Silicon-carbon composite pole piece as well as preparation method and application thereof

A silicon-carbon composite and pole piece technology, which is applied to battery electrodes, structural parts, electrical components, etc., can solve problems such as conductive network failure, achieve high conductivity, improve manufacturability, and improve cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

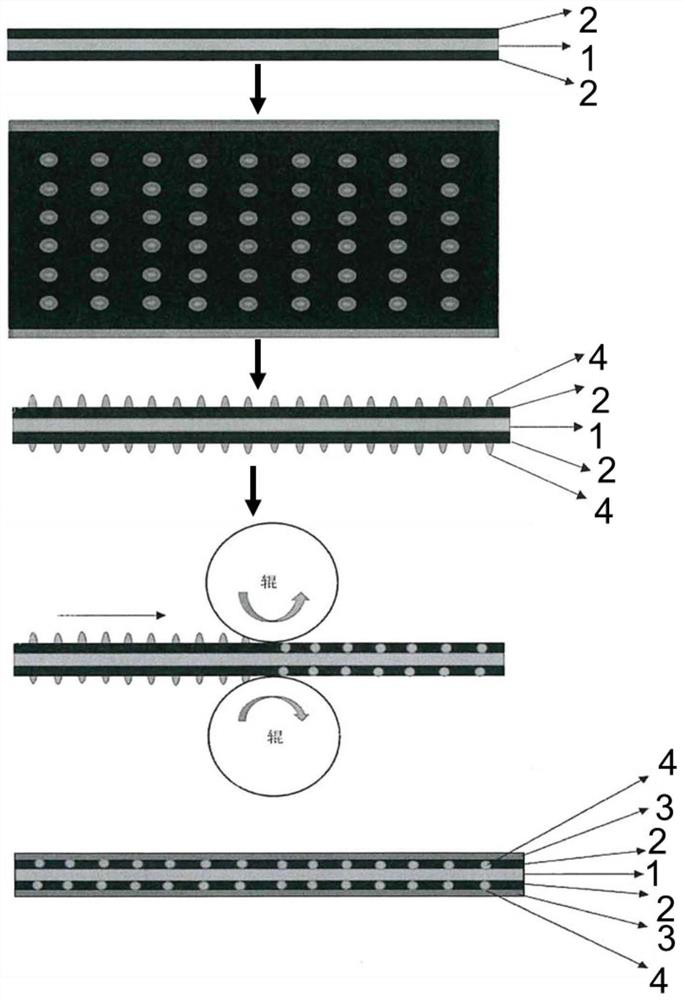

[0058] This embodiment provides a silicon-carbon composite pole piece, which includes a base body 1, a first conductive layer 2 and a second conductive layer 3 are stacked on both sides of the base body 1 in sequence, and the first conductive layer 2 is dispersed with silicon-carbon active layers. Substance 4, first conductive layer 2 and second conductive layer 3 independently comprise single-walled carbon nanotubes. The base 1 is made of copper foil with a thickness of 0.15 mm.

[0059] like figure 1 As shown, the preparation method of the above-mentioned silicon carbon composite pole piece is as follows:

[0060] (1) After mixing polyvinylidene fluoride, polyvinylpyrrolidone and N-methylpyrrolidone, perform a stirring for 300min to obtain a first glue solution, and then disperse single-wall carbon nanotubes with a diameter of 3nm in the first glue In the liquid, a vacuum stirring was performed for 300 min to obtain a conductive paste. The mass percentages of the component...

Embodiment 2

[0065] This embodiment provides a silicon-carbon composite pole piece, which includes a base body 1, a first conductive layer 2 and a second conductive layer 3 are stacked on both sides of the base body 1 in sequence, and the first conductive layer 2 is dispersed with silicon-carbon active layers. Substance 4, first conductive layer 2 and second conductive layer 3 independently comprise single-walled carbon nanotubes. The base 1 is made of copper foil with a thickness of 0.08 mm.

[0066] The preparation method of above-mentioned silicon carbon composite pole piece is as follows:

[0067] (1) After mixing polyvinylidene fluoride, polyvinylpyrrolidone and N-methylpyrrolidone, perform a stirring for 285min to obtain a first glue solution, and then disperse single-walled carbon nanotubes with a diameter of 0.8nm in the first glue In a glue solution, vacuum stirring was carried out for 285 minutes to obtain a conductive paste. The mass percentages of the components in the conduct...

Embodiment 3

[0072]This embodiment provides a silicon-carbon composite pole piece, which includes a base body 1, a first conductive layer 2 and a second conductive layer 3 are stacked on both sides of the base body 1 in sequence, and the first conductive layer 2 is dispersed with silicon-carbon active layers. Substance 4, first conductive layer 2 and second conductive layer 3 independently comprise single-walled carbon nanotubes. The base 1 is made of copper foil with a thickness of 0.1 mm.

[0073] The preparation method of above-mentioned silicon carbon composite pole piece is as follows:

[0074] (1) After mixing polyvinylidene fluoride, polyvinylpyrrolidone and N-methylpyrrolidone, perform a stirring for 315min to obtain a first glue solution, and then disperse single-walled carbon nanotubes with a diameter of 4nm in the first glue In the glue solution, a vacuum stirring for 315min is performed to obtain a conductive paste. The mass percentages of the components in the conductive past...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com