Hydrogen-heat-electricity combined supply integrated system based on reactive metal hydrolysis hydrogen production

An active metal, hydrolysis hydrogen production technology, applied in non-metallic elements, hydrogen, circuits, etc., can solve the problems of low kinetics and reaction efficiency, and achieve the effect of improving the utilization rate of resources, efficient chemical reaction, and ensuring continuous power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

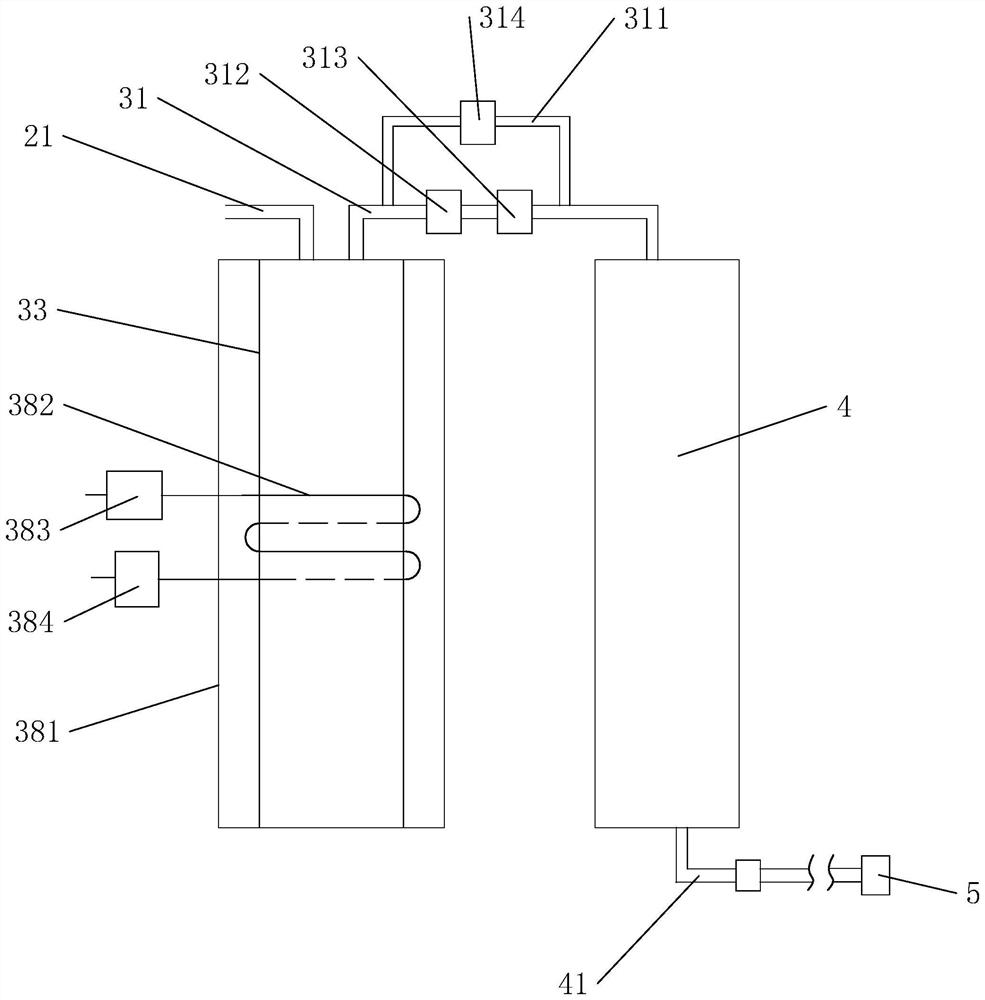

[0056] The application will be described in further detail below in conjunction with the accompanying drawings.

[0057] The embodiment of the present application discloses a hydrogen-heat-electricity cogeneration integrated system based on active metal hydrolysis to produce hydrogen.

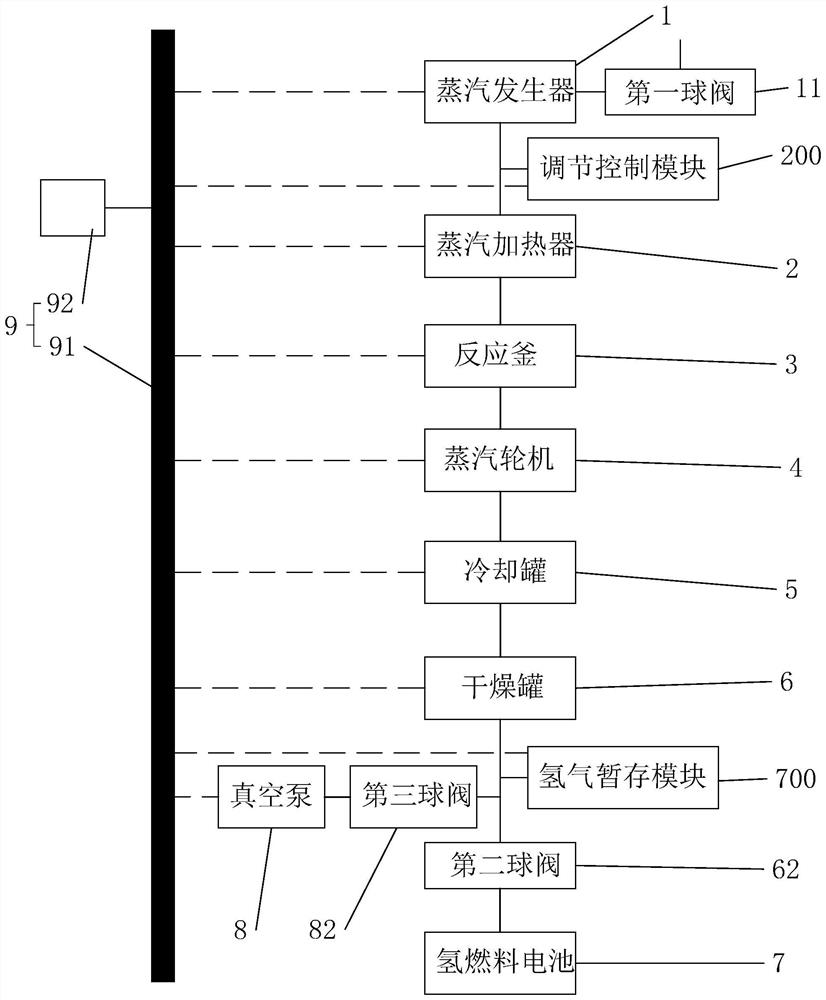

[0058] refer to figure 1 , the hydrogen-heat-electricity cogeneration integrated system based on the hydrolysis of active metals includes a steam generator 1, a steam heater 2, a regulation control module 200, a reactor 3, a steam turbine 4, a condensation tank 5, a drying tank 6, a hydrogen A fuel cell 7 , a hydrogen temporary storage module 700 , a vacuum pump 8 and a control station 9 .

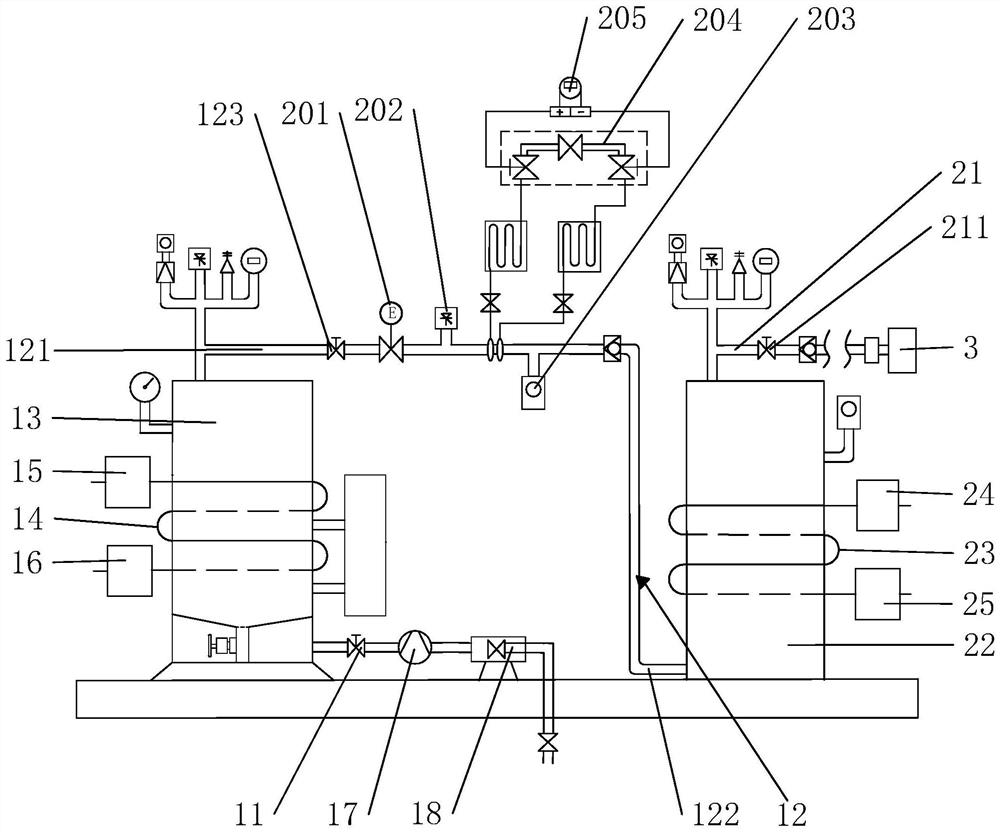

[0059] refer to figure 1 and figure 2 , the bottom of the steam generator 1 is provided with a water inlet pipeline, and a first ball valve 11 is arranged on the water inlet pipeline, the first ball valve 11 is opened, water enters the steam generator 1 through the water inlet pipeline, and tap water ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com