Intelligent kitchen waste comprehensive treatment device

A comprehensive treatment and kitchen technology, applied in filtration treatment, grease/oily substance/float removal device, multi-stage water treatment, etc. or blockage of the drainage system, etc., to achieve the effect of simple and intelligent operation, compact overall structure and reduced power consumption of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

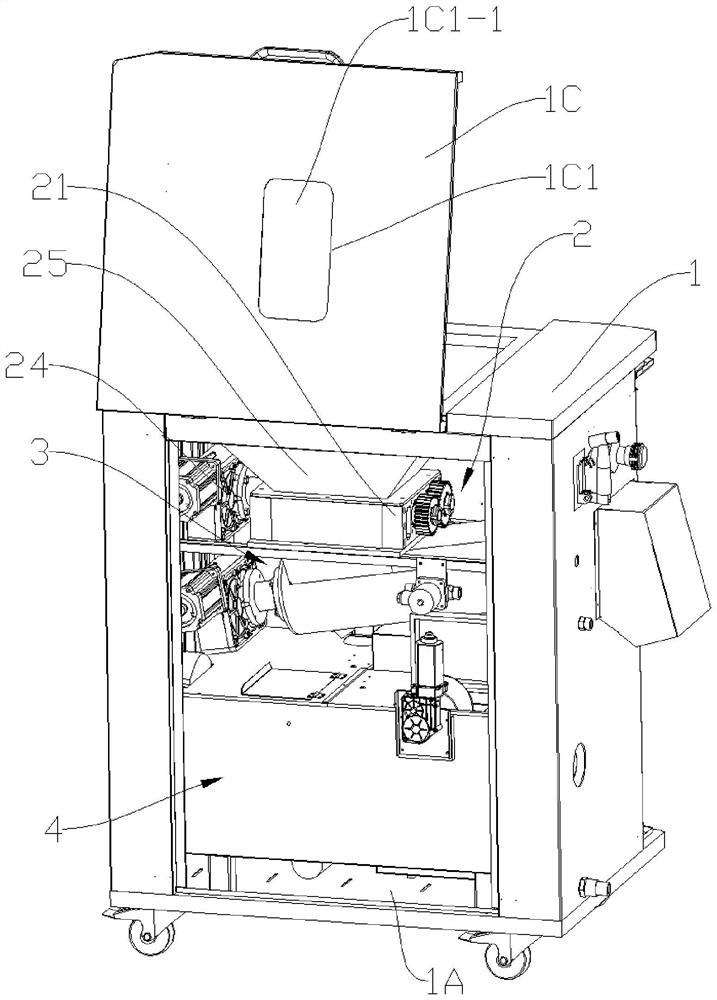

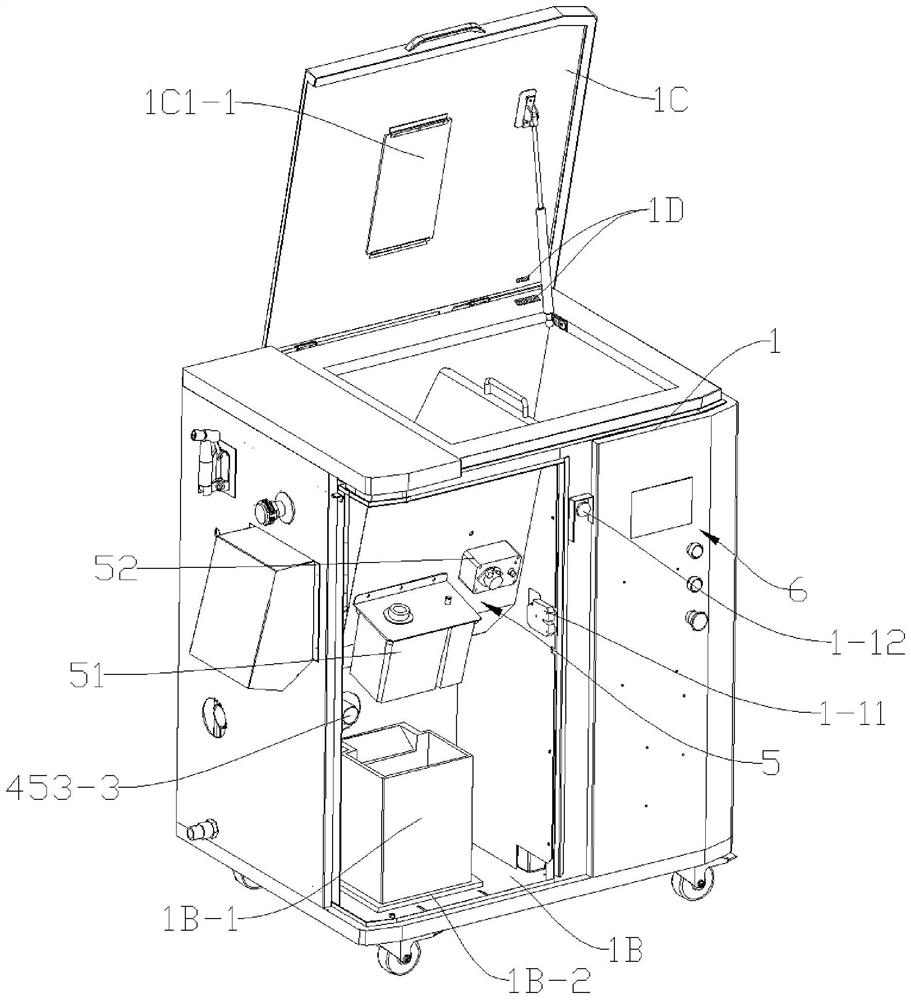

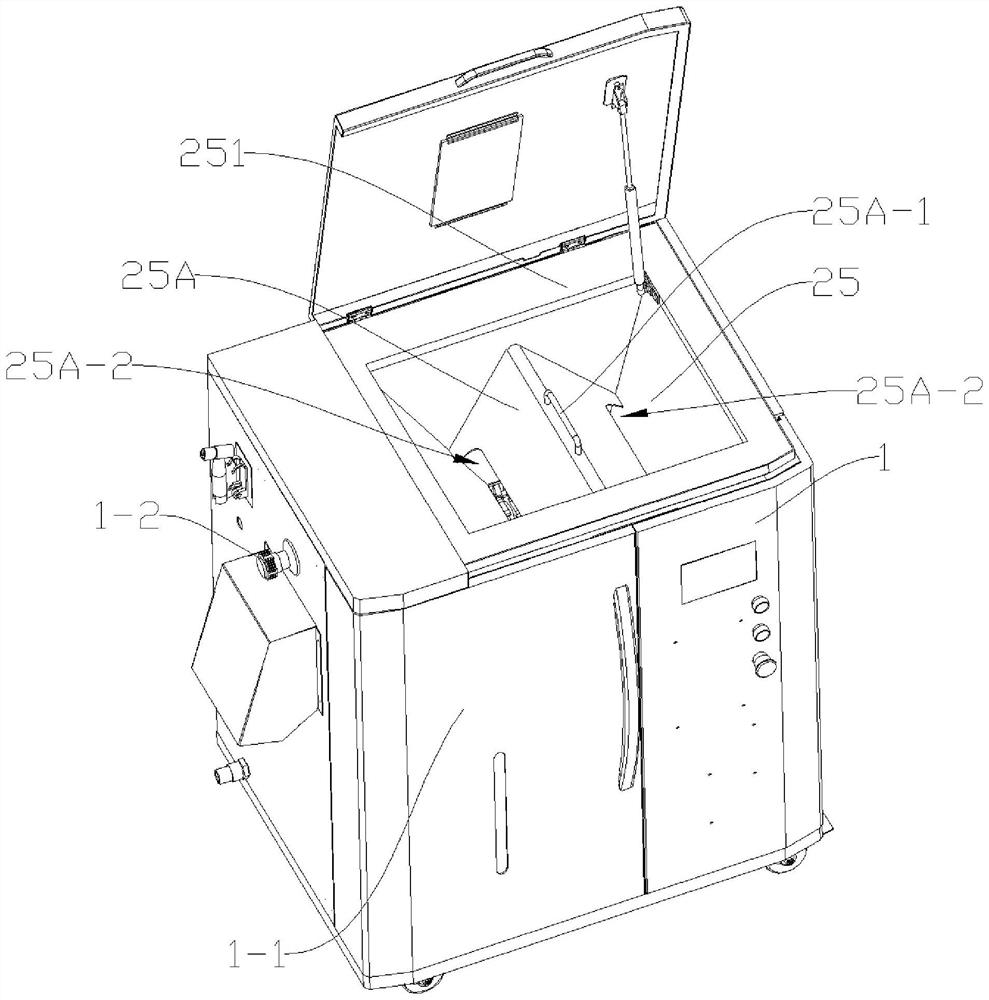

[0064] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine Figure 1-Figure 14 The accompanying drawings describe the present invention in further detail.

[0065] refer to figure 1 , figure 2 As shown, an intelligent comprehensive processing device for kitchen waste is characterized in that it includes a chassis 1, a crushing device 2, a solid-liquid separation device 3, an oil-water separation device 4, a deodorizing device 5, a centralized control module 6, and a chassis 1 There are a first chamber 1A and a second chamber 1B opposite to each other. The crushing device 2, the solid-liquid separation device 3, and the oil-water separation device 4 are sequentially installed in the first chamber 1A from top to bottom, and the deodorization device 5 is installed. On the inner wall of the second chamber 1B, the solid-liquid separation device 3 is deodorized by the deodorization device 5, the centralized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com