Observation device and method for suspended sediment deposition structure in deceleration turbidity current

A technology of observation devices and monitoring devices, which is applied in the testing of machines/structural components, measuring devices, surveying and mapping, and navigation, etc. It can solve problems such as difficult formation, non-representative, and difficult to simulate turbidity fluid characteristics, so as to reduce The effect of the secondary flow structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

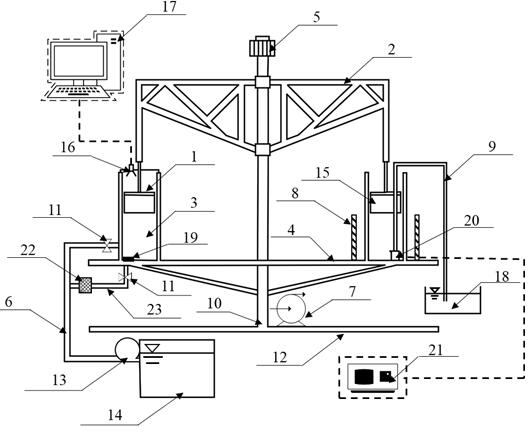

[0028] Such as figure 1 and figure 2 As shown, the embodiment of the device of the present invention is divided into a rotating water tank part, a circulating water body pipeline part, and an auxiliary monitoring device part.

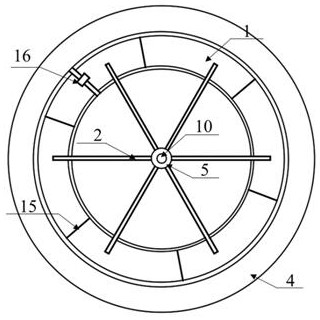

[0029] The rotating water tank part includes an acrylic transparent water tank 3, a shear ring 1, a shear ring speed control rocker arm 2, a rotatable base 4, a rocker control frequency converter 5, a rotatable base control frequency converter 7, and a center liftable metal Rod 10, base support frame 12, paddle 15 and other parts. The acrylic transparent water tank is placed on the support frame of the base and is ring-shaped; the central liftable metal rod is connected to the speed control rocker arm of the shear force ring; the speed control rocker arm of the shear force ring is connected to the shear ring with blade force ring; the rocker arm control frequency converter and the rotatable base control frequency converter respectively control the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com