High-cleanliness gasoline additive and preparation method thereof

A gasoline additive and additive technology, which is applied in fuel additives, mechanical equipment, petroleum industry, etc., can solve the problems that the engine does not fully utilize the fuel, does not fundamentally promote the combustion of fuel, and cannot be better applied, etc. NOx and solid particulate emissions, obvious fuel-saving effect, and carbon monoxide reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

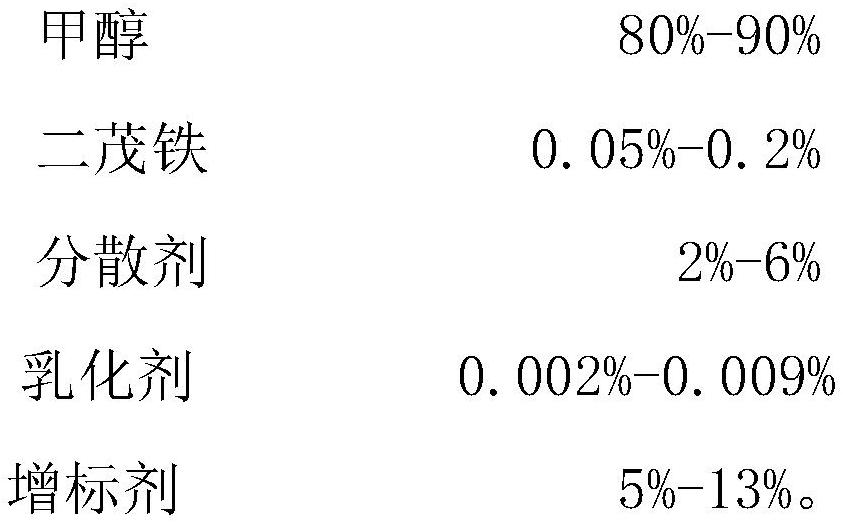

[0023] A specific embodiment of a high-clean gasoline additive of the present invention, the additive is prepared from the following raw materials by mass:

[0024]

[0025] A preparation method of high-clean gasoline additive is characterized in that: comprises the following steps:

[0026] Step 1: Weigh methanol, ferrocene and dispersant according to parts by weight, mix them, and perform cyclic stirring to obtain a first mixed solution;

[0027] Step 2: Weigh the emulsifier by weight, mix and stir the emulsifier with the first mixed solution for 45min to obtain the second mixed solution;

[0028] Step 3: Weigh the standard increasing agent in parts by weight, stir the standard increasing agent and the second mixed solution at 30° C. for 20 minutes, and mix them evenly to prepare a finished product.

[0029] In this embodiment, the mixing temperature in step 1 is 30°C.

[0030] In this embodiment, the time of circulating stirring described in step 1 is 1h.

[0031] In ...

Embodiment 2

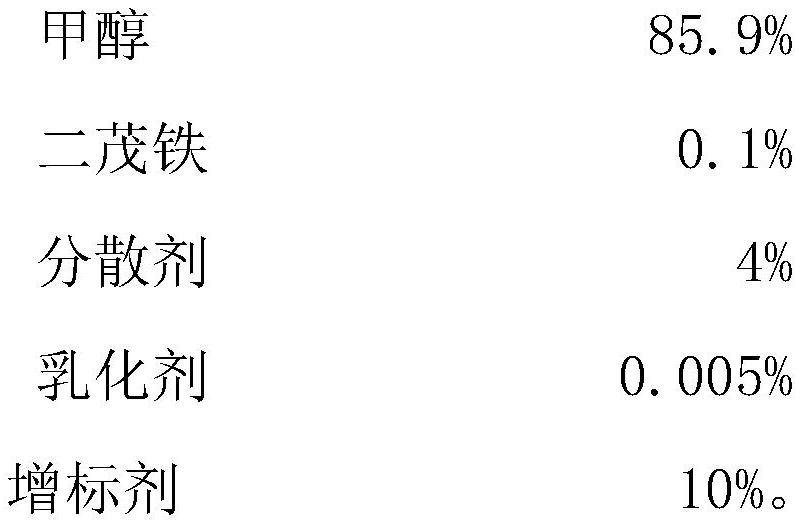

[0035] A specific embodiment of a high-clean gasoline additive of the present invention, the additive is prepared from the following raw materials by mass:

[0036]

[0037] A preparation method of high-clean gasoline additive is characterized in that: comprises the following steps:

[0038] Step 1: Weigh methanol, ferrocene and dispersant according to parts by weight, mix them, and perform cyclic stirring to obtain a first mixed solution;

[0039] Step 2: Weigh the emulsifier by weight, mix the emulsifier with the first mixed solution and stir for 50min to obtain the second mixed solution;

[0040] Step 3: Weigh the standard increasing agent in parts by weight, stir the standard increasing agent and the second mixed solution at 32° C. for 25 minutes, and mix them uniformly to prepare a finished product.

[0041] In this embodiment, the mixing temperature in step 1 is 33°C.

[0042] In this embodiment, the time of circulating stirring described in step 1 is 1.2h.

[0043...

Embodiment 3

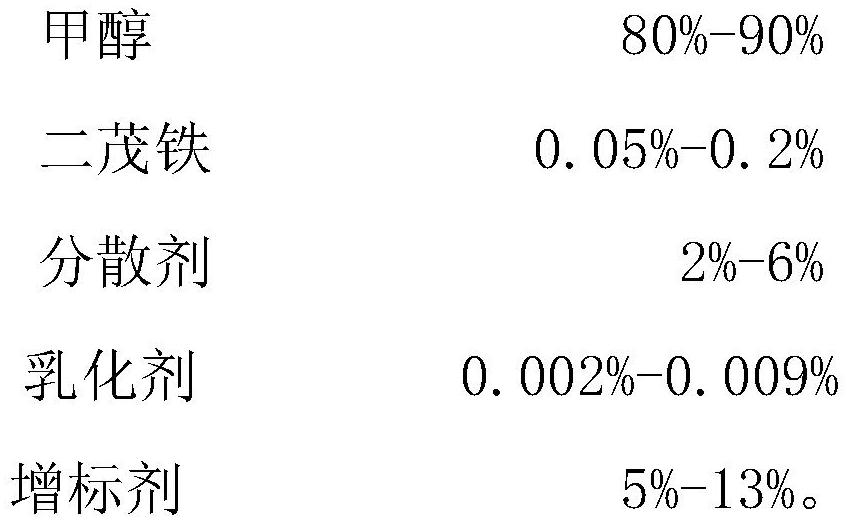

[0047] A specific embodiment of a high-clean gasoline additive of the present invention, the additive is prepared from the following raw materials by mass:

[0048]

[0049] A preparation method of high-clean gasoline additive is characterized in that: comprises the following steps:

[0050] Step 1: Weigh methanol, ferrocene and dispersant according to parts by weight, mix them, and perform cyclic stirring to obtain a first mixed solution;

[0051] Step 2: Weigh the emulsifier by weight, mix the emulsifier with the first mixed solution and stir for 55min to obtain the second mixed solution;

[0052] Step 3: Weigh the standard increasing agent in parts by weight, stir the standard increasing agent and the second mixed solution at 35° C. for 30 minutes, and mix them evenly to prepare a finished product.

[0053]In this embodiment, the mixing temperature in step 1 is 35°C.

[0054] In this embodiment, the time of circulating stirring described in step 1 is 1.5h.

[0055] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com