Bullet cabinet made of high-density and high-hardness material

A high-hardness, high-density technology, applied in the field of bullet cabinets, can solve problems such as inconvenient movement, achieve the effect of easy operation and avoid collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

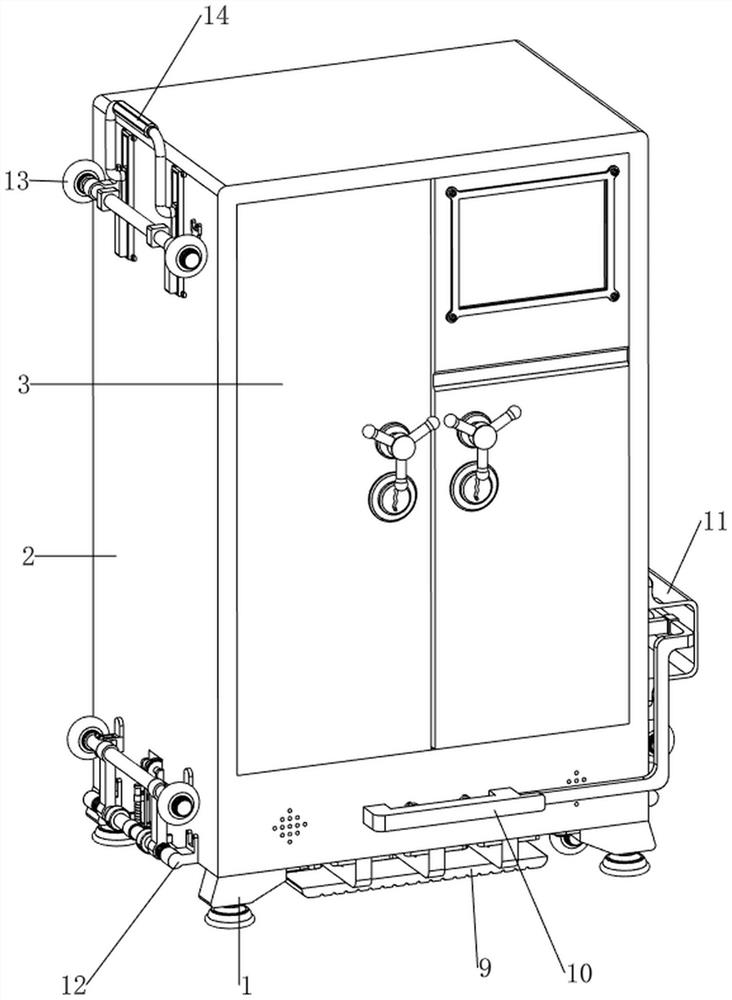

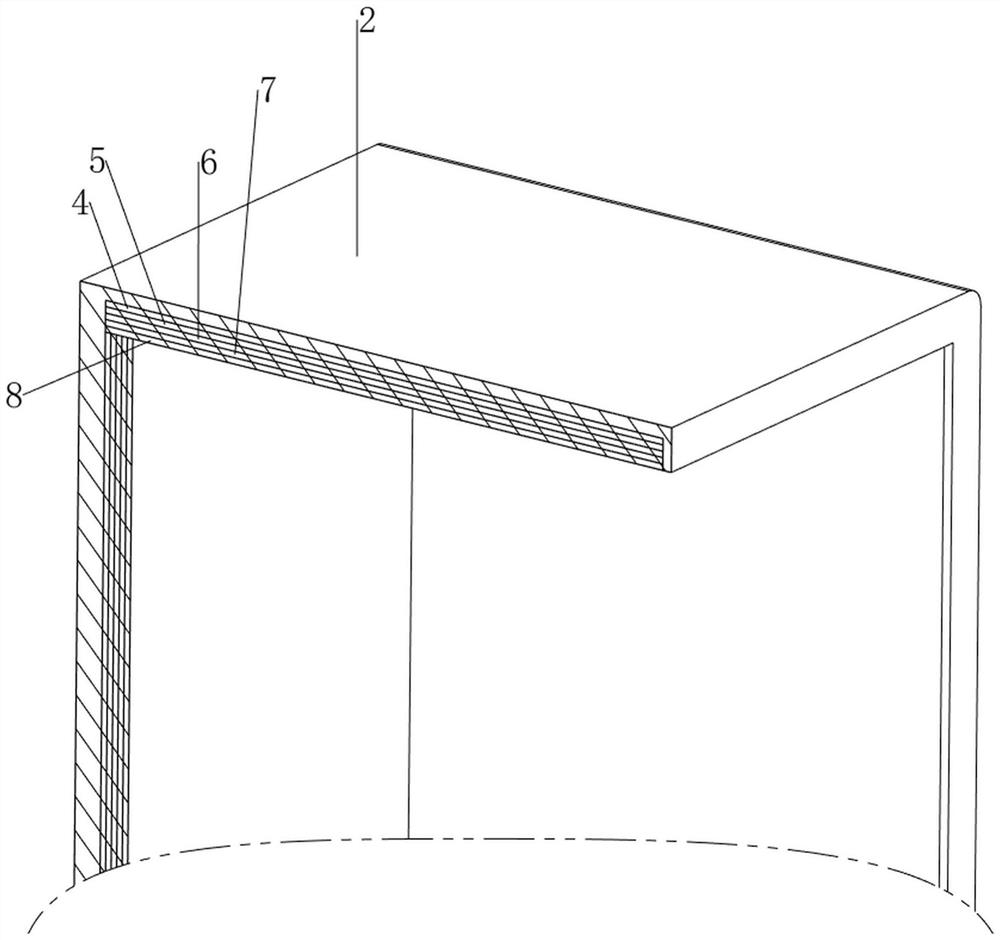

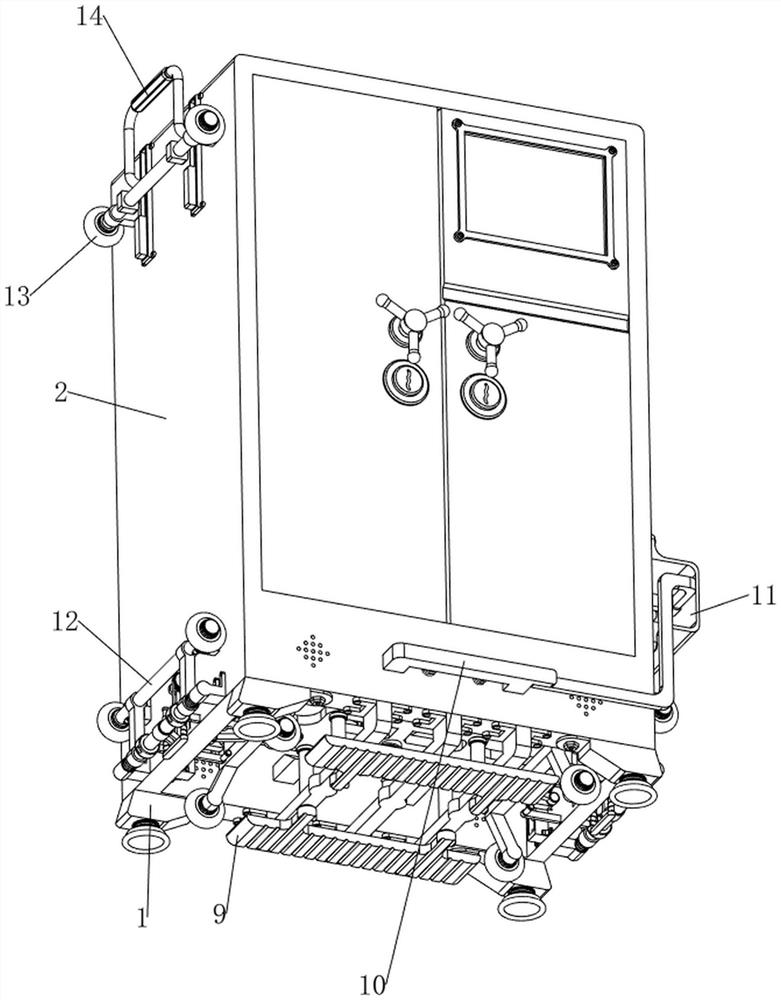

[0039] A bullet cabinet made of high-density and high-hardness materials, such as figure 1 , figure 2 and image 3 As shown, it includes a foot 1, an outer frame 2, a baffle 3, an anti-drilling steel plate 4, an anti-rust zinc layer 5, an anti-oxidation coating 6, a micro-carbon alloy steel plate 7, an encrypted steel plate 8, a support mechanism 9 and a displacement Mechanism 10, the number of legs 1 is four, and the top of the four legs 1 is fixed with an outer frame 2 through bolts, and the front side of the outer frame 2 is symmetrically arranged with a baffle 3 in a hinged manner, and the baffle 3 is used to open With the outer frame 2 closed, a password lock for anti-theft is provided in the middle of the front side of the two baffles 3, and an anti-drilling steel plate 4, an anti-rust zinc layer 5, an anti-oxidation coating 6, a micro Carbon alloy steel plate 7 and encrypted steel plate 8, anti-drilling steel plate 4, anti-rust zinc layer 5, anti-oxidation coating 6,...

Embodiment 2

[0044] On the basis of Example 1, such as figure 1 , Figure 9 and Figure 10 As shown, a push mechanism 11 is also included, which is convenient for people to push the first wedge block 101. The push mechanism 11 includes a frame body 111, a second sliding sleeve 112, a push block 113, a first handle bar 114, and a third support 115 and two-way threaded rod 116, the lower part of the outer frame 2 is symmetrically connected with the frame body 111 by bolts, the lower part of the outer frame 2 is symmetrically provided with the second sliding sleeve 112, and the second sliding sleeve 112 is positioned at the frame on the same side. Inside the body 111, the right side of the second sliding sleeve 112 is slidingly provided with a push block 113, and the push block 113 is in contact with the adjacent first wedge block 101. The bracket 115 is rotatably connected with a bidirectional threaded rod 116 between the two third brackets 115 , the middle part of the bidirectional thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com