Oily sewage treatment method and system

A treatment method and a treatment system technology, applied in the field of sewage treatment, can solve problems such as high residual oil content and poor treatment effect, and achieve the effects of improved treatment speed, good environmental friendliness, and reasonable process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Oily Sewage Treatment Test

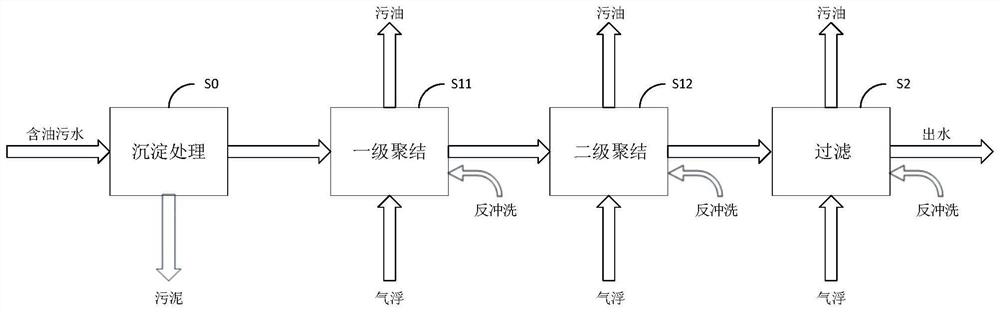

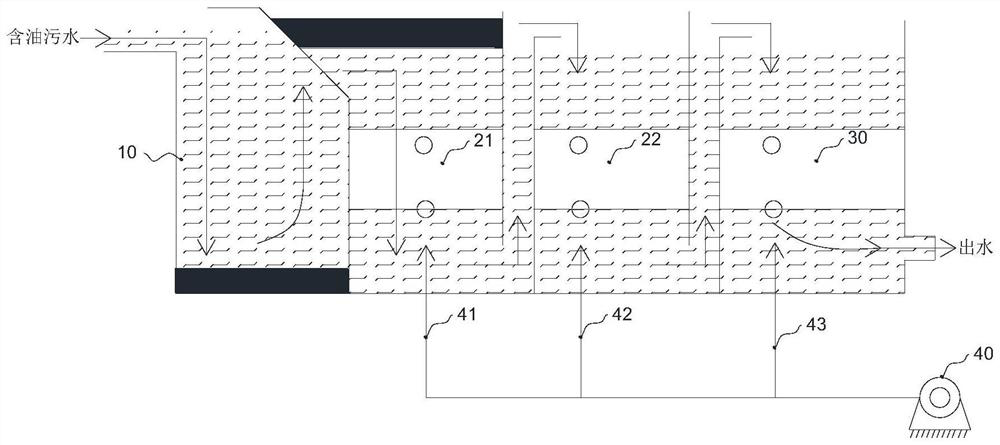

[0095] Adopt the oily sewage treatment method described in this application to carry out the treatment test to the oily sewage, take the oily sewage after the three-phase separation of the oil field as the test object, the color of the sewage is black, and the oil content before the treatment is about 2000ppm. image 3 shown. The processing procedure includes the following steps:

[0096] The above-mentioned oily sewage is subjected to preliminary precipitation to remove large particles of sand and gravel; then it enters the first-stage coalescing component, and passes through the first-stage coalescing filter element (under the action of dissolved air water) for coalescing + air flotation separation; The coalescence component is further coalesced + air flotation separation through the secondary coalescing filter element (under the action of dissolved air and water); finally, it is passed into the filter component, and filtered + air flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com