Drying system, fibrous material drying method and carbon fiber production system

A drying system, fibrous technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of affecting the appearance quality and performance indicators of products, the horizontal drying furnace occupies a large area, and the drying effect is not good. Flue gas contaminates fibrous materials, ensures effect and uniformity, and has good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

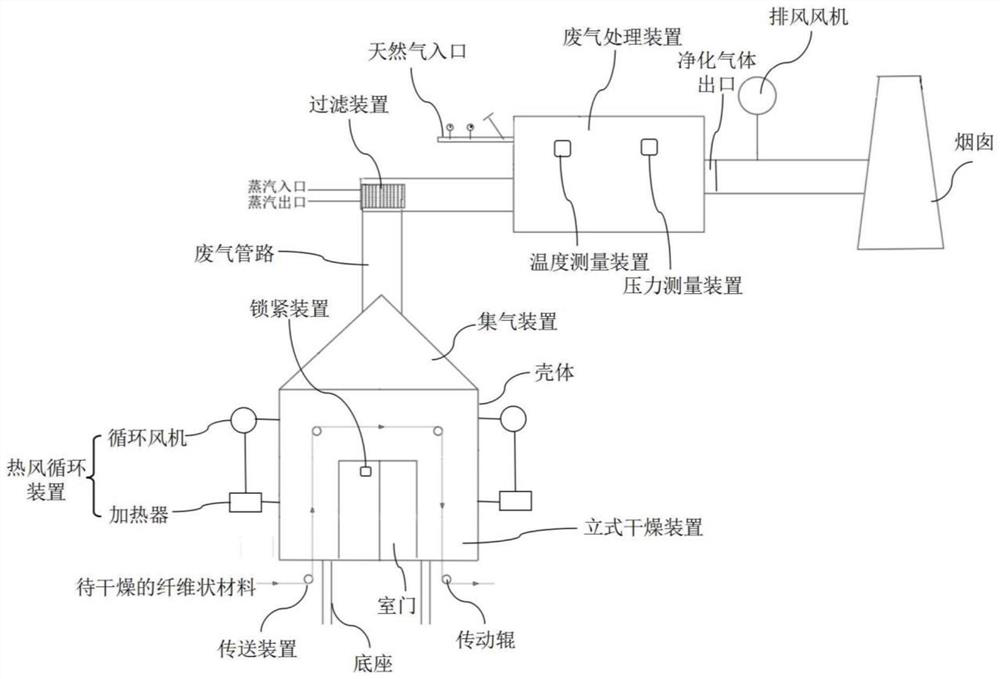

[0124] This embodiment provides a non-contact drying system for carbon fiber production, such as figure 1 As shown, the drying system includes a base, a vertical drying device arranged on the top of the base and connected to the base, a gas collecting device arranged above the vertical drying device, and a gas collecting device connected to the gas collecting device. Connected exhaust gas treatment unit.

[0125] The vertical drying device includes a housing and a conveying device at least partially arranged in the housing; the conveying device includes four driving rollers for conveying the fibrous material to be dried, wherein at least two of the driving rollers They are arranged outside the housing and respectively arranged on both sides of the base. Two transmission rollers are arranged inside the casing, the two transmission rollers are on the same plane, and are arranged at the top inside the casing; and the plane formed by the two transmission rollers is parallel to th...

experiment example

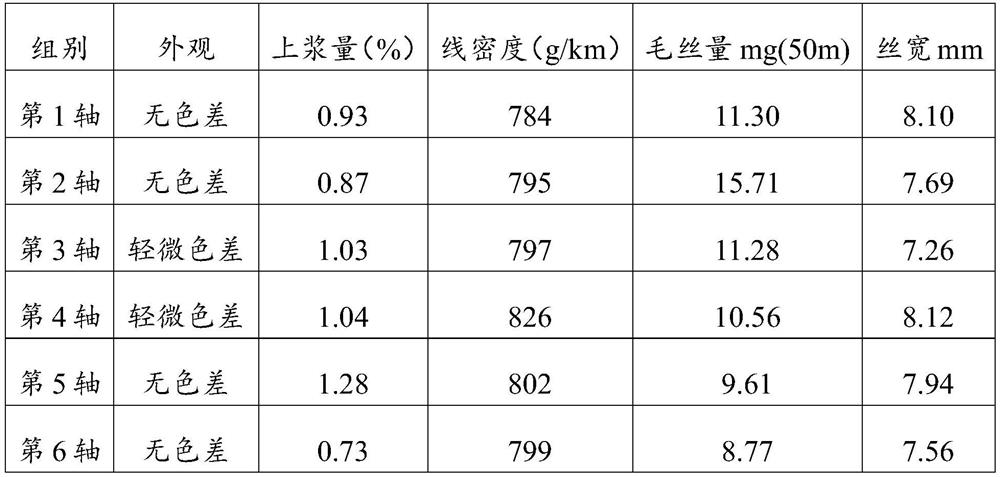

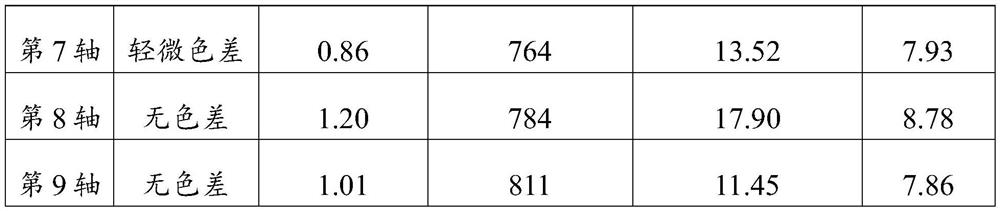

[0140] Observe and record the amount of water vapor at the inlet and outlet during the above drying process, and observe and record the state of the tow after drying. The results are as follows:

[0141] In Example 1: From the running state of the on-site tow, the inlet and outlet of the drying system (drying device) of Example 1 has no water vapor, and after the tow is dried by the drying system of Example 1, the surface of the carbon fiber material is hairless The silk is produced, the operation is stable, the drying effect is good, and the surface of the carbon fiber material has no color difference and no wrinkles.

[0142] In Comparative Example 1: Judging from the running state of the on-site tow, there is a large amount of water vapor at the inlet of the horizontal drying furnace of Comparative Example 1. After the tow is dried by the horizontal drying furnace of Comparative Example 1, the surface of the carbon fiber material has slight hairiness. Produced by silk, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com