Device system and method based on iron and steel industry multi-energy storage

A technology for iron and steel industry and energy storage system, which is applied in the direction of electric energy storage system, circuit device, battery circuit device, etc. It can solve the problems of multi-photovoltaic power waste, large power generation, and intermittent photovoltaic power generation, so as to improve production efficiency and Production benefits, increasing energy storage capacity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

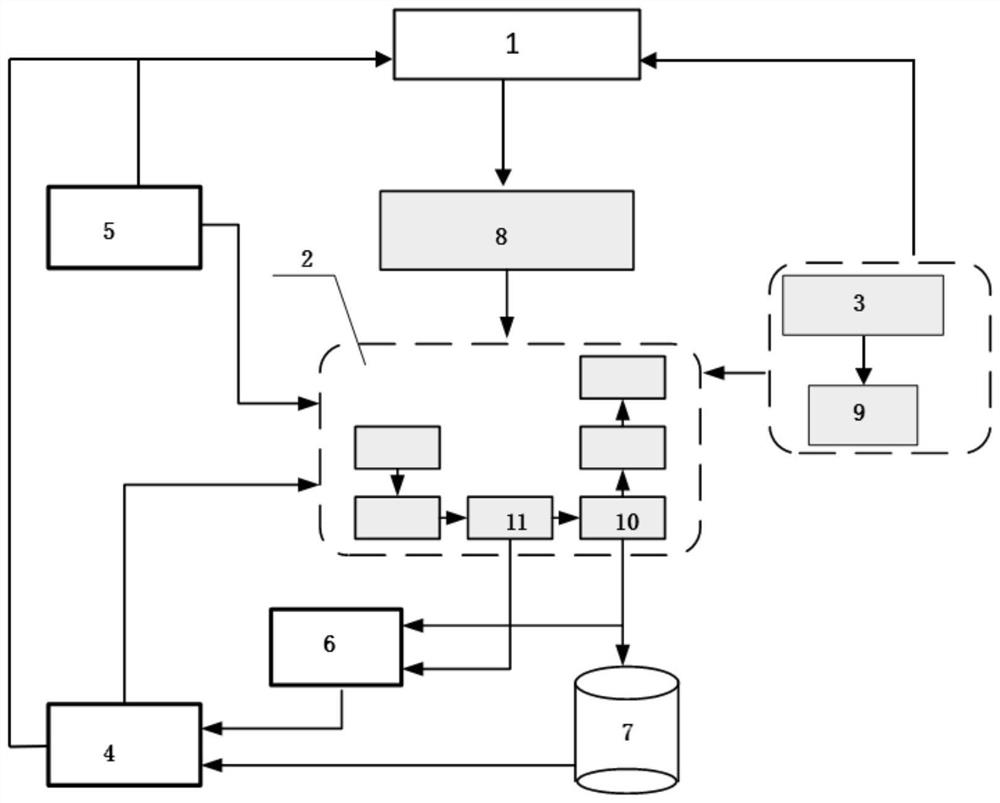

[0060] This embodiment provides a device system based on multi-energy storage in the iron and steel industry, such as figure 1 As shown, the device system includes a power supply system 1, an electric load system and an energy storage system; the power supply system 1 includes a new energy power generation system, a gas self-generation system 4 and a power grid 5; the electric load system includes a steel production system Process system 2; the energy storage system includes a heat storage energy storage system 6, a gas cabinet energy storage system 7, an air separation energy storage system 8 and a chemical energy storage system 9; the new energy power generation system includes a photovoltaic power generation system 3;

[0061] The outlet of the photovoltaic power generation system 3 is connected to the chemical energy storage system 9; the outlet of the photovoltaic power generation system 3 and the outlet of the chemical energy storage system 9 are connected to the iron and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com