Quick-setting plugging material and preparation method thereof

A kind of plugging material, fast-setting technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of intermediate collapse, water seepage at the plugging, etc., to achieve high strength and improve anti-cracking ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

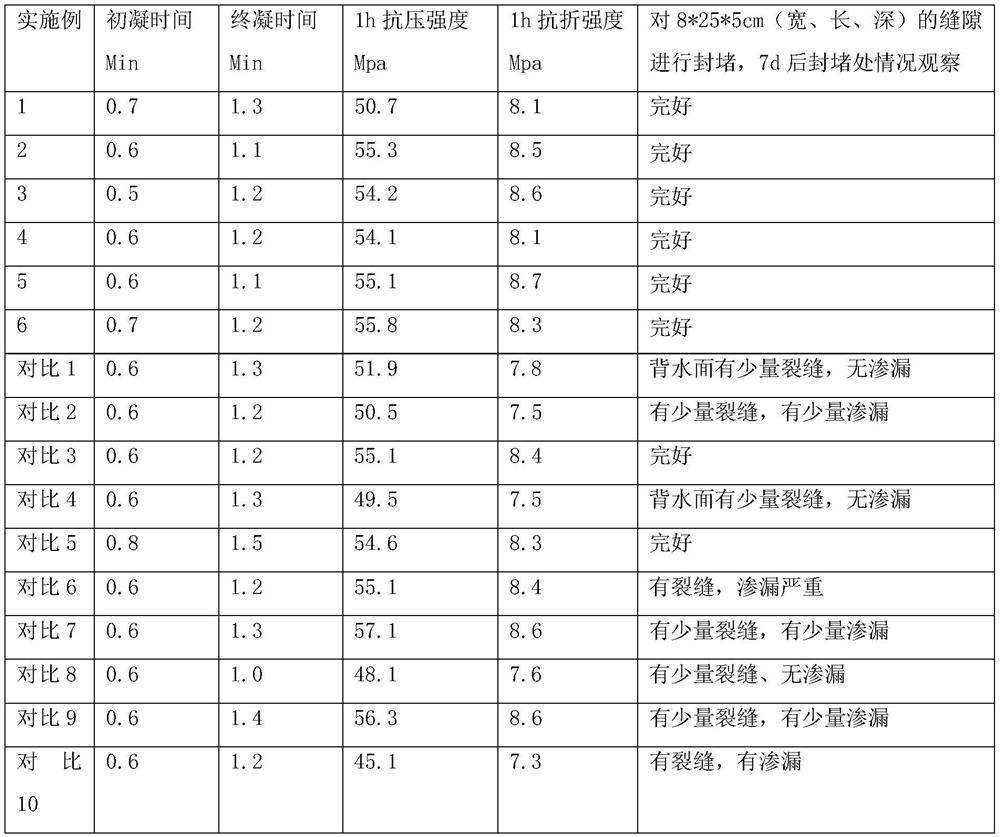

Examples

Embodiment 1

[0027] The present embodiment provides a quick-setting leakage plugging material, which comprises the following steps:

[0028] The first step, adding 72kg sulfoaluminate cement, 15kg Portland cement, 0.5kg hydroxyethyl cellulose, 1kg silica gel powder, 0.5kg polycarboxylate water reducer and 0.5kg calcium stearate into the mixing tank and stirring 15min;

[0029] The second step, the first step gains are added to the ball mill for ball milling for 3min;

[0030] The 3rd step, the second step gained and 5kg of emery and 5kg of quartz sand are added to the stirring tank and stirred for 20min, then the iron column that accounts for 2% of the volume of the mixture in the previous step is added to continue stirring for 3min, to obtain the plugging material;

[0031] Among them, the fineness of quartz sand is 80-100 mesh, the fineness of emery is 80 mesh, the length of iron column is 3mm, and the diameter is 0.5mm.

Embodiment 2

[0033] The present embodiment provides a quick-setting leakage plugging material, which comprises the following steps:

[0034] The first step, adding 73.5kg sulfoaluminate cement, 17.5kg Portland cement, 0.75kg hydroxyethyl cellulose, 1.5kg silica gel powder, 0.75kg polycarboxylate water reducer and 0.75kg calcium stearate to stir Stir in the tank for 17.5min;

[0035] The second step, the first step gained is added to the ball mill for ball milling for 4min;

[0036] In the third step, the second step gained and 6.5kg of emery and 6.5kg of quartz sand were added to the stirring tank and stirred for 22.5min, and then the iron column that accounted for 3.5% of the volume of the mixture in the previous step was added and continued to stir for 4min to obtain the plugging material;

[0037] Among them, the fineness of quartz sand is 90 mesh, the fineness of emery is 90 mesh, the length of iron column is 4mm, and the diameter is 0.75mm.

Embodiment 3

[0039] The present embodiment provides a quick-setting leakage plugging material, which comprises the following steps:

[0040] The first step, 75kg sulfoaluminate cement, 20kg Portland cement, 1kg hydroxyethyl cellulose, 2kg silica gel powder, 1kg polycarboxylate water reducer and 1kg calcium stearate are added in the mixing tank and stirred for 20min;

[0041] The second step, the first step gained is added to the ball mill for ball milling for 5min;

[0042] The 3rd step, the second step gained and 8kg of emery and 8kg of quartz sand are added to the stirring tank and stirred for 25min, then the iron column that accounts for 5% of the volume of the mixture in the previous step is added to continue stirring for 5min to obtain the plugging material;

[0043] Among them, the fineness of quartz sand is 100 mesh, the fineness of emery is 100 mesh, the length of iron column is 5mm, and the diameter is 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com