Acidifying corrosion inhibitor for formation acidification blockage removal and preparation method thereof

A technology for acidizing corrosion inhibitors and formations, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of high corrosion inhibitor cost and low corrosion inhibition rate, and achieve high corrosion inhibition effect. , good effect, less dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

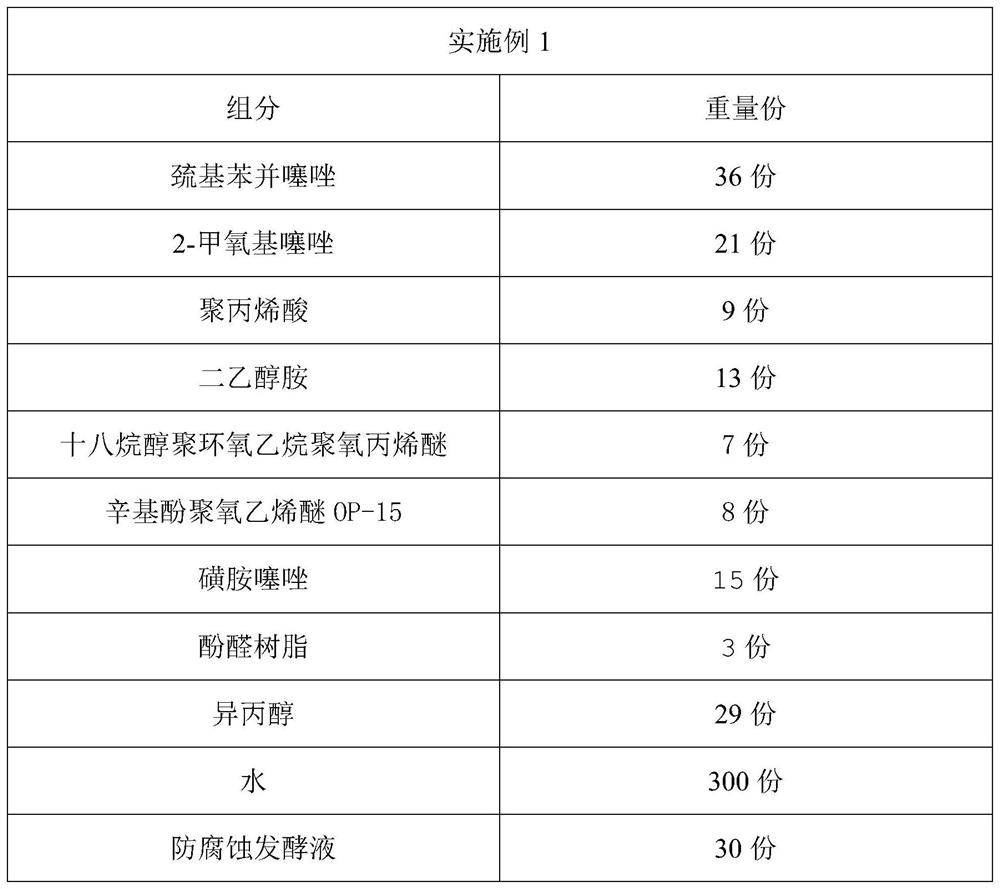

Embodiment 1

[0030] as Figure 1 As shown, the present invention provides an acidification inhibitor for formation acid deblocking, compatibility with formation deblocking agent to play a role in efficient acidification corrosion inhibition. Acidification inhibitor of the present invention includes components of the following weight, 36 parts of mercaptobenzothiazole, 2-methoxythiazole 21 parts, polyacrylic acid 9 parts, diethanolamine 13 parts, octadecanol polyethylene oxide polyoxypropylene ether 7 parts, octylphenol polyoxyethylene ether OP-15 8 parts, sulfonamide thiazole 15 parts, phenolic resin 3 parts, isopropanol 29 parts, water 300 parts and anti-corrosion fermentation liquid 30 parts.

[0031] The preparation method of the anti-corrosion fermentation liquid comprises the following steps, (1) the oyster powder, corn germ meal and bran crushed with peptone, sugarcane molasses and monocrystalline rock sugar mixed, water is added to the mixture to form a mixture; (2) according to the mass...

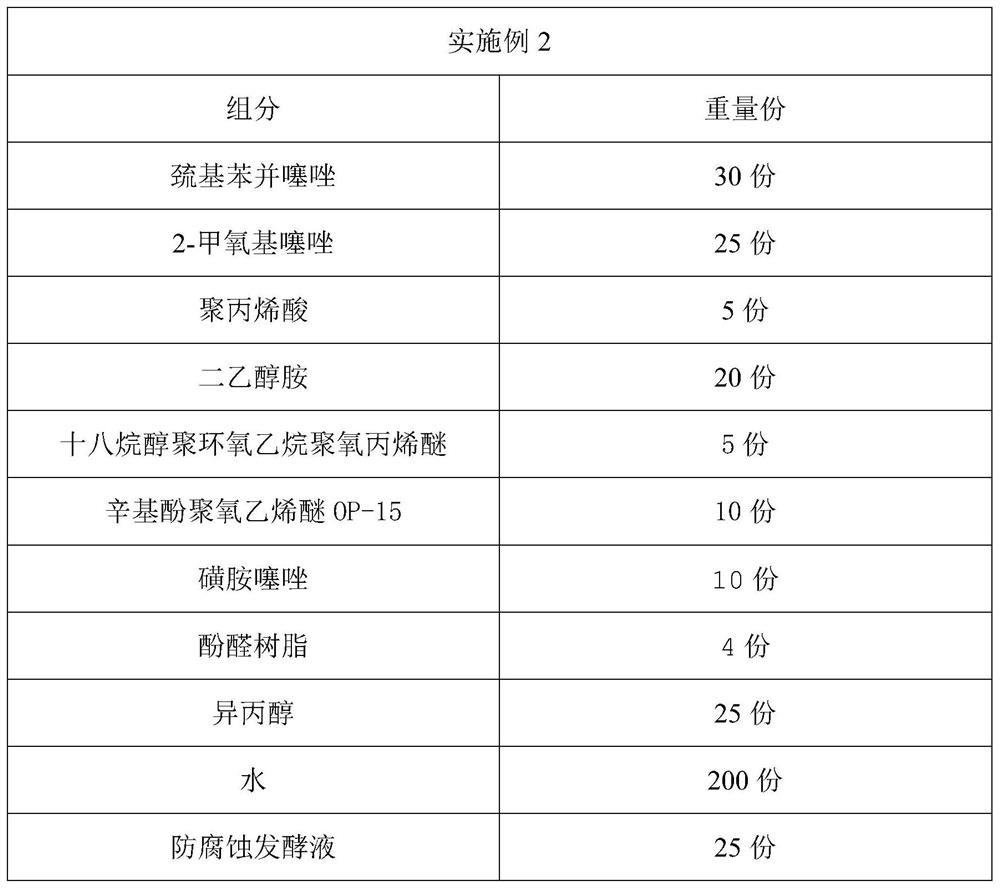

Embodiment 2

[0035] as Figure 2 As shown, the present invention provides an acidification inhibitor for formation acid deblocking, compatibility with formation deblocking agent to play a role in efficient acidification corrosion inhibition. Acidification inhibitor of the present invention includes components of the following weight, 30 parts of mercaptobenzothiazole, 25 parts of 2-methoxythiazole, 5 parts of polyacrylic acid, 20 parts of diethanolamine, 5 parts of octacol polyethylene oxide polyoxypropylene ether, octylphenol polyoxyethylene ether OP-15 10 parts, sulfonamide thiazole 10 parts, 4 parts of phenolic resin, 25 parts of isopropanol, 200 parts of water and 25 parts of anti-corrosion fermentation broth.

[0036] The preparation method of the anti-corrosion fermentation broth comprises the following steps, (1) the oyster powder, corn germ meal and bran crushed and mixed with peptone, sugarcane molasses and monocrystalline rock sugar, adding water to the mixture to form a mixture of li...

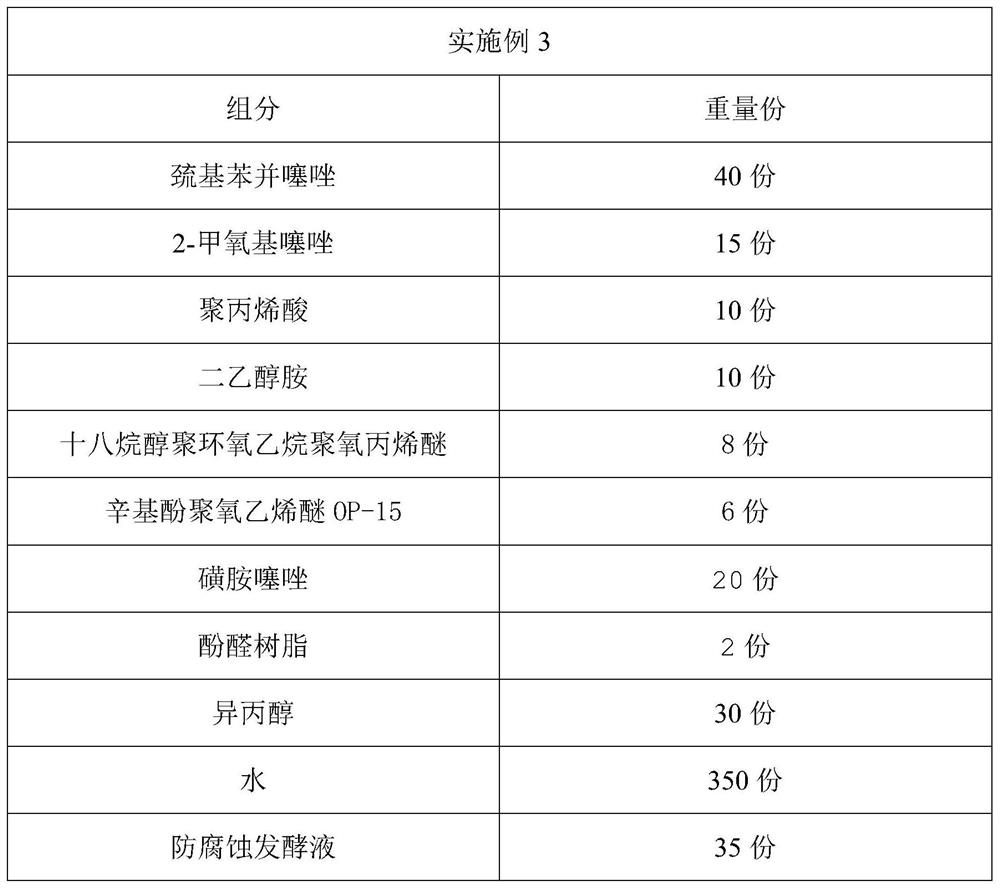

Embodiment 3

[0040] as Figure 3 As shown, the present invention provides an acidification inhibitor for formation acid deblocking, compatibility with formation deblocking agent to play a role in efficient acidification corrosion inhibition. Acidification inhibitor of the present invention includes components of the following weight, mercaptobenzothiazole 40 parts, 2-methoxythiazole 15 parts, polyacrylic acid 10 parts, diethanolamine 10 parts, octadecanol polyethylene oxide polyoxypropylene ether 8 parts, octylphenol polyoxyethylene ether OP-15 6 parts, sulfonamide 20 parts, phenolic resin 2 parts, isopropanol 30 parts, water 350 parts and anti-corrosion fermentation liquid 35 parts.

[0041]The preparation method of the anti-corrosion fermentation broth comprises the following steps, (1) the oyster powder, corn germ meal and bran crushed and mixed with peptone, sugarcane molasses and monocrystalline rock sugar, adding water to the mixture to form a mixture of liquid; (2) according to the inocu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com