Nano blue diamond catalyst for fuel cell, preparation method and fuel cell

A fuel cell and catalyst technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of inability to apply alcohol fuel cells, limited commercial application, high price, etc., and achieve excellent Mechanical strength, low price, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

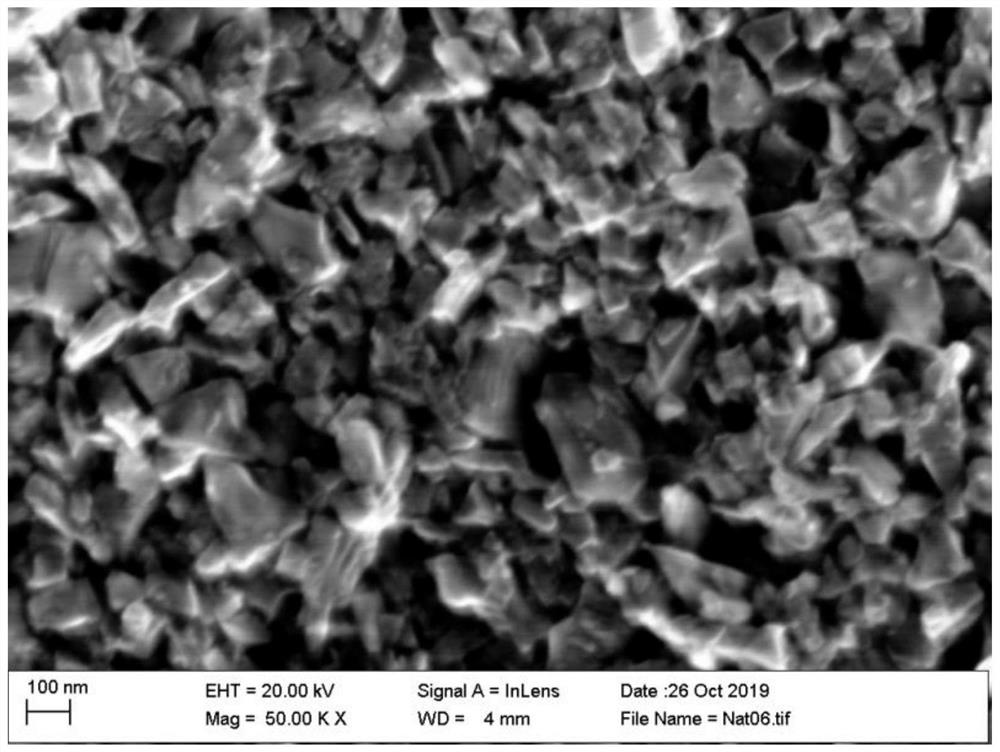

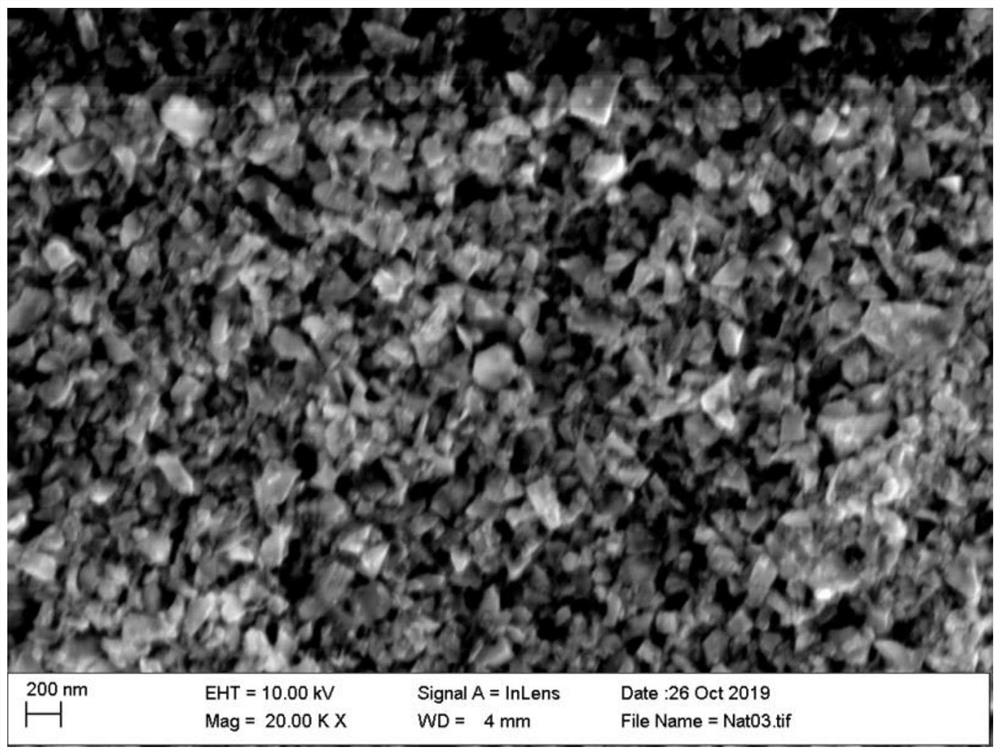

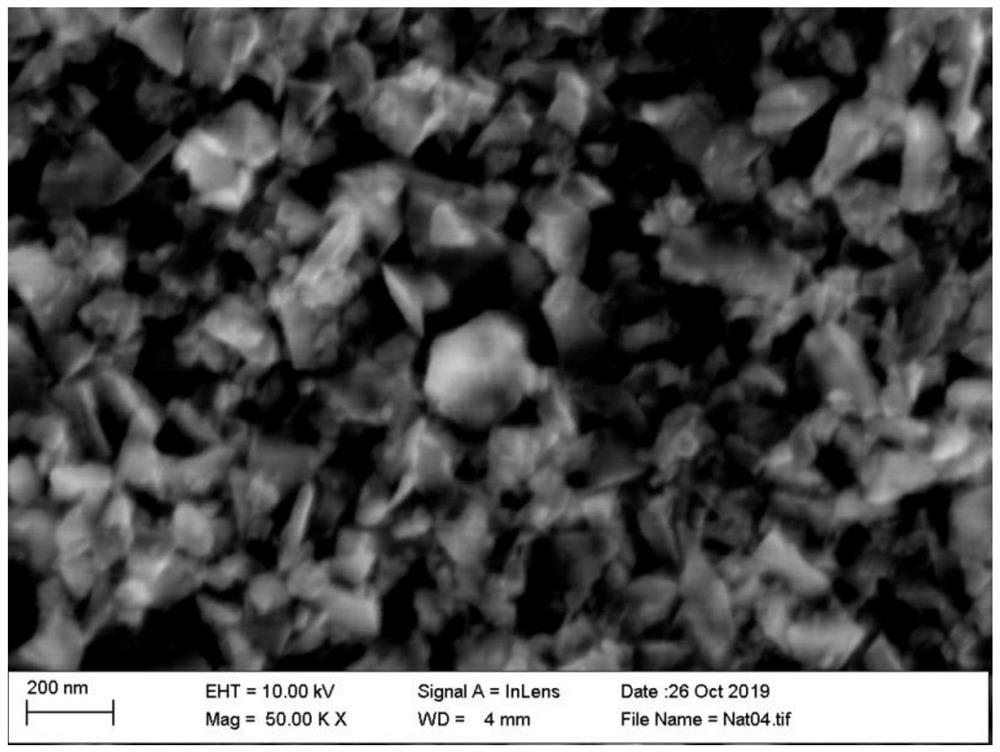

[0041] The invention provides a nano-blue diamond catalyst for a fuel cell and a preparation method thereof. The nano-blue diamond catalyst is a structure in which the outer conductive diamond wrapping layer wraps the inner core and is non-conductive diamond. The nano-blue diamond catalyst for the fuel cell provided by the invention The preparation method makes, comprises the steps:

[0042] Step S1:

Embodiment 01

[0044] The carbon-containing explosive is converted into diamond by an explosion method to obtain an intermediate product, and the intermediate product is screened to separate and obtain nano-diamond particles.

[0045] Among them, the principle of transforming the explosive method into diamond is: the carbon-containing explosive with negative oxygen balance is used as the raw material, and the oxygen in the explosive molecule is not enough to oxidize all the carbon into CO or CO during detonation. 2 , so there is free carbon in the detonation zone, and under the action of high pressure and high temperature in the detonation zone, the free carbon is partially transformed into diamond. The resulting product includes not only diamond, but also impurities such as graphite and amorphous carbon. In order to obtain the desired diamond powder, it needs to be screened and separated. The diameter of the isolated diamond nanoparticle is less than 20 nm. In a preferred embodiment of the ...

Embodiment 02

[0048] The diamond crystal is grown by a high temperature and high pressure method or a chemical vapor deposition method, and the diamond crystal is pulverized into micro-nano-level particles by physical means to obtain nano-diamond particles.

[0049] The high temperature and high pressure method uses a catalyst to convert carbon sources such as graphite into diamond under high temperature and high pressure conditions, while the chemical vapor deposition method includes hot wire method and microwave method. Under the condition of pressure lower than standard atmospheric pressure, carbon-containing gas and hydrogen gas are excited and dissociated, thus forming diamond.

[0050] Large sheets of diamond crystals are grown by high temperature and high pressure method or chemical vapor deposition method, and the grown large sheets of diamond crystals are crushed into micro-nano particles by physical means such as crushing and grinding.

[0051] For example, using the high temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com