Method for measuring surface roughness of metal

A metal surface and roughness technology, applied in the field of metal surface roughness measurement, can solve the problems of unhealthy and dangerous operators, low measurement efficiency, low measurement accuracy, etc., achieve good operability and realize the effect of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

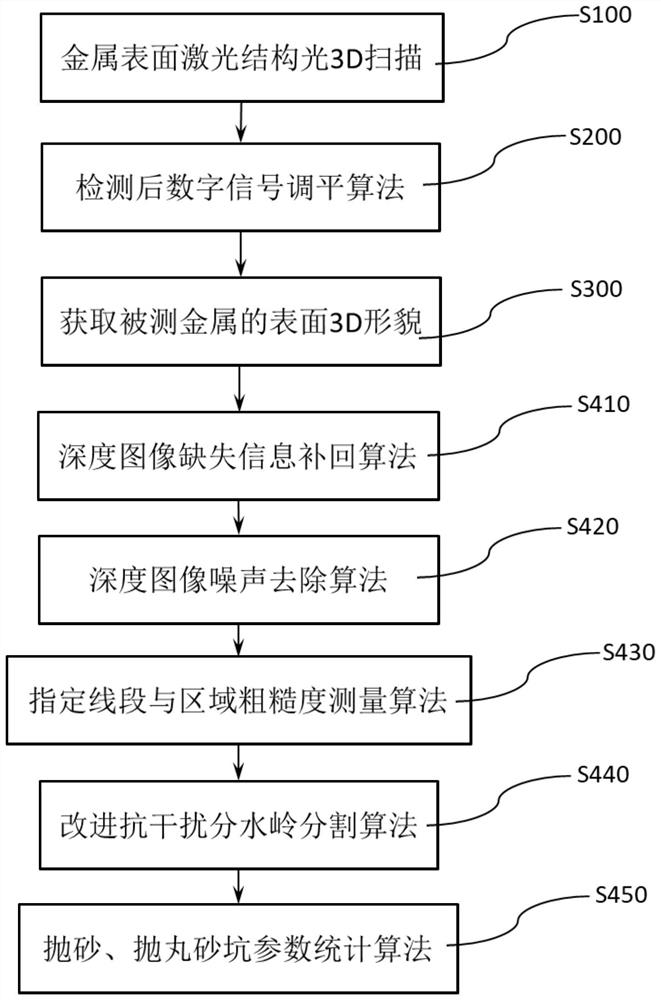

[0070] Below in conjunction with accompanying drawing, structure principle and working principle of the present invention are described in detail:

[0071] In the machine vision technology of the prior art, there are many ways of 3D vision, but relatively speaking, laser structured light vision is a 3D vision method with high precision and good reliability. Based on this background, the present invention adopts laser structured light. The metal surface is scanned visually, and the metal surface roughness measurement is realized through the algorithm of many key links from the depth signal to the roughness measurement.

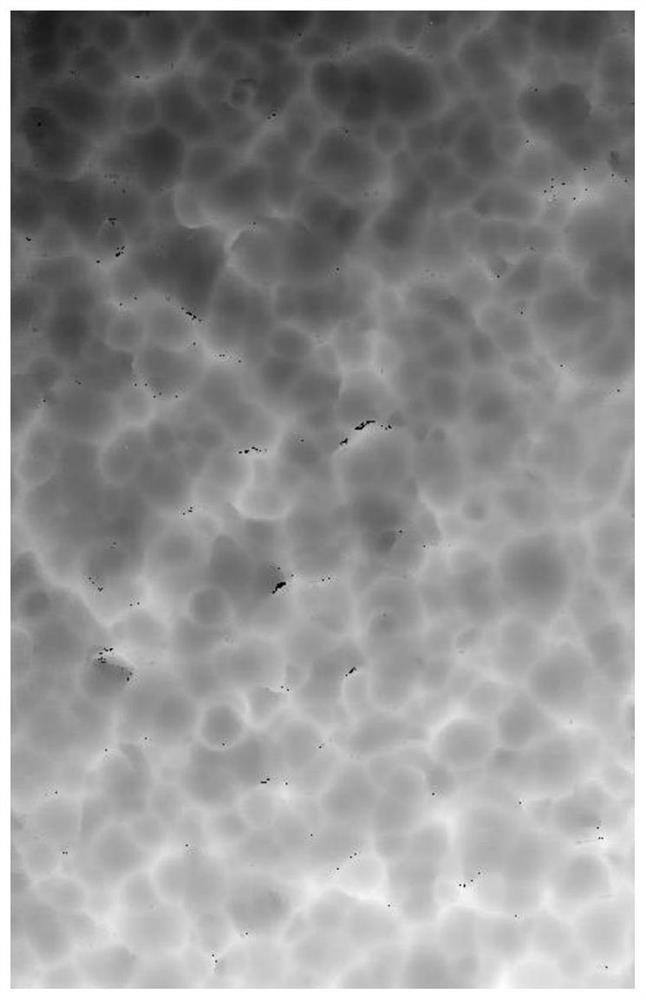

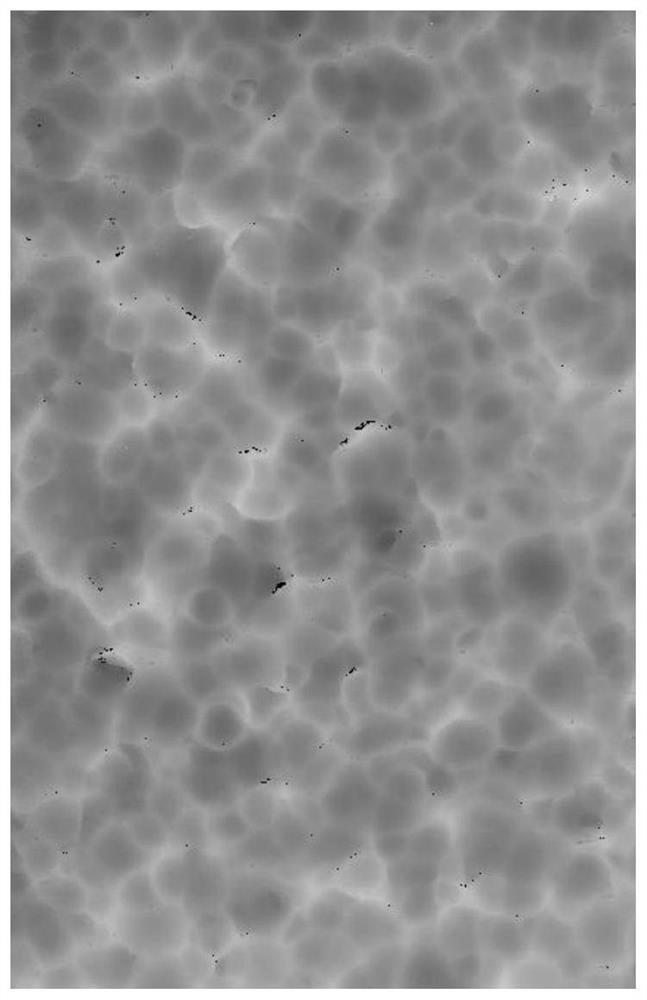

[0072] The method for measuring the roughness of the metal surface of the present invention adopts a laser structured light 3D vision system. First, the vision system is used to level the measured plane according to a leveling algorithm, and then the metal surface is scanned and imaged to obtain the 3D shape of the metal surface. Then, the roughness of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com