Mononuclear III-V group quantum dot and preparation method thereof

A quantum dot and single-core technology, applied in the field of single-core III-V group quantum dots and their preparation, can solve the problems of poor size uniformity and small size of quantum dots, and achieve the effects of improving stability and improving size uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present application provides a method for preparing single-core III-V quantum dots, which includes performing the following steps in sequence:

[0024] Mix group III source, first ligand and non-coordinating solvent for the first reaction to prepare cation source for epitaxy; mix group III-V group seed crystal with cation source for epitaxy for second reaction, add first anion source for The third reaction, the addition of organic acid for the fourth reaction and the addition of the second anion source for the fifth reaction. Wherein, both the first anion source and the second anion source are Group V sources.

[0025] It can be understood that the group III-V quantum dots may be InP quantum dots, InAs quantum dots, GaP quantum dots, GaAs quantum dots and so on. In this embodiment, the group III-V quantum dots are InP quantum dots or InAs quantum dots.

[0026] In this embodiment, the group III source is selected from an indium source, for example, the cation is I...

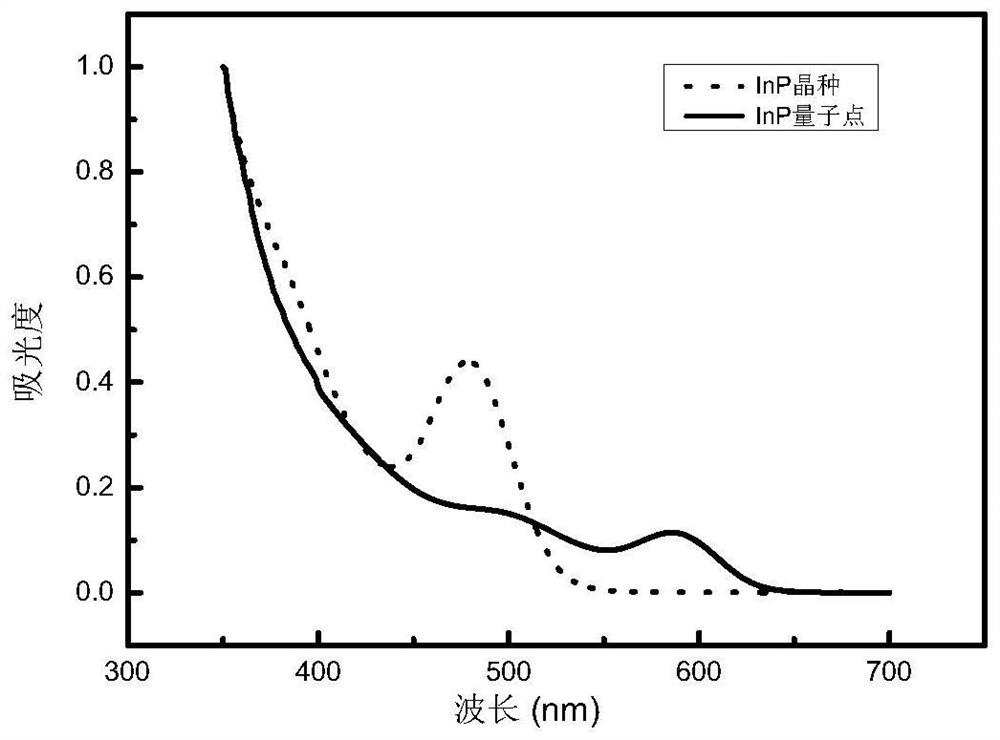

Embodiment 1

[0080] This embodiment provides a single-core InP quantum dot, which is prepared by the following steps:

[0081] (1) Add 3.6mmol of indium acetate and 10.8mmol of palmitic acid into a 100ml three-necked flask, keep it under an Ar gas atmosphere, heat it to 240°C with a heating mantle, keep it for 60min, and then cool it down to 170°C. The exhaust-intake system was changed to a vacuum system and kept for 30 minutes to obtain the indium source precursor. Rapidly inject 1.60 mmol of tri(trimethylsilyl)phosphine and 8 mmol of tri-n-octylphosphine, react for 5 minutes, then raise the temperature to 230° C. and keep for 15 minutes to finally obtain InP seed crystals.

[0082] (2) Add 18mmol of indium acetate, 14mmol of palmitic acid, 40mmol of oleic acid and 90ml of octadecene into a 250ml three-necked flask, keep it under an Ar gas atmosphere, heat it to 240°C with a heating mantle, and keep After 60 minutes, the temperature was lowered to 140°C, and the exhaust-intake system was...

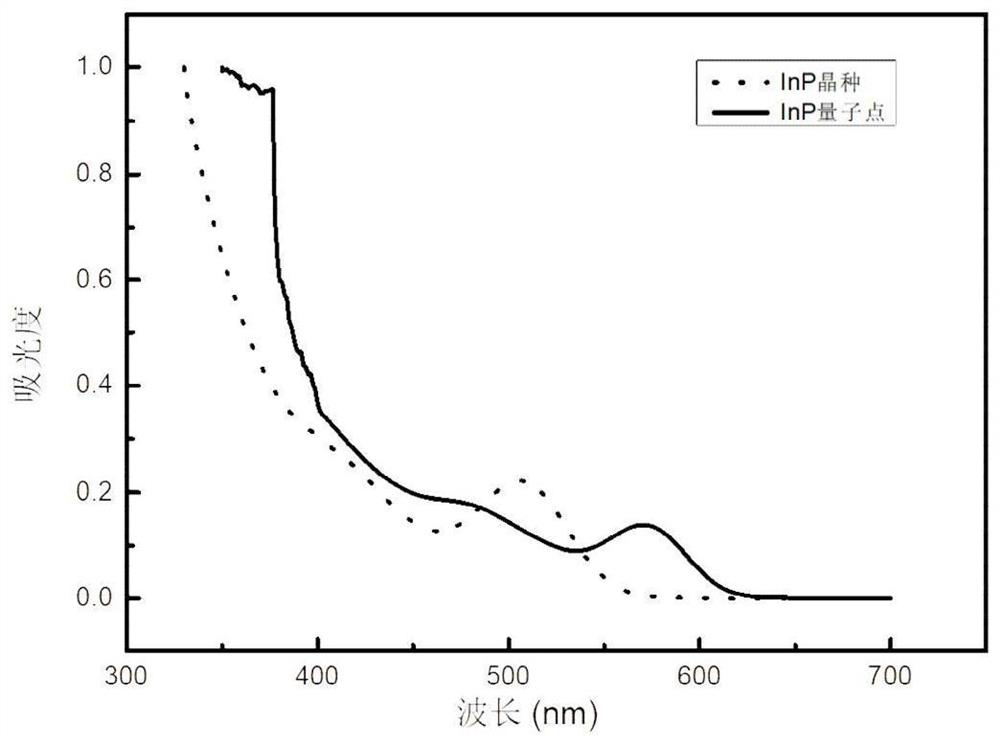

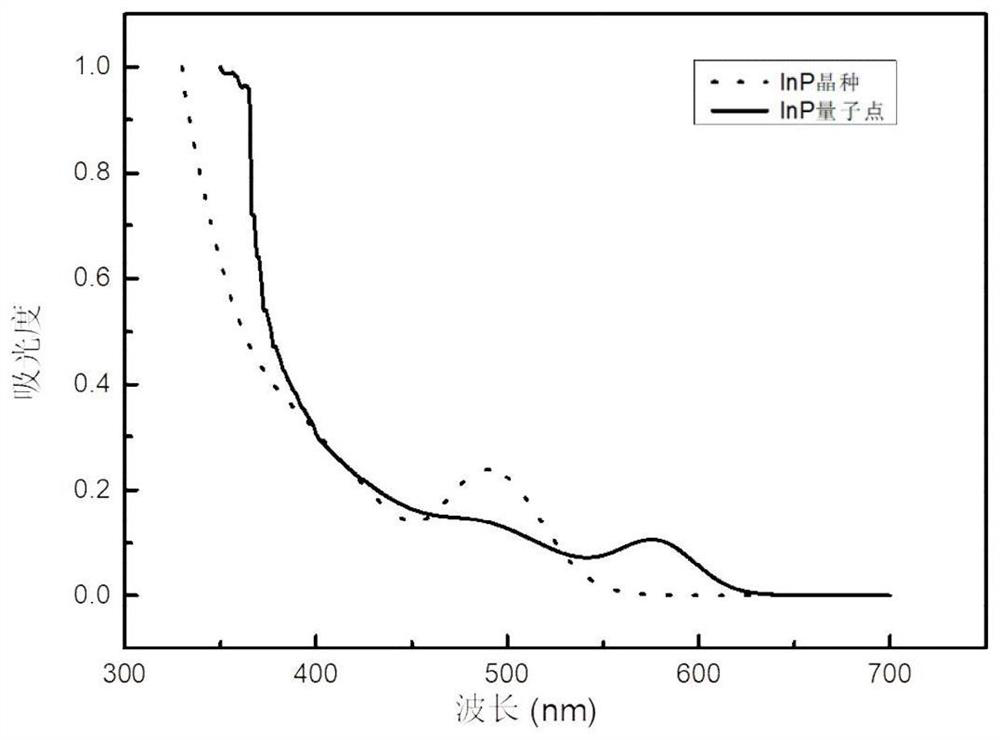

Embodiment 2

[0085] The difference between Example 2 and Example 1 is that the tris(trimethylsilyl)phosphorus in step (1) is 2.0 mmol; the oleic acid in step (3) is 0.8 mmol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com