Anti-winding pickup device and harvester

An anti-entanglement and pick-up roller technology, which is applied to harvesters, loaders, agricultural machinery and implements, etc., can solve the problems of easy grass entanglement, limited anti-entanglement effect, and high breakage rate in sugarcane harvesting, so as to reduce sugarcane falling. The effect of reducing fruit drop rate and loss rate, increasing harvest rate and sugar yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

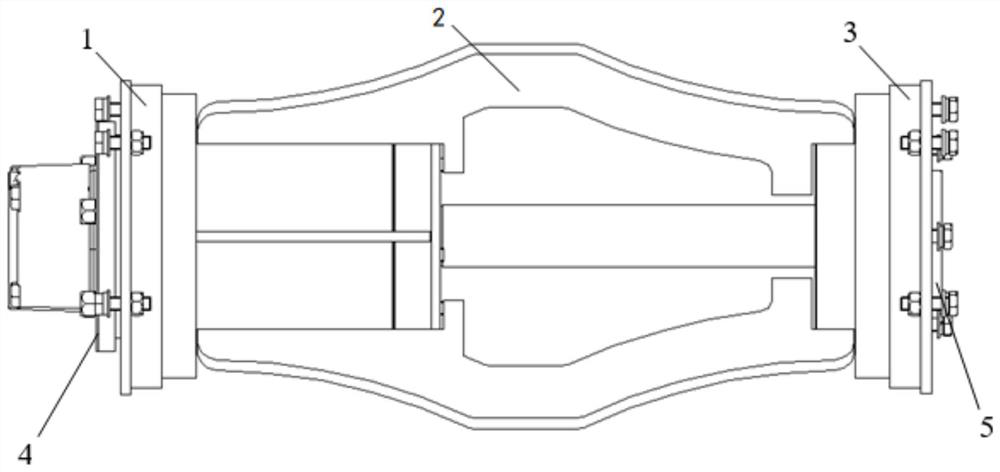

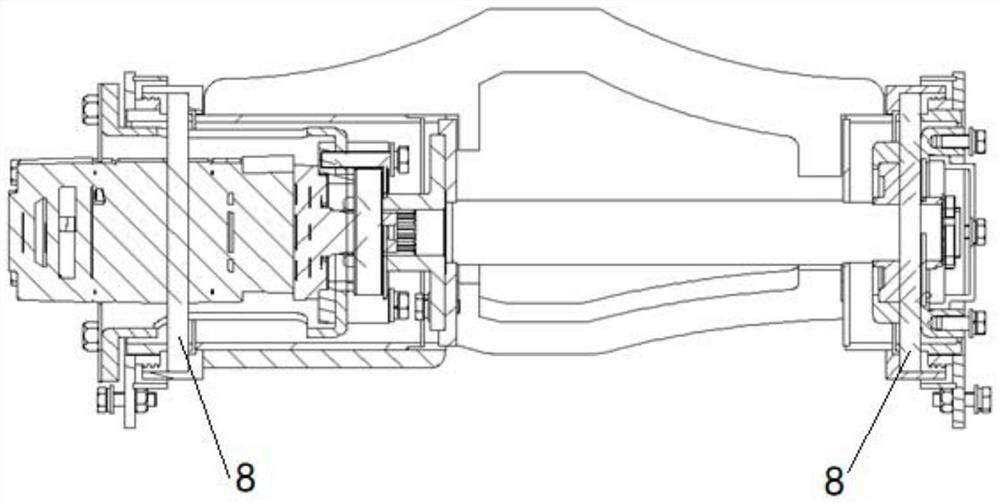

[0038] like Figure 1-Figure 2 As shown, a kind of anti-winding pick-up device provided by the present invention includes a motor end baffle welding part 1, a pick-up drum welding part 2 and a bearing end baffle welding part 3; the motor end baffle welding part 1 is installed on At the motor end, one end of the welded part 1 of the motor end baffle and the welded part 2 of the pick-up drum is connected through an oil seal 8, and the other end of the welded part 2 of the pick-up drum is connected with the welded part 3 of the baffle at the bearing end through an oil seal 8, and the welded part 3 of the bearing end The baffle welding part 3 is installed at the bearing end; the motor end baffle welding part 1, the pickup roller welding part 2 and the bearing end baffle welding part 3 form a double seal structure.

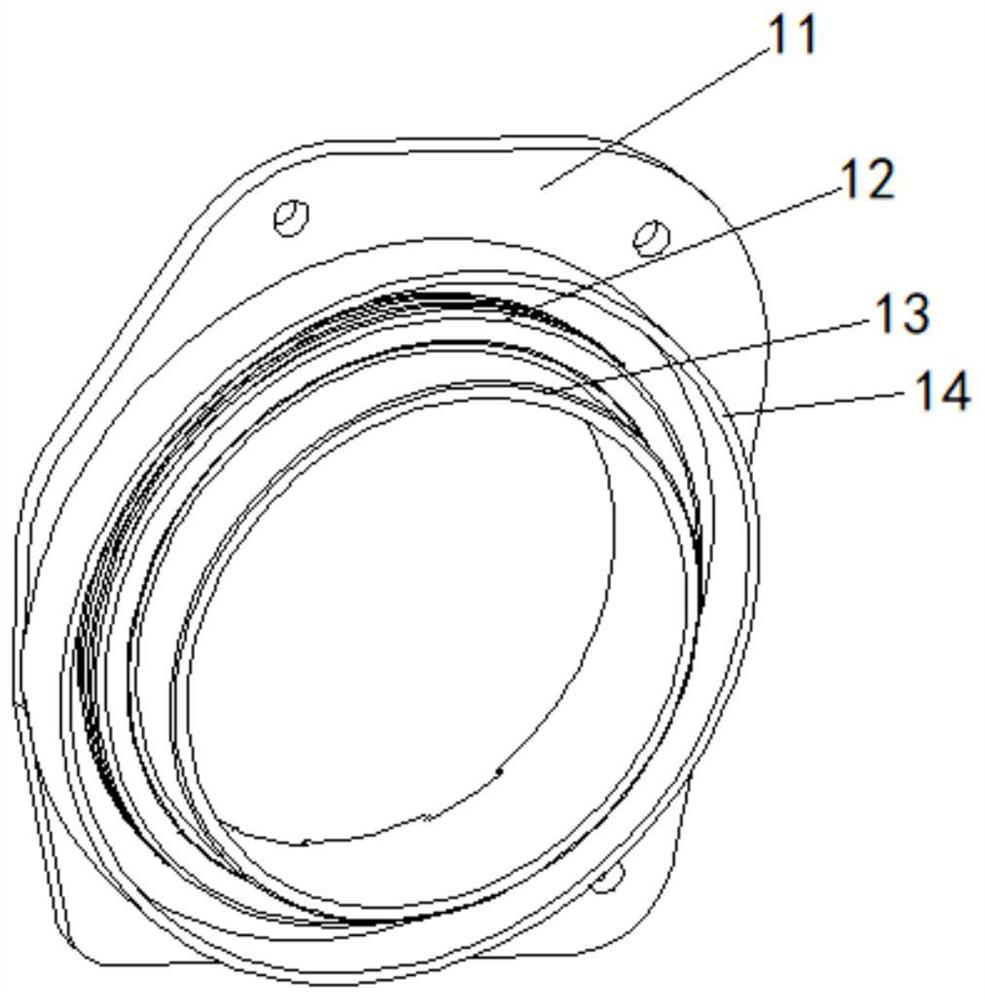

[0039] like image 3 and Figure 4As shown, the motor end baffle welding 1 includes the motor end baffle 11, the right side baffle 12, the first sleeve 13 and the fi...

Embodiment 2

[0050] like Figure 8 As shown, a harvester provided by the present invention includes a frame 6 and the anti-winding pick-up device described in the above-mentioned embodiment 1; the welded part 1 of the motor end baffle and the welded part 3 of the end baffle by the bolts and nuts respectively The connection is fixed on the side wall of the frame 6; the anti-winding pick-up device is fixed on the frame 6 by bolts, which has the advantage of being easy to replace.

[0051] The harvester with the above-mentioned anti-tangle picking device disclosed by the present invention can make the sugarcane picked up, distributed and cut off smoothly enter the next-level conveying channel during the sugarcane receiving process, reduce the sugarcane drop rate and loss rate in the picking process, increase Cutting off sugarcane harvest rate and sugar yield rate meets the requirements of sugarcane farmers and sugar factories, and the harvesting efficiency is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com