Intelligent drying control system of grain dryer

A grain dryer and drying control technology, applied in drying safety system, general control system, control/regulation system, etc., can solve the problem of low controllability and automation of equipment, independent and incompatible control systems, increase drying Operation complexity and other issues, to achieve the effect of reliable performance, high degree of automation and control precision, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

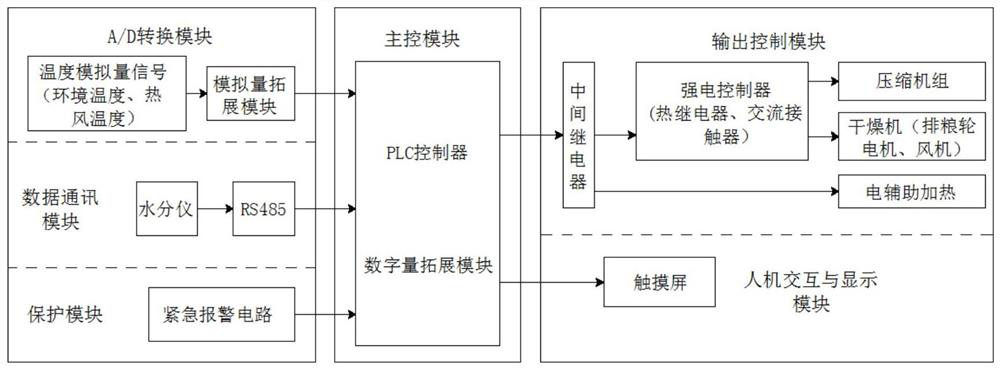

[0020] see figure 1 This embodiment provides an intelligent drying control system for a grain dryer, including a main control module, an A / D conversion module, a data communication module, a protection module, an output control module, and a human-computer interaction and display module. The main control module It includes PLC controller and digital expansion module and completes tasks including signal acquisition, data processing and system monitoring. A / D conversion module realizes analog signal input including ambient temperature and hot air temperature, and signal A / D Convert and connect with the main control module, the data communication module transmits the moisture signal detected by the grain moisture meter in the grain dryer to the main control module through RS485 communication, and the protection module transmits the alarm information generated by the electrical equipment in the grain dryer through the emergency alarm circuit. It is transmitted to the main control ...

Embodiment 2

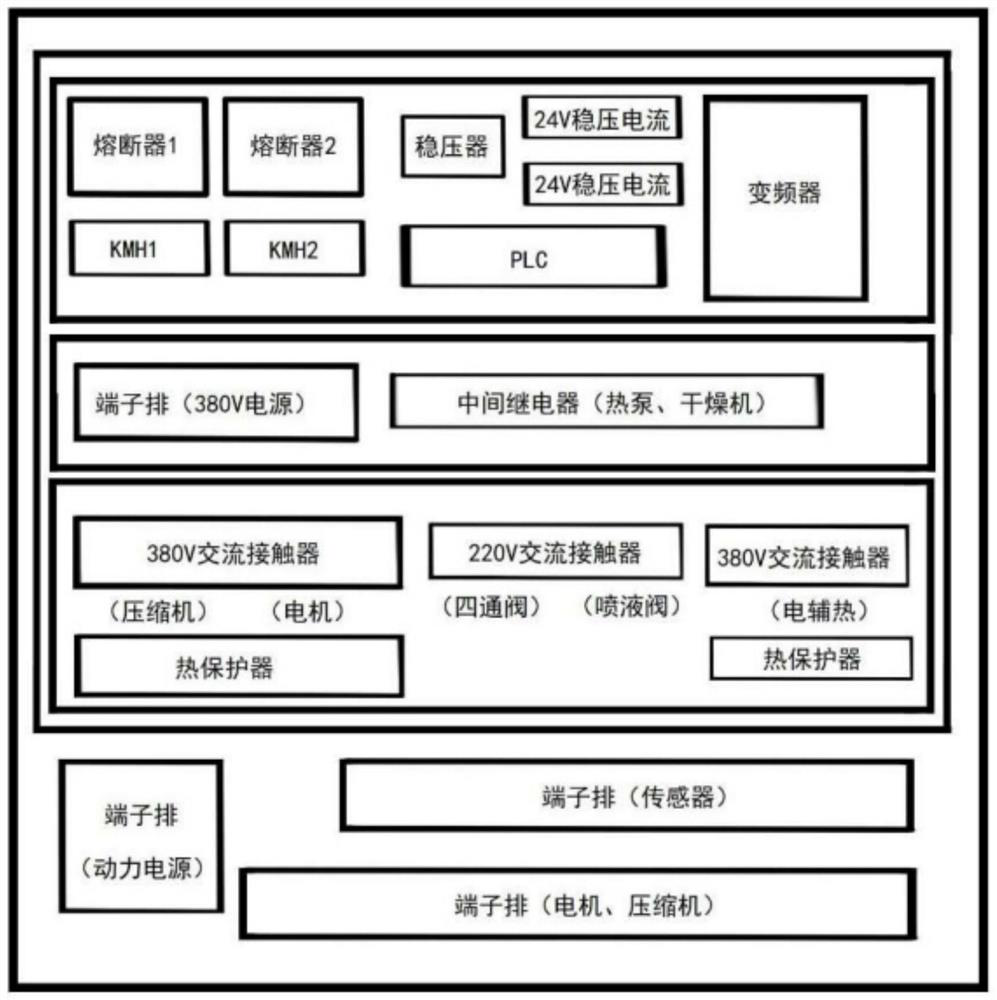

[0029] see figure 2 , image 3 , this embodiment provides an electrical control cabinet of an intelligent drying control system for a grain dryer. The electrical control cabinet is part of a main control area, a buffer area, an execution area and a system transfer area, and the four areas are connected by a wire trough. Separate and reserve cooling space, the four areas are:

[0030] The top layer of the electrical control cabinet is the main control area. The main control area is composed of main fuse, main relay, 24V regulated power supply, PLC controller and inverter. It is the core area of the entire control system and is responsible for the power supply and control algorithm of the control system. the operation of the main control area, the instructions sent by the main control area are handed over to other areas for execution;

[0031] The second layer of the control cabinet is the buffer zone from the top to the bottom. The buffer zone is composed of the shunt term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com