Preparation method of high-purity lauramidopropyl betaine

A lauryl amidopropyl betaine, high-purity technology, applied in the field of preparation of high-purity lauryl amidopropyl betaine, can solve the problems of the influence of finished products, high cost of multiple recrystallization, complicated purification process, etc., to achieve The effect of reducing impurities, the method is simple and easy to operate, and the steps are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

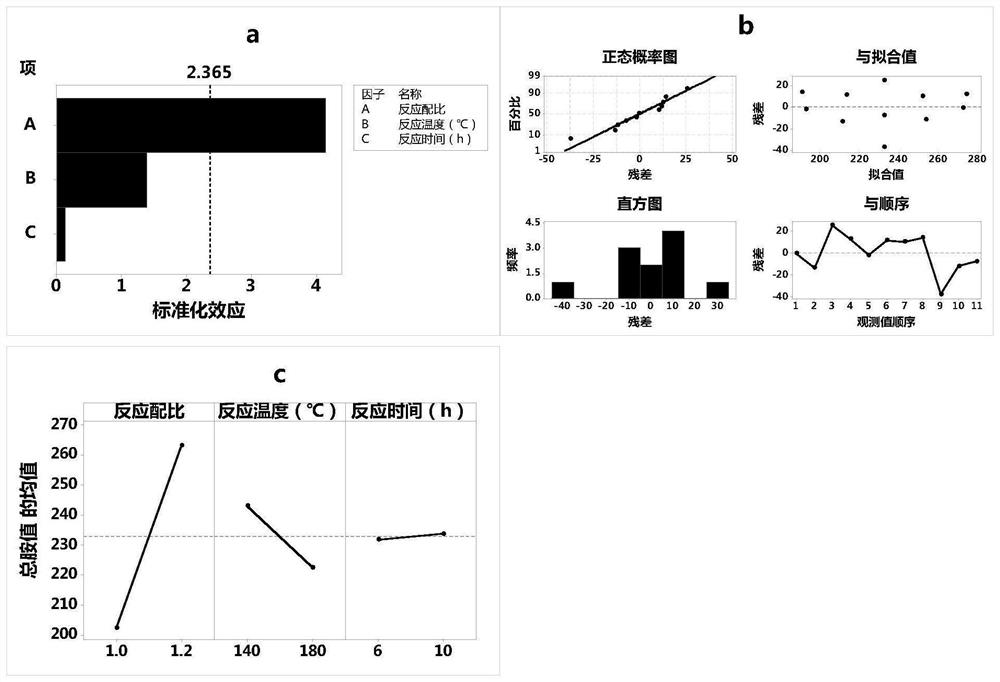

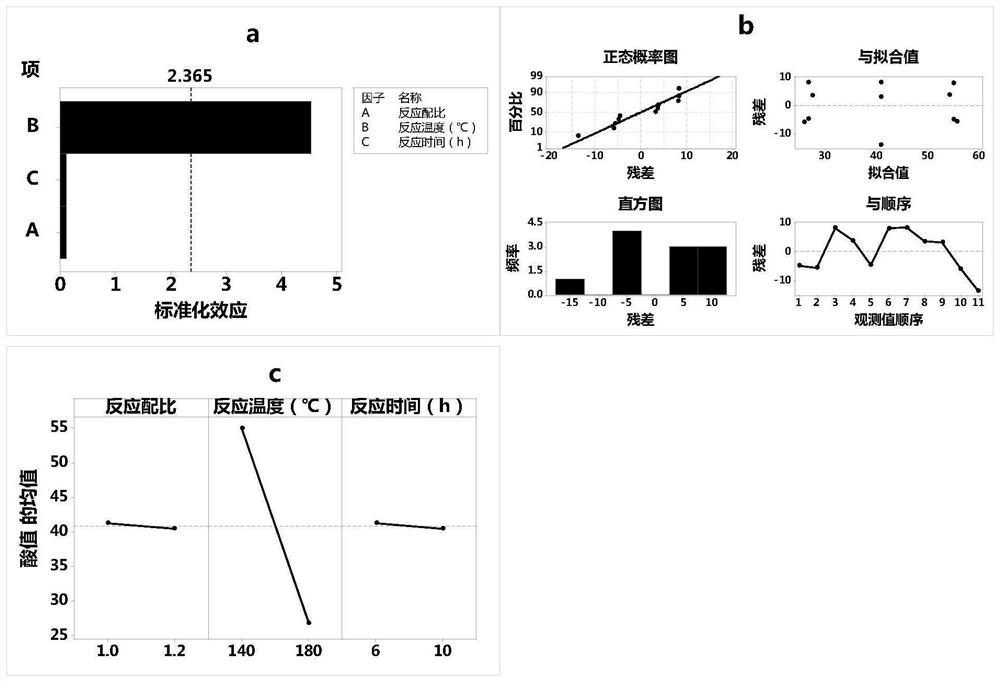

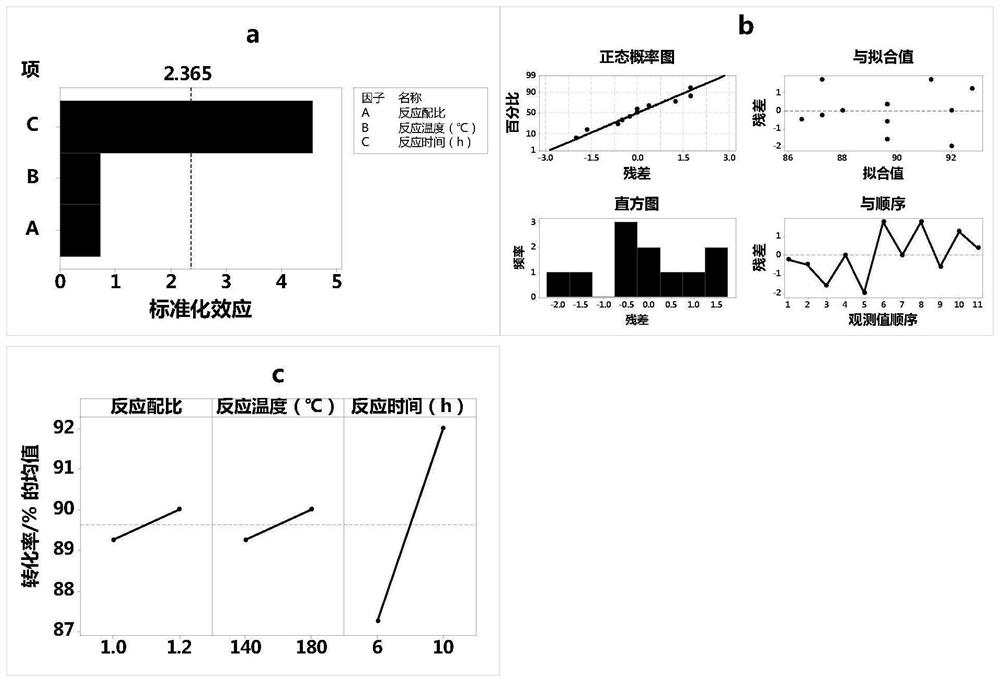

Image

Examples

Embodiment

[0040] A preparation method of high-purity lauroamidopropyl betaine, comprising the following steps:

[0041] (1) 20 g of lauric acid was weighed into a three-necked flask, and heated to 70° C. to dissolve completely.

[0042] (2) Start stirring at a stirring speed of 400 r / min, and slowly add 13.445 ml of DMAPA.

[0043] (3) Pass N under stirring 2 After 15 minutes, stop ventilation.

[0044] (4) Keep the stirring speed at 400 r / min, raise the temperature to 180 °C, stop the reaction after 10 h, and cool the product to 70 °C.

[0045] (5) Transfer the sample to a 250ml separating funnel, successively add 50ml ethyl acetate and 10ml 5% sodium chloride aqueous solution by mass, shake for 1min, stand for 10min and remove the lower layer liquid.

[0046] (6) Take the upper layer liquid, repeat step (5) twice, and transfer the sample obtained by three extractions to a 250ml rotary evaporation flask.

[0047] (7) Turn on the rotary steaming, the temperature is 70°C, the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com