Programmable building block motor module, building block assembly and design method

A motor module and combination technology, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of difficulty in switching between different working modes, restricting matching, and restricting building block products, etc., to achieve strong functional and structural matching, improve The effect of matching degree and combination forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

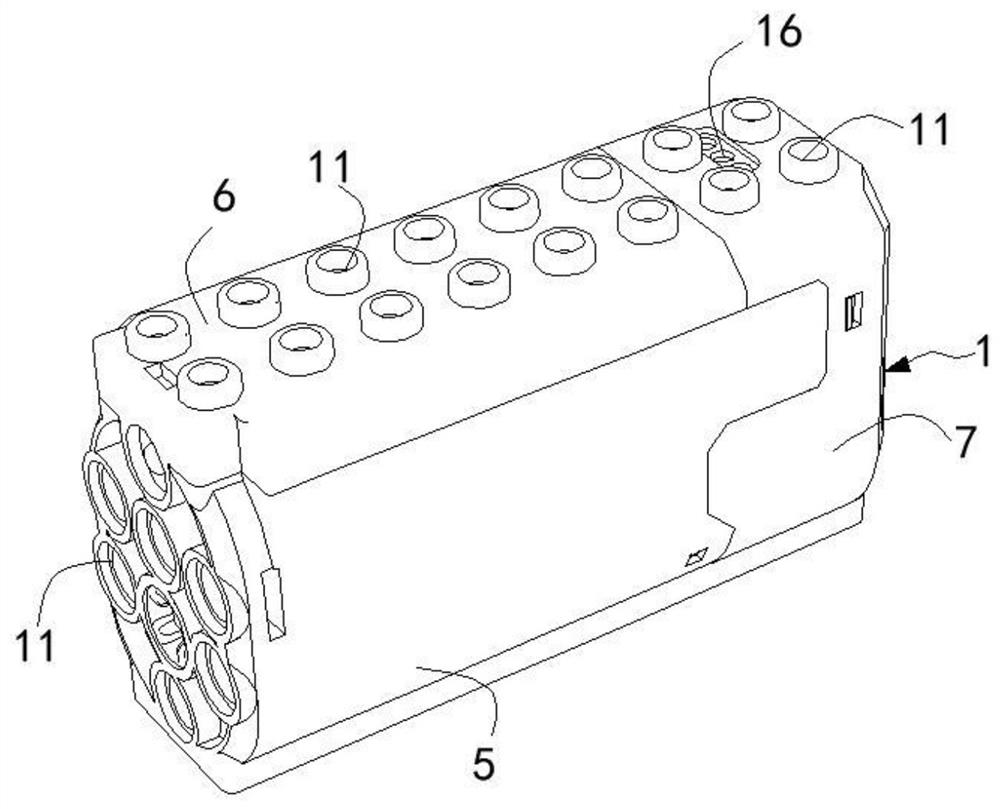

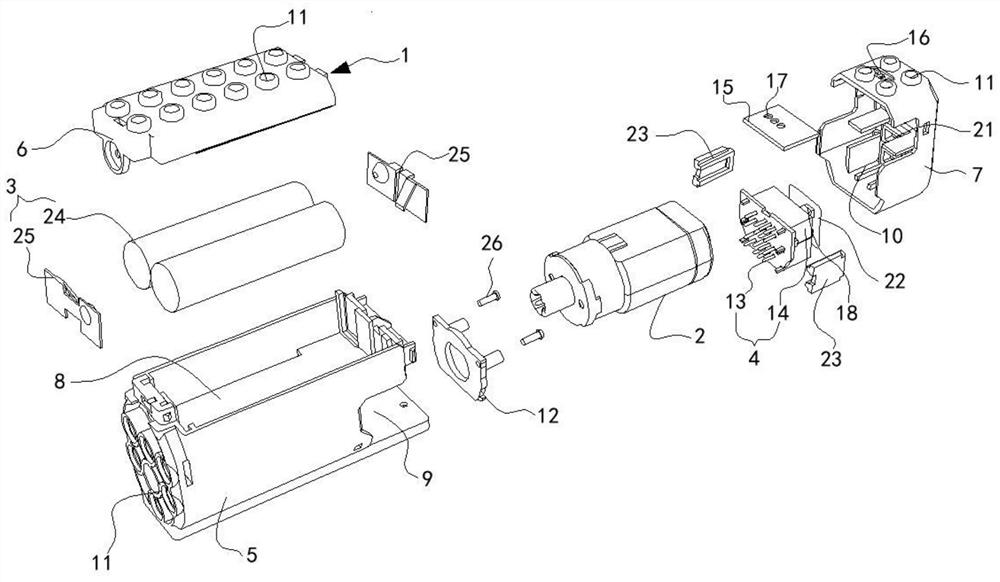

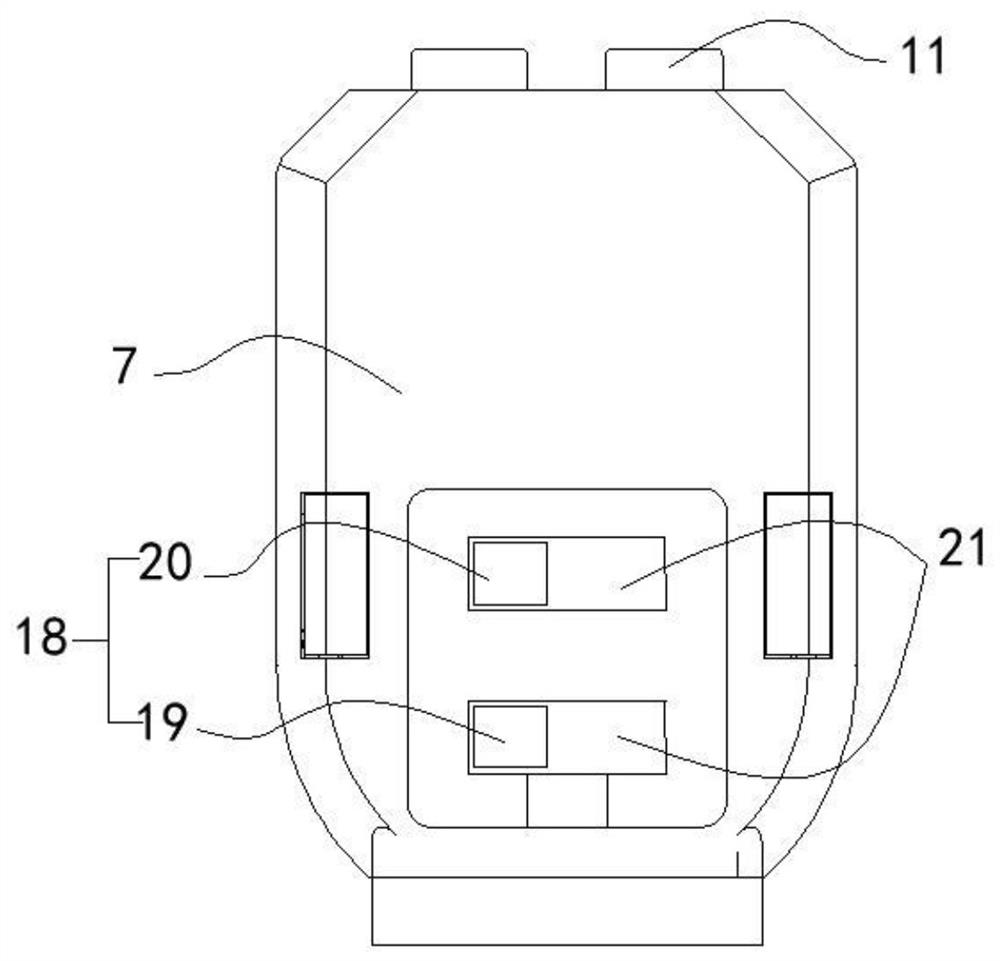

[0054] See attached Figure 1-9 , the programmable building block motor module structure provided by the embodiment of the present invention, which includes a detachable housing 1, a micro motor 2, a power supply device 3, a control circuit 4 and sensors (such as infrared sensors, voice control sensors, illuminance sensors, gyroscopes etc.); the micro motor 2, the power supply device 3, the control circuit 4 and the sensor are all arranged inside the housing 1.

[0055] After the various parts of the programmable building block motor module are combined with each other, its overall outline is an approximately rectangular square, and the ratio of the length, width and height of the square is: 8: (3-4): (4-5 ); and the length is based on 8mm as the standard base, which is an integer multiple of the standard base; in this embodiment, the actual dimensions of the cube length, width and height are: 64mm, 25mm, 37mm, in other embodiments, you can According to actual needs, select w...

Embodiment 2

[0090] see Figure 12-13 , the programmable building block motor module structure, building block assembly and design method thereof provided by the embodiment of the present invention are basically the same as Embodiment 1, the difference is that the programmable building block motor module quantity, position, the splicing of the building block assembly and Its working mode is different.

[0091] The building block assembly provided by the embodiment of the present invention is a dual-drive electric trolley spliced by a plurality of electric building block modules, with rear drive, and can automatically track or drive automatically (obstacle avoidance) according to pre-programmed. The building block combination includes two programmable building block motor modules, which are the first programmable building block motor module A, the second programmable building block motor module B, and the two programmable building block motor modules A and B. In the building block combina...

Embodiment 3

[0094] see Figure 14 , the programmable building block motor module structure, building block assembly and design method thereof provided by the embodiment of the present invention are basically the same as Embodiment 2, the difference is that the programmable building block motor module quantity, position, splicing and Its working mode is different.

[0095] The building block combination provided by the embodiment of the present invention is a dual-drive / single-drive electric sports car, which includes two programmable building block motor modules A and B, and the two programmable building block motor modules A and B are within the width of the building block combination. Arranged in parallel (front and back) in the direction, the overall outline is flush with each other in all directions, and they are all set at the back section of the building block combination, A is behind and B is in front, and the overall center of gravity of the building block combination is set on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com