Composition and method for improving melting point of colloid and edible particle

A technology of composition and granules, which is applied in the field of food manufacturing, can solve the problems of granules absorbing water and swelling, destroying the chewing feeling of granules, losing flavor and taste of granules, and achieving the effect of maintaining integrity, freshness and original taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

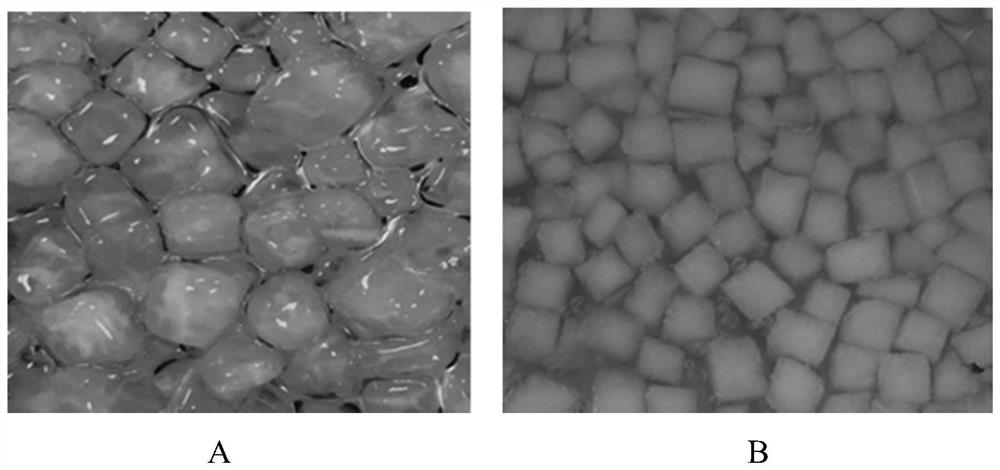

Image

Examples

Embodiment 1

[0045] The composition of the composition of this example is as follows: based on 100 kg of the composition,

raw material added amount starch 2kg calcium carbonate 2kg gellan gum 1kg citric acid 1kg water 95kg

[0046] Follow these steps to form a protective layer on the surface of the pear block:

[0047] 1. Mix starch and calcium powder (calcium carbonate powder) evenly and disperse them on the surface of the cut pear pieces. The mass of the dry base and the pear pieces is 1:100.

[0048] 2. Preparation of wet base solution: dissolve gellan gum and citric acid in water at 90°C.

[0049] 3. Add the pear pieces coated with starch and calcium powder in step 1 to the wet base part solution prepared in step 2, and stir for 1 min.

[0050] 4. Take out the pear pieces, place them in a cooling pool, and quickly cool down to below 50°C to obtain pear pieces with a protective layer.

[0051] 5. Sterilize the pear pieces with the pro...

Embodiment 2

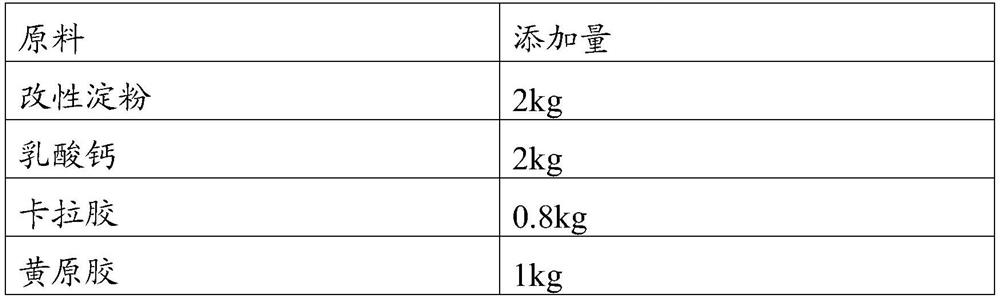

[0053] The composition of the composition of this example is as follows: based on 100 kg of the composition,

[0054] Follow the steps below to form a protective layer on the surface of the yellow peach block:

[0055] 1. Mix the modified starch and calcium lactate evenly, and wrap it on the surface of the cut yellow peach pieces. The mass of the dry base and the yellow peach pieces is 1:150.

[0056] 2. Preparation of the wet base part of the composition: Dissolve xanthan gum, carrageenan, citric acid and calcium lactate in water at 90°C.

[0057] 3. Add the yellow peach pieces coated with dry powder in step 1 to the solution prepared in step 2, and stir for 1 min.

[0058] 4. Take out the yellow peach pieces, place them in a cooling pool, and quickly cool down to below 50°C to obtain yellow peach pieces with a protective layer.

[0059] 5. Sterilize the yellow peach pieces with the protective layer under the condition of 128° C. for 15 minutes to obtain sterile yel...

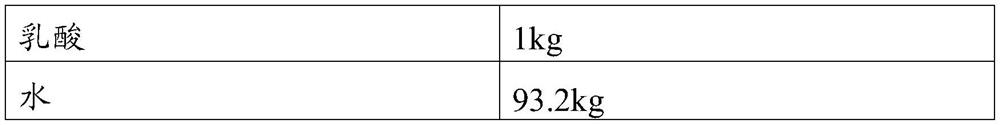

Embodiment 3

[0061] The composition of the composition of this example is as follows: based on 100 kg of the composition,

raw material added amount Modified starch 2kg Sodium chloride 2kg Carrageenan 0.5kg Locust Bean Gum 0.5kg Lactic acid 1kg water 94kg

[0062] Follow the steps below to form a protective layer on the surface of the yellow peach block:

[0063] 1. Disperse the modified starch evenly on the surface of the cut yellow peach pieces, and the mass of the modified starch and the yellow peach pieces is 1:80.

[0064] 2. Preparation of wet base part: Carrageenan, locust bean gum, lactic acid, and sodium chloride were dissolved in water at 90°C.

[0065] 3. Add the yellow peach pieces wrapped with modified starch in step 1 to the solution prepared in step 2, and stir for 1 min.

[0066] 4. Take out the yellow peach pieces, place them in a cooling pool, and quickly cool down to below 50°C to obtain yellow peach pieces with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com