Epitaxial structure of red and yellow GaAs diode and preparation method thereof

An epitaxial structure and diode technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of insufficient simplification of epitaxial structure and epitaxial processing technology, affecting LED luminous brightness, affecting light reflection, etc. , to achieve the effects of low production cost, simplified epitaxial structure and epitaxial processing technology, and increased spontaneous emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

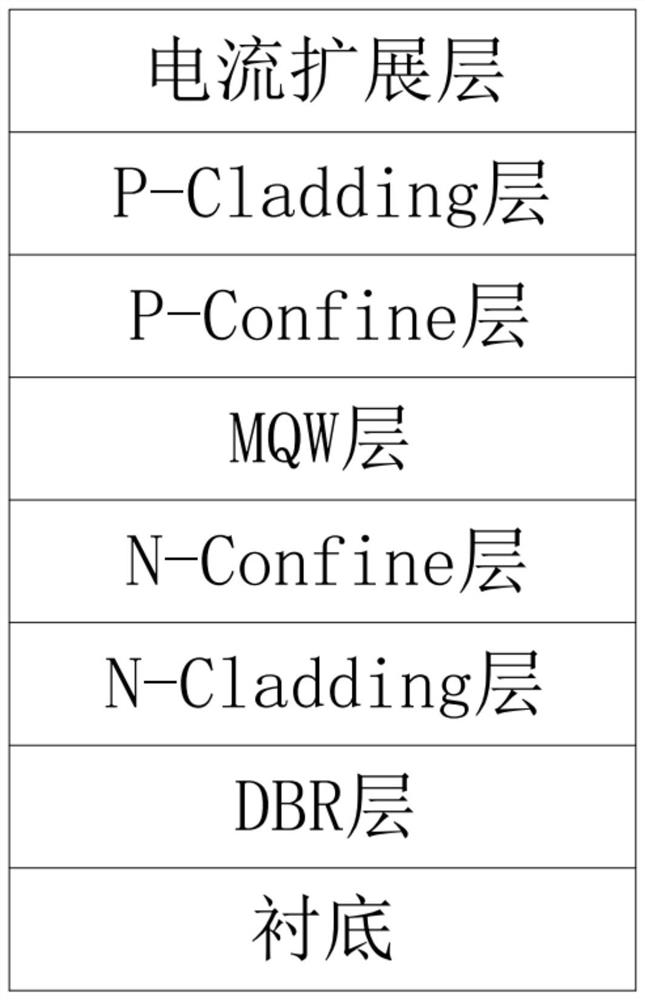

[0035] like figure 1 shown, figure 1 It is the epitaxial structure of the traditional red-yellow GaAs diode. Multiple quantum well layer (Multiple Quantum Well, MQW layer for short), P-type confinement layer (P-Confine layer), P-type cladding layer (P-Cladding layer) and current spreading layer, the existence of N-type cladding layer not only makes the epitaxial structure And the epitaxial processing technology is not simple enough, and because the travel of photons to the Bragg reflector is increased, the reflection of light by the Bragg reflector is affected, and then the luminous brightness of the LED is affected.

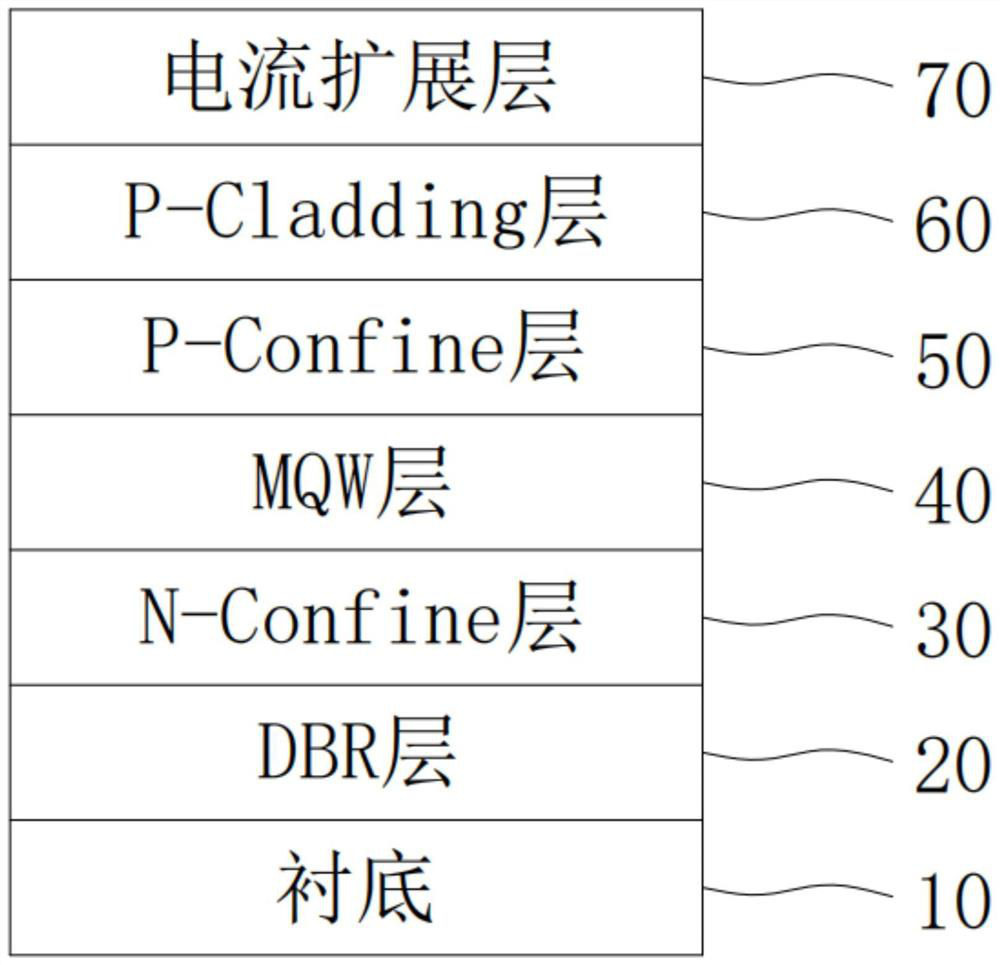

[0036] like figure 2 As shown, an embodiment of the present invention provides an epitaxial structure of a red-yellow GaAs diode. The epitaxial structure includes: a substrate 10, a Bragg mirror 20 and an N-type confinement layer 30 that are sequentially grown upward on the substrate 10. , the multiple quantum well layer 40, the P-type confinement layer 50, ...

Embodiment 2

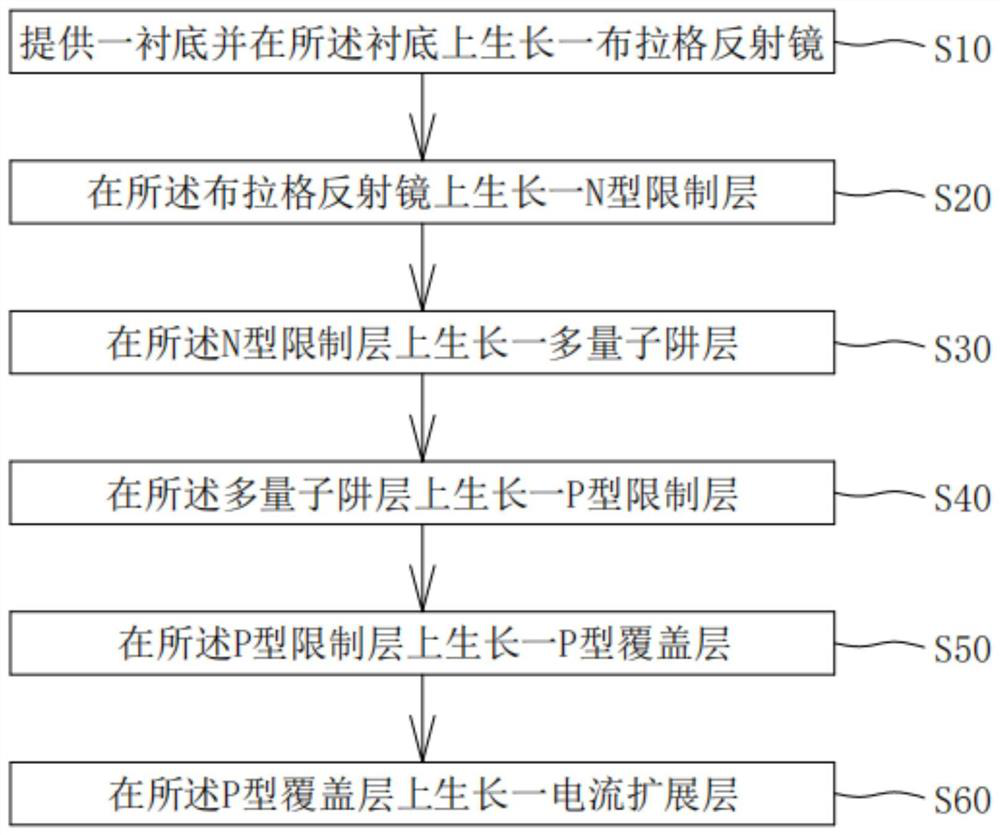

[0044] Please refer to image 3 , the second embodiment of the present invention provides a method for preparing an epitaxial structure of a red-yellow GaAs diode, which is used for preparing the epitaxial structure of the red-yellow GaAs diode in the above-mentioned first embodiment, and the preparation method includes steps S10-S60 :

[0045] S10, providing a substrate and growing a Bragg mirror on the substrate;

[0046] S20, growing an N-type confinement layer on the Bragg mirror;

[0047] S30, growing a multiple quantum well layer on the N-type confinement layer;

[0048] S40, growing a P-type confinement layer on the multiple quantum well layer;

[0049] S50, growing a P-type capping layer on the P-type confinement layer;

[0050] S60, growing a current spreading layer on the P-type cladding layer;

[0051] In the embodiment of the present invention, the N-type confinement layer is an AlGaInP layer, the multiple quantum well layer includes an alternately grown GaInP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com