Preparation method of AgNWs (at) LiG (at) PDMS sandwich structure flexible SERS substrate

A sandwich and flexible technology, used in cable/conductor manufacturing, electrical components, circuits, etc., to achieve the effects of controllable morphology and structure, good conductivity and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

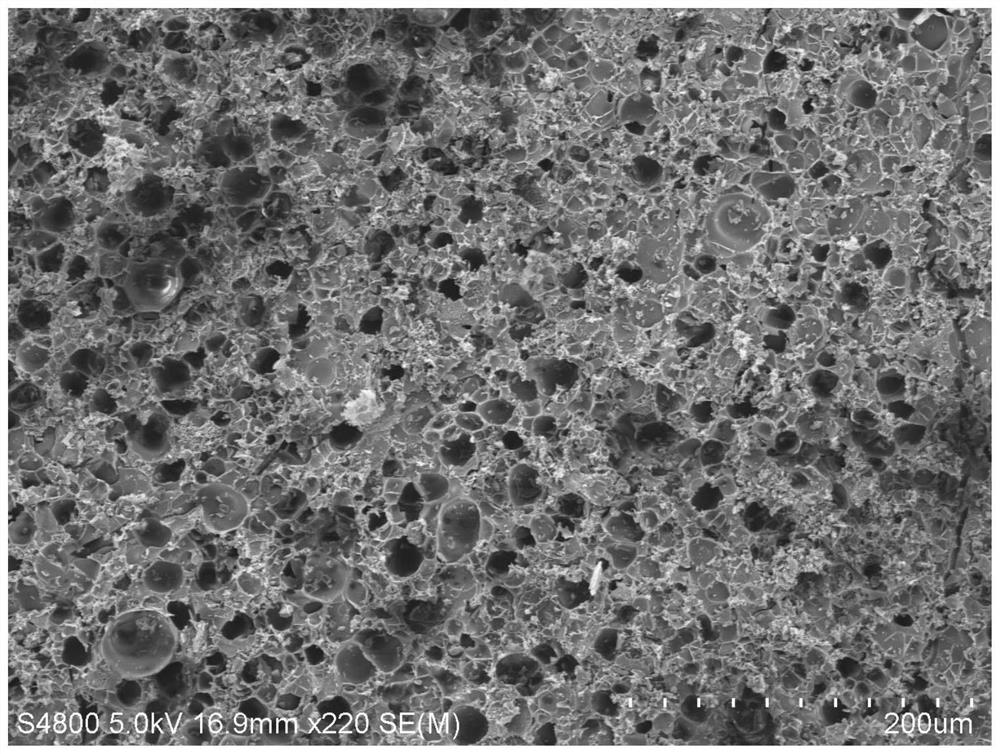

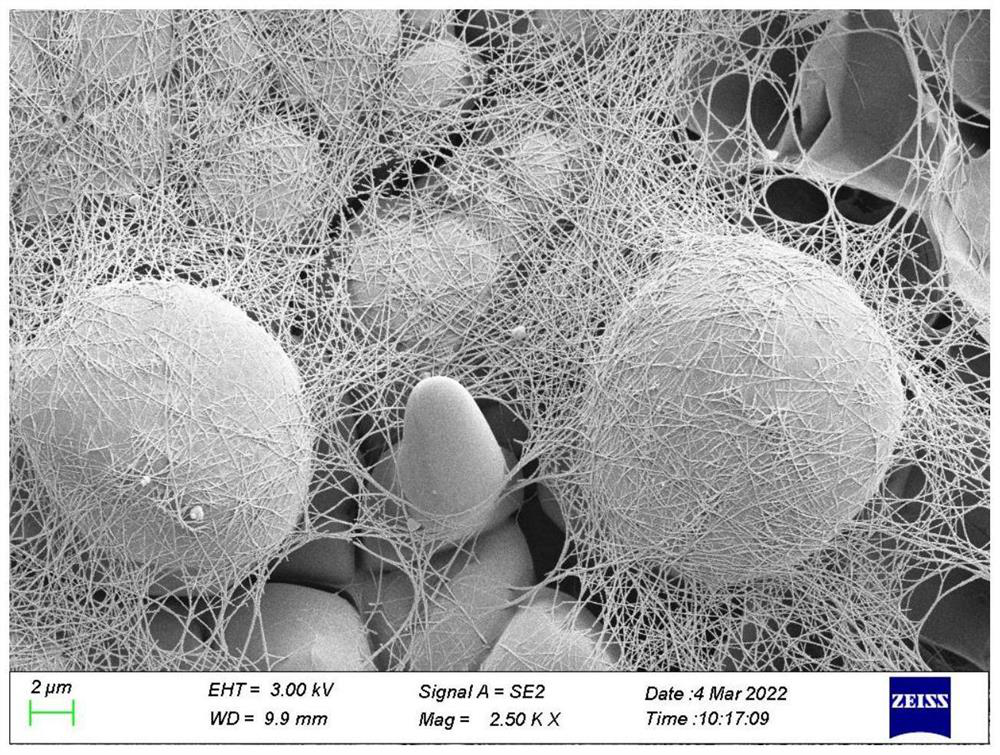

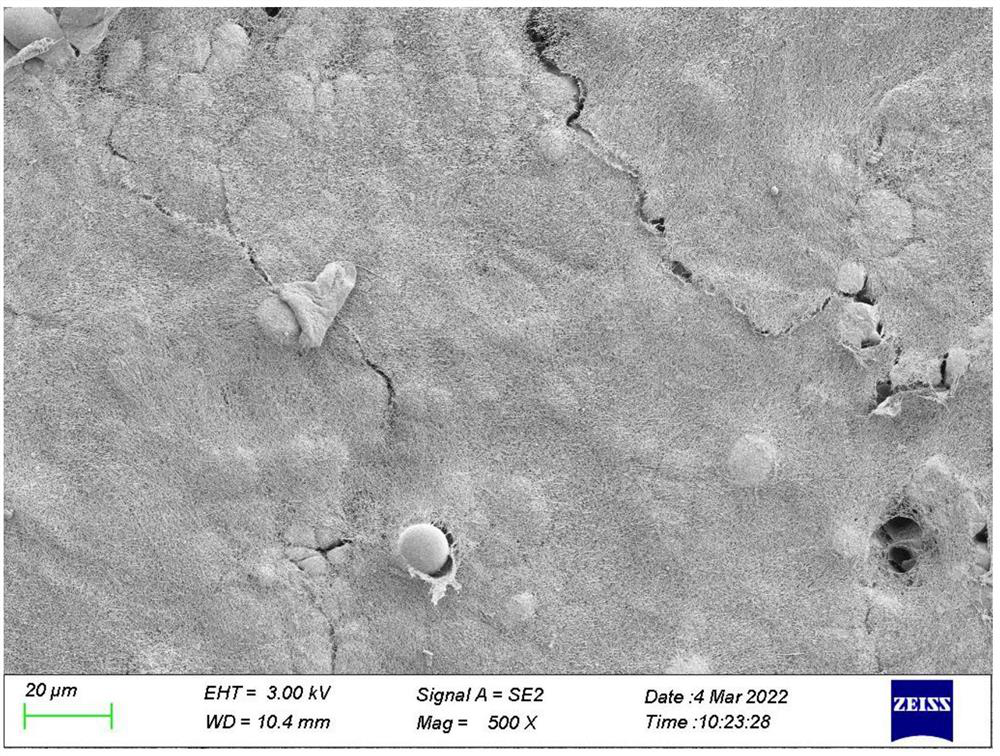

[0029] Set the parameters of the carbon dioxide laser as the laser emission power is 10%, the scanning frequency is 120KHZ, the scanning speed is 30mm / s, and the scanning thickness of the PI film is 100μm. C4D presets the rectangular shape with a size of 1.5cm*0.5cm to prepare a laser-induced Graphene, its scanning electron microscope picture is shown in figure 1 shown. Drop about 1mL of a mixture containing PDMS and curing agent (PDMS:curing agent=10:1w / w) on the surface of LiG and spread it on the surface of LiG, place the sample in a polytetrafluoroethylene container, put it in a vacuum oven, After repeating the debubbling operation about 6 times, it was transferred to a high-temperature oven at 130°C for curing for 1 hour, and the PI film was torn off, leaving the LiG@PDMS flexible SERS substrate with the PI film removed. Select AgNWS with a diameter of 25nm and a length of 25μm, disperse it in isopropanone suspension to prepare a solution with a concentration of 3mg / ml, ...

Embodiment 2

[0031] Set the parameters of the carbon dioxide laser as the laser emission power is 10%, the scanning frequency is 120KHZ, the scanning speed is 30mm / s, and the scanning thickness of the PI film is 100μm. C4D presets the rectangular shape with a size of 1.5cm*0.5cm to prepare a laser-induced Graphene, its scanning electron microscope picture is shown in figure 1 shown. Drop about 1mL of a mixture containing PDMS and curing agent (PDMS:curing agent=10:1w / w) on the surface of LiG and spread it on the surface of LiG, place the sample in a polytetrafluoroethylene container, put it in a vacuum oven, After repeating the debubbling operation about 6 times, it was transferred to a high-temperature oven at 130°C for curing for 1 hour, and the PI film was torn off, leaving the LiG@PDMS flexible SERS substrate with the PI film removed. Select AgNWS with a diameter of 25 nm and a length of 25 μm, disperse it in isopropanone suspension to prepare a solution with a concentration of 3 mg / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com