Totally-synthesized flame-resistant rolling lubrication internal combustion engine oil special for warship and preparation method of fully-synthesized flame-resistant rolling lubrication internal combustion engine oil

An internal combustion engine oil, fully synthetic technology, applied in the field of lubricating oil, can solve the problems affecting engine power improvement, reduced lubricating effect, insufficient anti-oil film and sludge, etc., and achieve high thermal oxidation stability and thermal stability, high anti-wear performance and Oxidation resistance, the effect of reducing carbon deposits and varnish formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

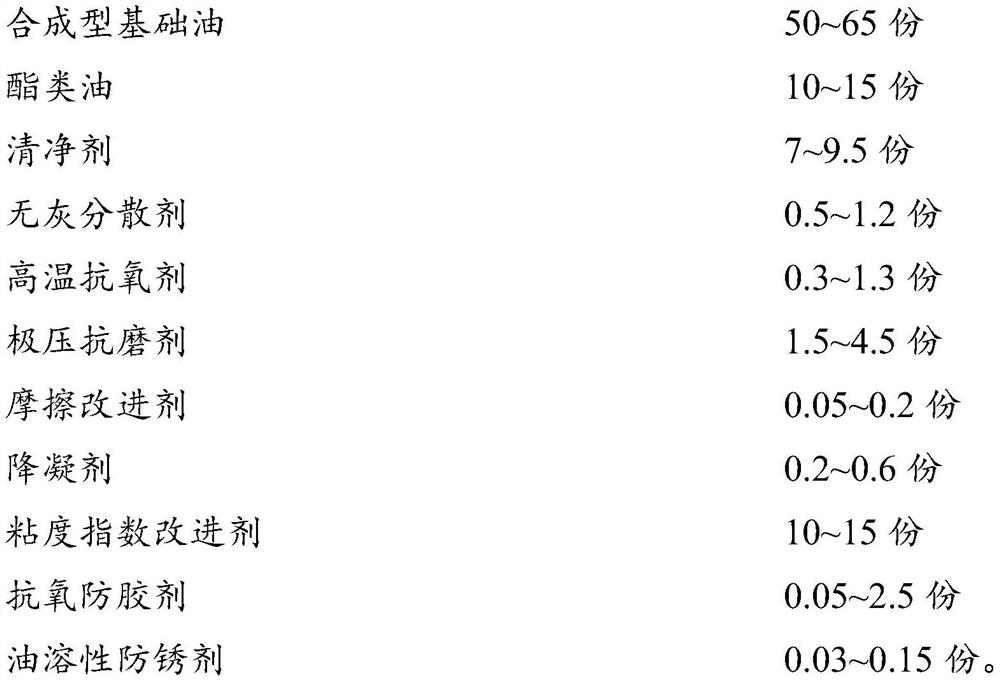

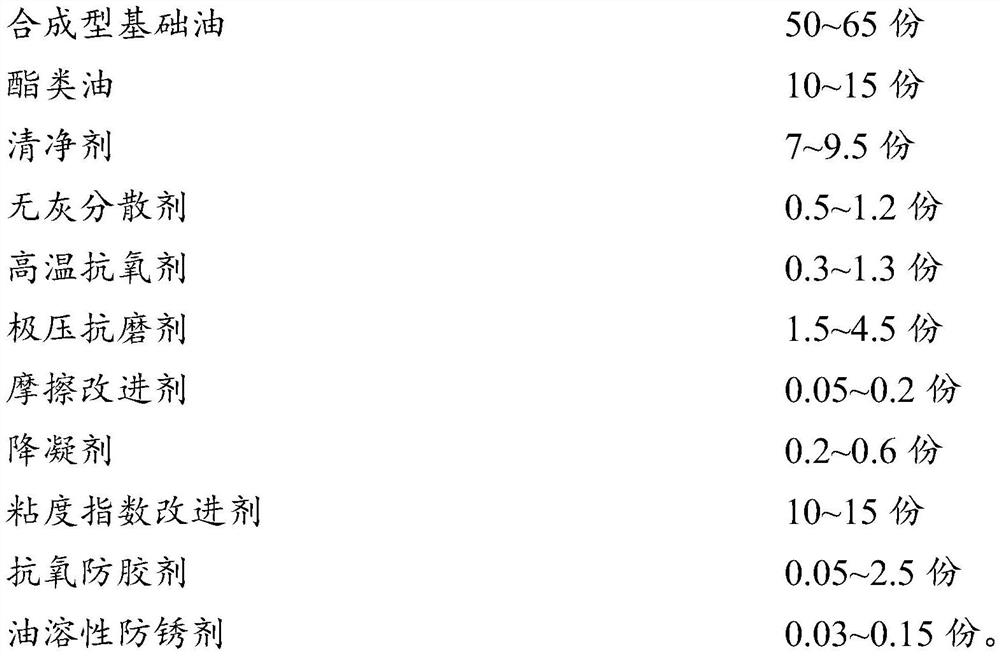

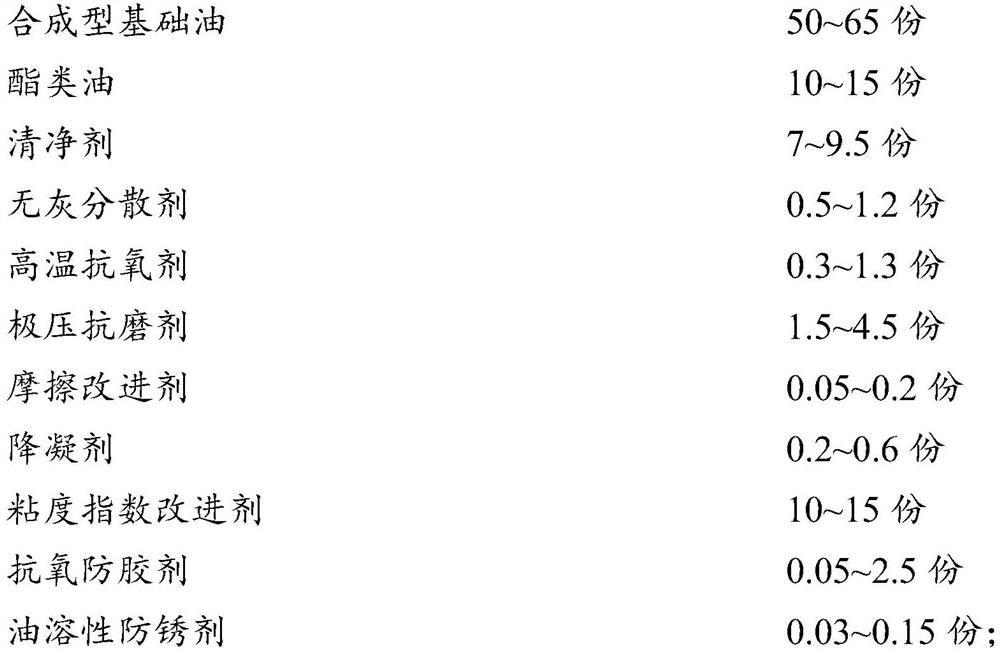

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a kind of preparation method of the internal-combustion engine oil special for warship of fully synthetic anti-combustion rolling lubrication, comprising the following steps:

[0049] (1) Heat the synthetic base oil and ester oil after mixing;

[0050] (2) After heating, add pour point depressant, viscosity index improver and mix, then add detergent, ashless dispersant, high temperature antioxidant, friction modifier and extreme pressure antiwear agent and mix;

[0051] (3) Add an anti-oxidation anti-adhesive agent and an oil-soluble anti-rust agent, and mix to obtain a fully-synthesized anti-flammability rolling lubrication special internal combustion engine oil for warships.

[0052] In the present invention, the step (1) is preferably heated to 60-65°C at a rotational speed of 50-80r / min after mixing, more preferably heated to 62-64°C at a rotational speed of 60-70r / min.

[0053] In the present invention, after adding the pour poi...

Embodiment 1

[0082] According to the ratio by weight, put 52 parts of synthetic base oil PAO10, 11 parts of 180I and 12 parts of diester oil into the reaction kettle in turn, start stirring, and heat to 60°C; first add 0.4 parts of pour point depressant, 12 parts of viscosity After the index improver, stir rapidly at 200r / min for 30 minutes, then add 7.5 parts of detergent, 1.0 part of ashless dispersant, 0.5 parts of high-temperature antioxidant, 0.1 part of friction modifier and 3 parts of Extreme pressure and anti-wear agent, continue to stir for 60-90 minutes, finally add 0.45 parts of anti-oxidation and anti-adhesive agent, 0.05 part of anti-rust agent, and stir at a speed of 160r / min for 80 minutes to mix well, then pump it to a storage tank and let it stand for 1 hour , that is, LGT 100 anti-combustion rolling lubrication performance of warship heavy-duty power transmission internal combustion engine oil.

Embodiment 2

[0084] According to the proportion by weight, put 51 parts of synthetic base oil PAO10, 10 parts of 180I and 12 parts of polyol ester oil into the reaction kettle in turn, start stirring, and heat to 63°C; first add 0.4 parts of pour point depressant, 13 parts of After the viscosity index improver, stir rapidly at 200r / min for 30 minutes, then add 9 parts of detergent, 1.0 part of ashless dispersant, 1.0 part of high temperature antioxidant, 0.1 part of friction modifier and 2.5 parts at 250 r / min 1 part of extreme pressure antiwear agent, continue to stir for 70 minutes, finally add 0.4 part of anti-oxidation and anti-adhesive agent, 0.05 part of anti-rust agent, and stir at a speed of 150r / min for 85 minutes to mix well, then pump it to a storage tank and let it stand for 1 hour , That is, LGT 300 anti-combustion rolling lubrication performance of warship heavy-duty power transmission internal combustion engine oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com