Identification method of abnormal welding point of flat induction coil

A technology of induction coil and identification method, which is applied in the field of identification of abnormal welding points of plane induction coils, can solve problems such as research on surface defect detection, research on practical industrial problems, etc., and achieves the effect of high predictive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solutions implemented by the present invention will be clearly and completely described below with reference to the accompanying drawings in the examples of the present invention.

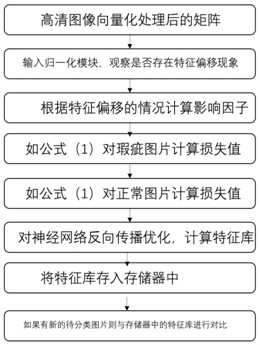

[0066] The idea of the present invention is to adjust the spatial distribution of the genuine image and the defective flat induction coil image by using the loss function based on the soft space angle, and to design a function for compensating the feature offset to solve the problem between the training data sample and the test data sample. The data distribution shift problem. This is the design motivation and design innovation of the present invention.

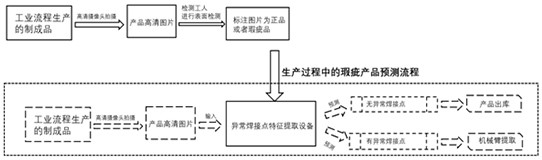

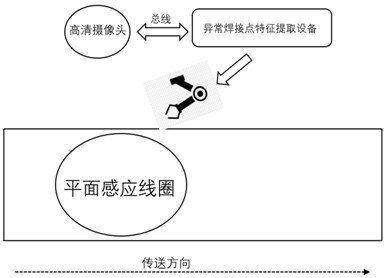

[0067] The identification and processing of abnormal welding points of flat induction coils is an important link in the quality inspection of flat induction coil production lines. In the actual quality inspection environment, the artificial quality inspection has a high rate of missed reports, a low quality inspection rate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com