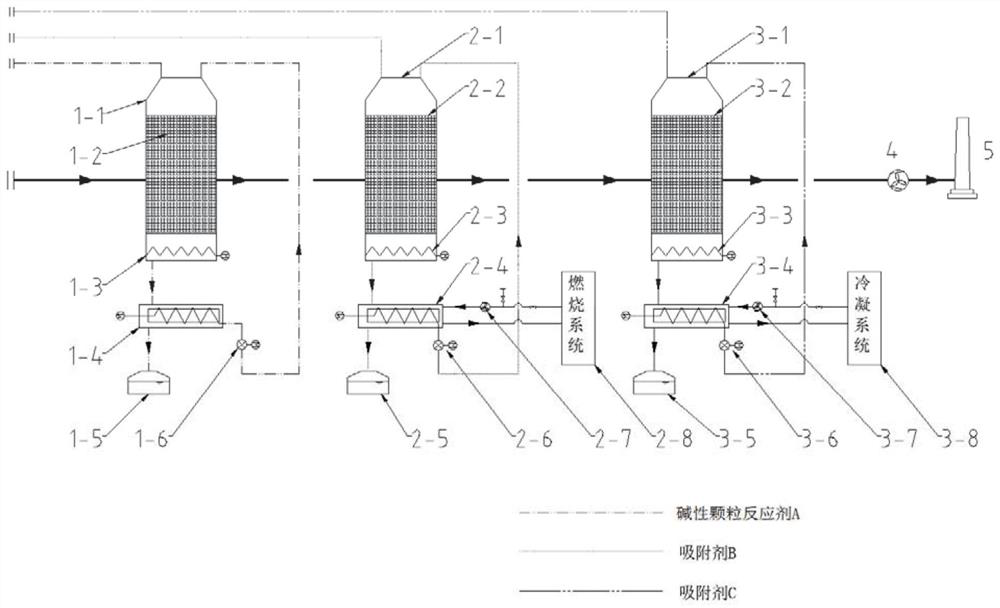

Embodiment approach

[0035] Implementation plan: use dry calcium carbonate adsorption method + molecular sieve system adsorption (thermal desorption combustion) + activated carbon system adsorption (steam desorption condensation) to treat waste gas. First, the exhaust gas enters the first-stage adsorption bed, and the adsorption bed is filled with granular calcium carbonate with a particle size of 8 mm. After the exhaust gas is reacted in the alkaline adsorption bed, hydrogen chloride is removed, and the surface of the granular calcium carbonate reacts with hydrogen chloride to form calcium chloride. The bottom surface reacts The calcium carbonate is transported to the surface grinder through the bottom conveyor, and the surface grinder strips the calcium chloride on the surface from the calcium carbonate particles, and after recovering the ability to absorb acid gas, it is transported to the primary adsorption bed through the screw feeder.

[0036] After the exhaust gas passes through the first-st...

comparative approach 1

[0039] Comparison scheme 1: Alkaline washing spray tower + replaceable activated carbon is used for treatment. The alkali washing spray tower absorbs hydrogen chloride through lye, and the organic matter is discharged after being adsorbed by activated carbon. The saturated activated carbon is treated as hazardous waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com