Nucleating agent composition for transparent polypropylene, application of nucleating agent composition and polypropylene composition

A technology of transparent polypropylene and composition, applied in the field of plastics, can solve the problems of low precipitation, limited compatibility of polypropylene, easy generation of vacuum pores, etc., and achieve the effects of wide processing window, excellent dispersibility, and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

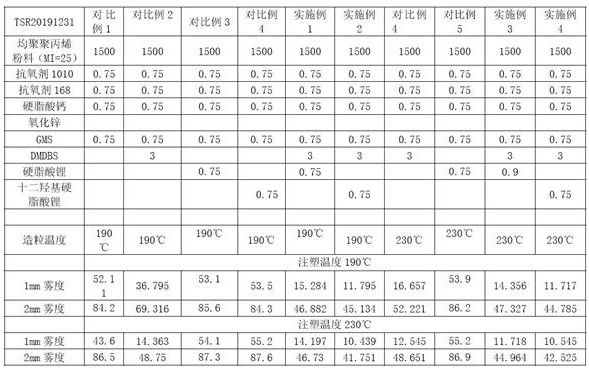

Examples

Embodiment

[0040] Taking polypropylene material as the base material, the parts by weight of each component are as follows:

[0041] The polypropylene material: 100 parts,

[0042] The main antioxidant is 0.001-0.2 parts,

[0043] The auxiliary antioxidant is 0.001-0.2 parts,

[0044] Acid scavenger is 0.01-0.3 parts,

[0045] The nucleating agent DMDBS is 0.15-0.5 parts,

[0046] The transparency modifier is 0.05-0.5 parts.

[0047] Antistatic agent is 0.03-0.2 parts

[0048] During preparation, the aforementioned components were added to a high-speed kneader, stirred and mixed for 5 minutes, and then mixed and granulated in a twin-screw extruder. The extrusion and granulation temperatures were set at 190°C and 230°C, respectively. Then, the polypropylene resin particles obtained by granulation were injected with standard samples at 190°C and 230°C for testing, and the haze values of the standard samples obtained at different molding temperatures were compared. The lower the haze ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com