A high-efficiency solar cell double-glass component processing equipment

A technology for solar cells and double-glass modules, applied in the field of solar cells, can solve the problems of EVA film folds and bubbles, unable to synchronize battery packs, low work efficiency, etc., so as to prevent wrinkles, reduce the number of glass turnovers, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

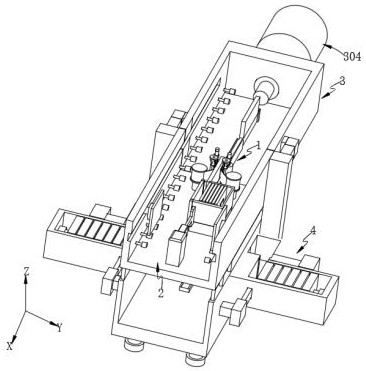

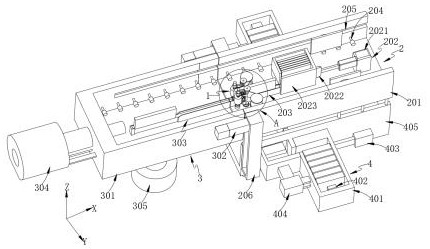

[0082] like Figure 1-2 As shown, a high-efficiency solar cell double-glass component processing equipment, including:

[0083] gluing unit 1;

[0084] Feeding unit 2, the feeding unit 2 is arranged at the lower part of the gluing unit 1;

[0085] a glass adding unit 3, the glass adding unit 3 is arranged at the discharge end of the feeding unit 2;

[0086] The enclosure panel installation unit 4, the enclosure panel installation unit 4 is arranged below the feed unit 2;

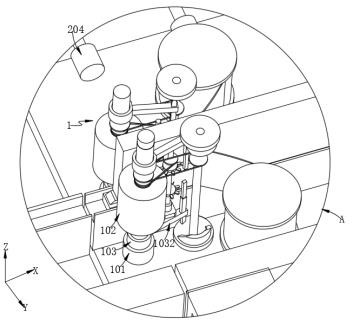

[0087] The gluing unit 1 includes a glue-melting pressure roller 102 , a positioning mechanism 105 and a smoothing mechanism 1037 sequentially arranged on the side of the glue-melting pressure roller 102 ;

[0088] When the battery assembly enters the glass adding unit 3 along the feeding unit 2 through the gluing unit 1, the glue pressing rollers 102 on both sides of the gluing unit 1 simultaneously press the glue film to the surface of the battery assembly, and the glue film is melted toward the surface...

Embodiment 2

[0140] like Figure 9 , Figure 11 , Figure 13 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0141] The enclosure panel installation unit 4 includes:

[0142] the third isolation plate 405;

[0143] a frame storage box 401, the frame storage box 401 penetrates through the side wall of the third isolation plate 405;

[0144] A second clamping transfer plate 4051 is connected to the bottom of the third isolation plate 405;

[0145] The frame storage box 401 is internally connected with a third cylinder 402;

[0146] A fourth cylinder 403 is provided on the side of the frame storage box 401 located in the +X direction;

[0147] A fifth cylinder 404 is provided on the side of the frame stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com