Electrode plate, preparation method thereof and secondary battery formed by electrode plate

A positive electrode plate and positive electrode technology, applied in the field of secondary batteries, can solve problems such as insufficient safety, and achieve the effects of overcoming the easy dissolution of electrodes, reducing costs, and achieving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A positive pole piece, its specific preparation method is as follows:

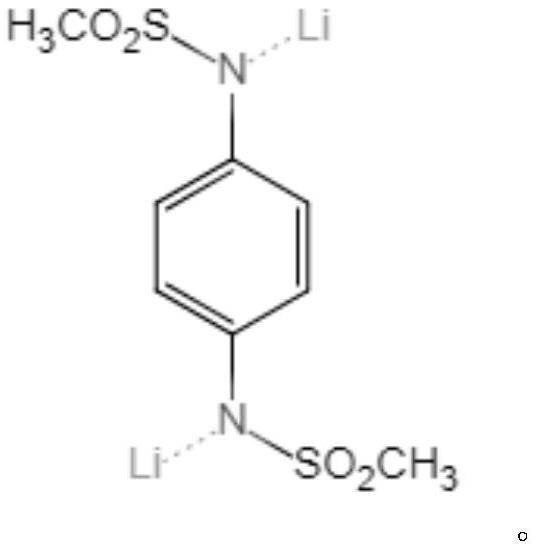

[0051] 1. Weigh 500g of NCM811 ternary material, mix it with the same mass of conjugated lithium sulfonate, add it into a ball mill jar, and the ball milling time is 1h, the ball milling speed is 1200r / min, and the mixture is obtained.

[0052] 2. Put the organic solvent NMP (N-methylpyrrolidone) in a vacuum stirred tank, add PVDF (polyvinylidene fluoride, binder), carbon black, carbon nanotubes and the above-mentioned mixture in turn, and vacuumize and stir After 6 hours, a mixed slurry was obtained. The mass ratio of the components in the mixed slurry is: ternary material: conjugated lithium sulfonate: PVDF: carbon black: carbon nanotubes = 46:46:4:3.5:0.5, the solid content of the mixed slurry is controlled At 70%.

[0053] 3. Coating on an aluminum current collector with a thickness of 12 microns, the thickness of the coating is 70 microns, drying and hot pressing to obtain the positive electr...

Embodiment 2

[0056] A positive pole piece, its specific preparation method is as follows:

[0057] 1. Weigh 500g of lithium cobaltate material, mix it with the same mass of conjugated lithium sulfonate, add it to a ball mill jar, and the ball milling time is 1h, and the ball milling speed is 1200r / min to obtain the mixture.

[0058] 2. Put NMP in a vacuum stirred tank, add PVDF, carbon black, carbon nanotubes and the above-mentioned mixture in sequence, and stir under vacuum for 6 hours to obtain a mixed slurry. The mass ratio of the components in the mixed slurry is: ternary material: conjugated lithium sulfonate: PVDF: carbon black: carbon nanotubes=46:46:4:3.5:0.5, the solid content of the mixed slurry is controlled At 70%.

[0059] 3. Coating on a 12-micron aluminum current collector with a coating thickness of 70 microns, drying and hot-pressing to obtain the positive electrode sheet.

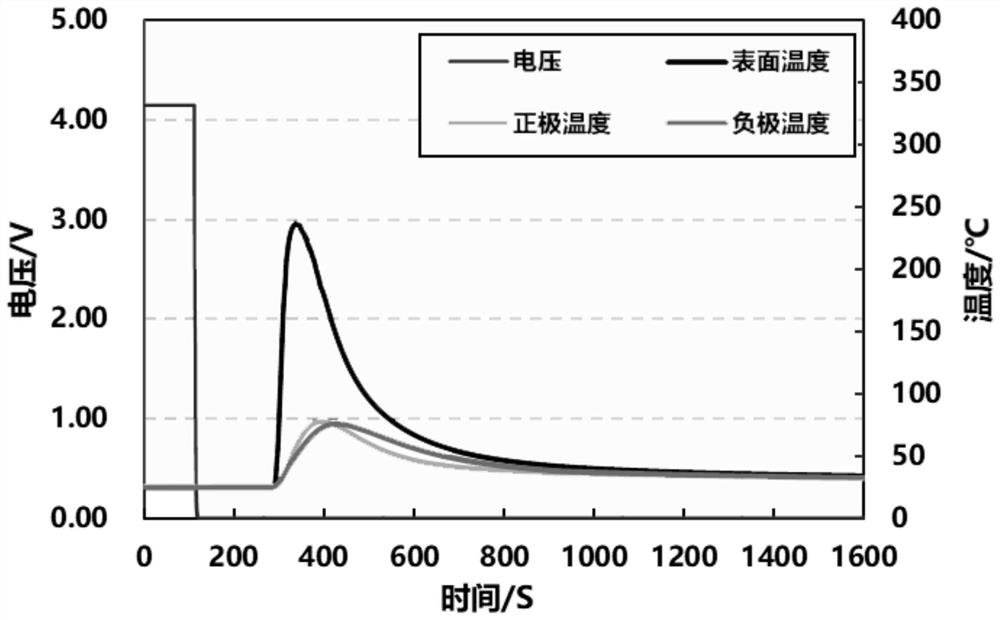

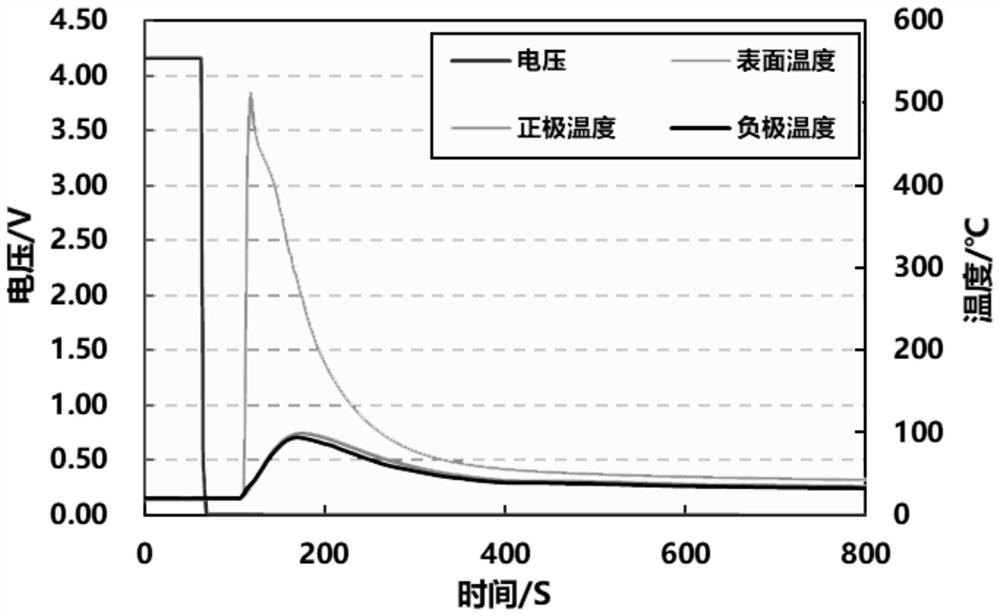

[0060] A pouch battery with a rated capacity of 5Ah was assembled using the same negative electro...

Embodiment 3

[0062] A positive pole piece, its specific preparation method is as follows:

[0063] 1. Weigh 500g of lithium iron phosphate material, mix it with the same mass of conjugated lithium sulfonate, add it into a ball mill jar, and the ball milling time is 1h, the ball milling speed is 1200r / min, and the mixture is obtained.

[0064] 2. Put NMP in a vacuum stirred tank, add PVDF, carbon black, carbon nanotubes and the above-mentioned mixture in sequence, and stir under vacuum for 6 hours to obtain a mixed slurry. The mass ratio of the components in the mixed slurry is: ternary material: conjugated lithium sulfonate: PVDF: carbon black: carbon nanotubes=46:46:4:3.5:0.5, the solid content of the mixed slurry is controlled At 70%.

[0065] 3. Coating on a 12-micron aluminum current collector with a coating thickness of 70 microns, drying and hot-pressing to obtain the positive electrode sheet.

[0066] A pouch battery with a rated capacity of 5Ah was assembled using the same negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com