Adhesive and electrochemical device

A technology of adhesives and accelerators, applied in the field of energy storage, can solve problems such as poor moisture and heat aging resistance, meet performance requirements, meet bond strength, increase toughness and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

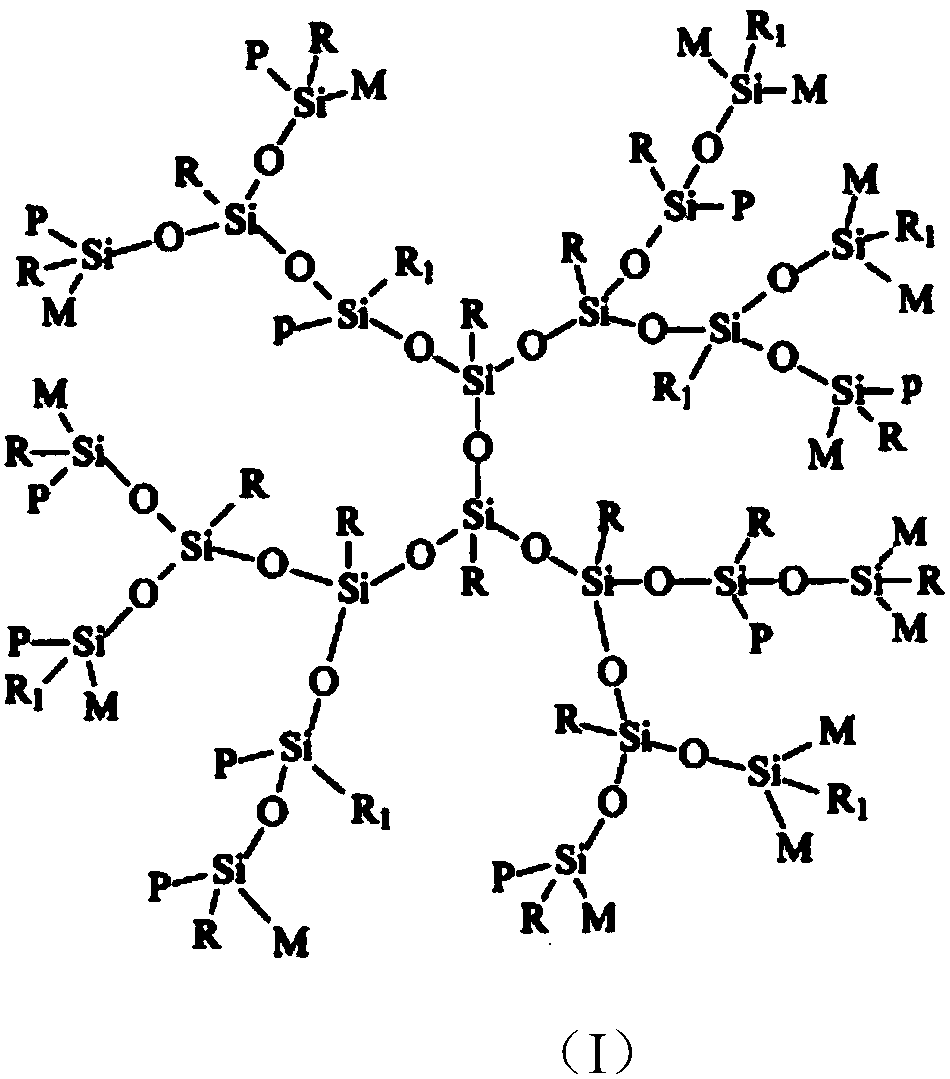

[0067] 1) Under stirring conditions, after adding 45.00g γ-methacryloxypropyltrimethoxysilane, 5.15g deionized water and 0.09g tetramethylammonium hydroxide (20% aqueous solution) into the three-necked flask, at 40 Reflux at constant temperature for 2 hours at °C to obtain solution A;

[0068] 2) Under stirring conditions, dissolve 30.89g of trimethylchlorosilane in 54.00mL of methanol to obtain solution B;

[0069] 3) Under the conditions of stirring and nitrogen protection, pour solution B into solution A at 60°C, and reflux at constant temperature at 60°C for 6 hours, and obtain the crude product after vacuum distillation;

[0070] 4) After the crude product is dissolved in dichloromethane, the insoluble matter is filtered off, and after vacuum distillation and vacuum drying, a hyperbranched silicone resin containing an active functional group of methacryloxypropyl is obtained.

Embodiment 1

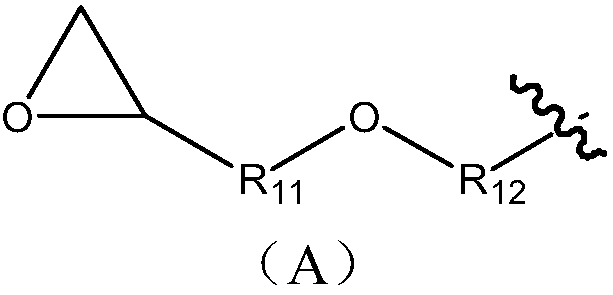

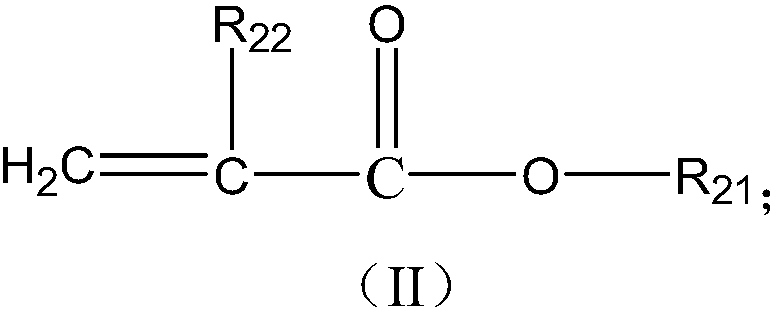

[0072] Component A: Take 40 parts by weight of methyl methacrylate, 5 parts by weight of styrene-butadiene-styrene block copolymer, and 30 parts by weight of methacryloyl methacrylate containing active functional groups obtained in the preparation examples. Hyperbranched silicone resin of oxypropyl, 0.05 parts by weight of N, N-dimethylaniline, 0.01 parts by weight of hydroquinone and 0.05 parts by weight of methyl silicone oil; B component: take 50 parts by weight of over Oxidized phthaloyl, 30 parts by weight of dimethyl phthalate, 2 parts by weight of styrene-butadiene-styrene block copolymer, mix components A and B evenly to obtain Adhesive1.

Embodiment 2

[0074] Component A: get 60 parts by weight of ethyl methacrylate, 20 parts by weight of nitrile rubber, 10 parts by weight of the hyperbranched silicone resin containing active functional groups obtained by the preparation example as methacryloxypropyl group, 0.05 parts by weight of n-butyraldehyde-aniline condensate, 0.01 parts by weight of benzoquinone and 0.05 parts by weight of methyl silicone oil; component B: get 70 parts by weight of lauroyl peroxide, 40 parts by weight of diphthalic acid di Ethyl ester and 4 parts by weight of diethyl phthalate, and components A and B were mixed uniformly to obtain adhesive 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com